Protective glaze suitable for firing in low-temperature fast firing kiln, ceramic tile and preparation method thereof

A technology for protecting glaze and ceramic tiles, applied in the field of ceramic glaze, can solve problems such as batch unqualified, achieve the effect of increasing manufacturing cost, avoiding unqualified and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Further, the present invention also proposes the preparation method of the above-mentioned protective glaze suitable for firing in a low-temperature fast-fired kiln, comprising the following steps:

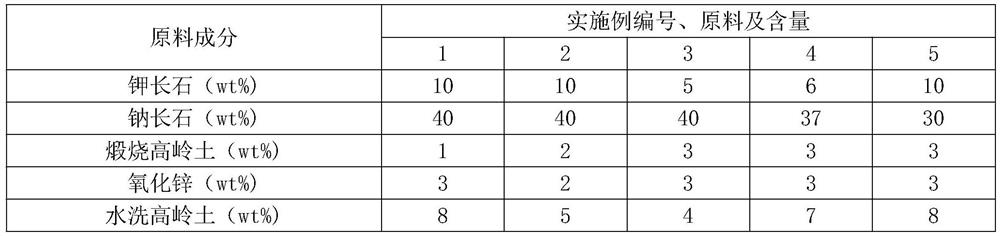

[0056] S1) According to the weight percentage calculation, respectively weigh 5-10% of potassium feldspar, 30-40% of albite feldspar, 1-3% of calcined kaolin, 2-3% of zinc oxide, 4-8% of washed kaolin, and 8% of calcined talc. -12%, 4-6% strontium carbonate, 4-6% calcite, 10-15% alumina and 5-8% dolomite, mix evenly and add an appropriate amount of hydration slurry to check that the total content of alumina meets the setting After the range, the mixture is prepared;

[0057] S2) putting the mixture into a ball mill for wet ball milling to obtain a slurry;

[0058] S3) passing the slurry through a vibrating sieve, and removing iron with a strong magnetic field, so as to obtain the glaze slurry of the protective glaze.

[0059] The above-mentioned preparation process is sim...

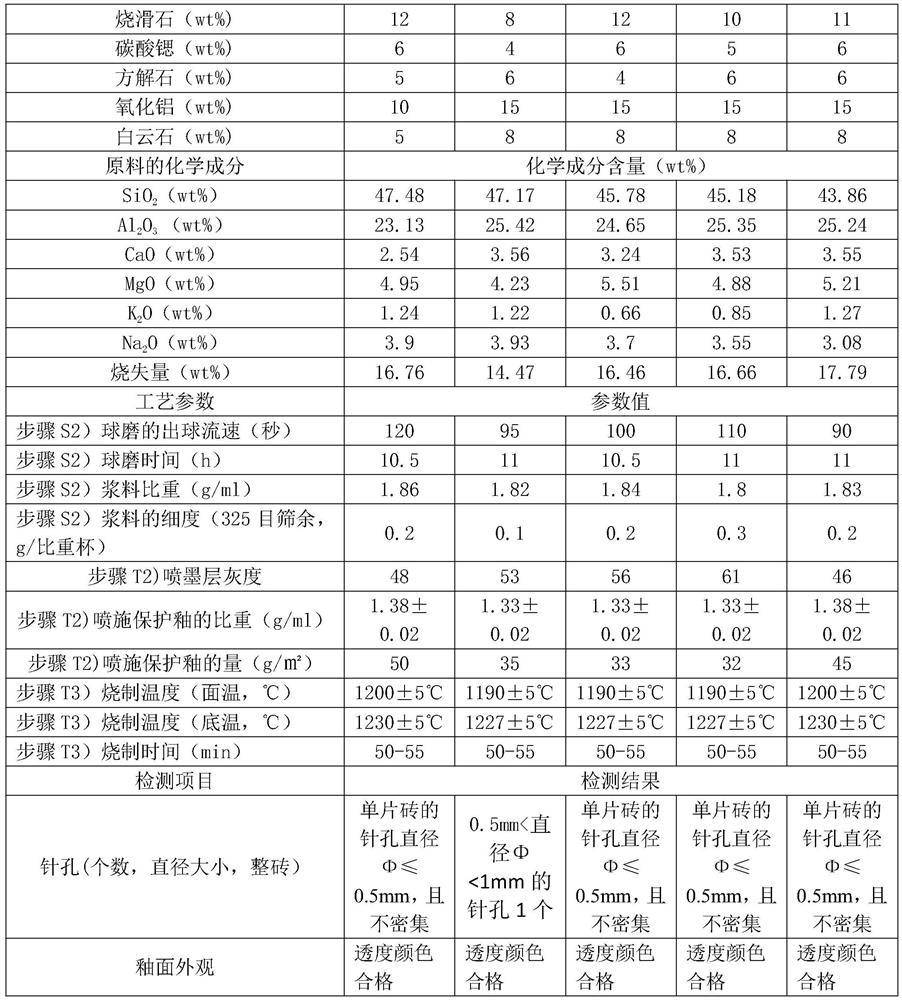

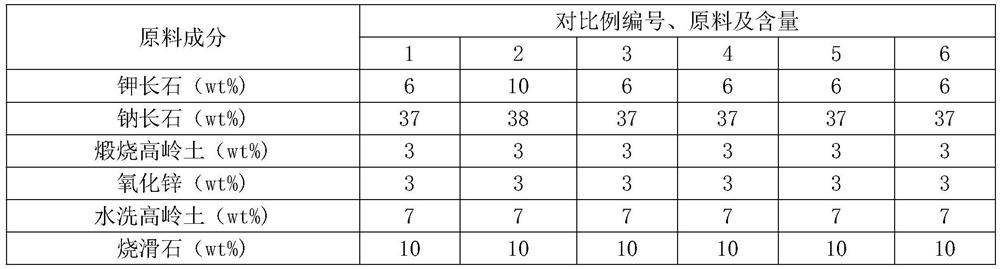

Embodiment 1-5 and comparative example 1-6

[0068] 1. The protective glaze suitable for firing in a low-temperature fast-firing kiln of each embodiment and each comparative example is prepared according to the following steps:

[0069] S1) According to the weight percentage calculation, respectively weigh 5-10% of potassium feldspar, 30-40% of albite feldspar, 1-3% of calcined kaolin, 2-3% of zinc oxide, 4-8% of washed kaolin, and 8% of calcined talc. -12%, 4-6% strontium carbonate, 4-6% calcite, 10-15% alumina and 5-8% dolomite, mix evenly and add an appropriate amount of hydration slurry to check that the total content of alumina meets the set After the range, the mixture is prepared;

[0070] S2) putting the mixture into a ball mill for wet ball milling to obtain a slurry;

[0071] S3) pass the slurry through a 160-mesh vibrating sieve, and remove iron with a strong magnetic field, so as to obtain the glaze slurry of the protective glaze;

[0072] In step S2), the flow rate of wet ball milling is 90-120 seconds, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com