Lifting column for sand irrigation

A technology of lifting columns and sandy ground, which is applied in the field of lifting columns, can solve the problems of increasing the cost of sealing caps, affecting other processes, and unsatisfactory results, and achieves the advantages of avoiding deposition, good social and economic benefits, and novel and unique structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

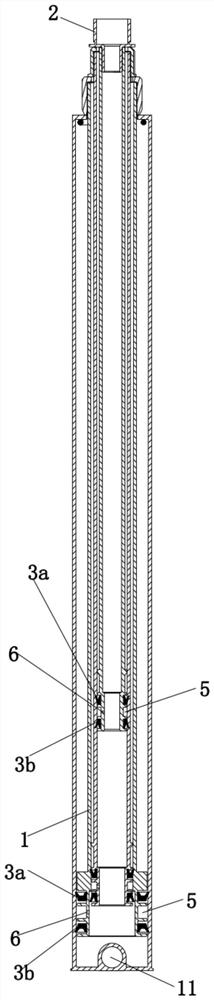

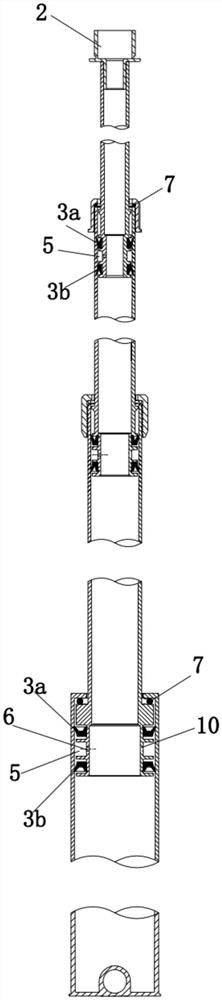

[0015] Depend on Figure 1-6 Given, the present invention is a lifting column for sand irrigation, including a base and a telescopic column main body mounted on the base, the telescopic column main body is composed of multiple sections of circular hollow tubes 1 with different diameters, and the previous section is compressed in the next section. Inside, a length-adjustable lifting column structure is formed, and each circular hollow tube 1 is a tubular hollow structure that penetrates up and down. The top center of the circular hollow tube located on the outer side, and the lower part of the circular hollow tube located on the inner side protrudes into the inner cavity of the circular hollow tube located on the outer side, and a sliding base 10 is provided on the lower outer wall extending into one end, and the top of the sliding ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com