Quantitative aluminum water feeding device for aluminum bar production

A technology of feeding device and aluminum bar, which is applied in metal processing equipment, manufacturing tools, equipment for supplying molten metal, etc., can solve the problems of inconvenient material leakage operation of the device, inconvenient collection and processing of excess materials, and inconvenient material anti-splash treatment, etc. To achieve the effect of improving the anti-splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

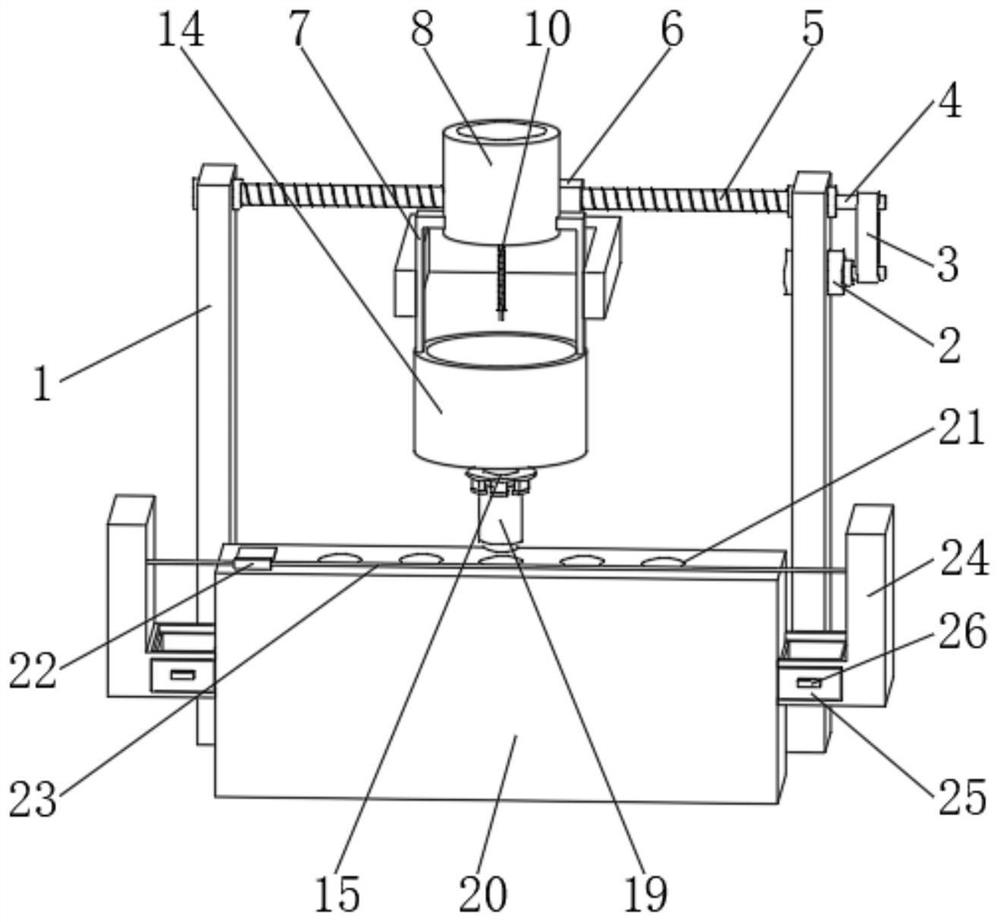

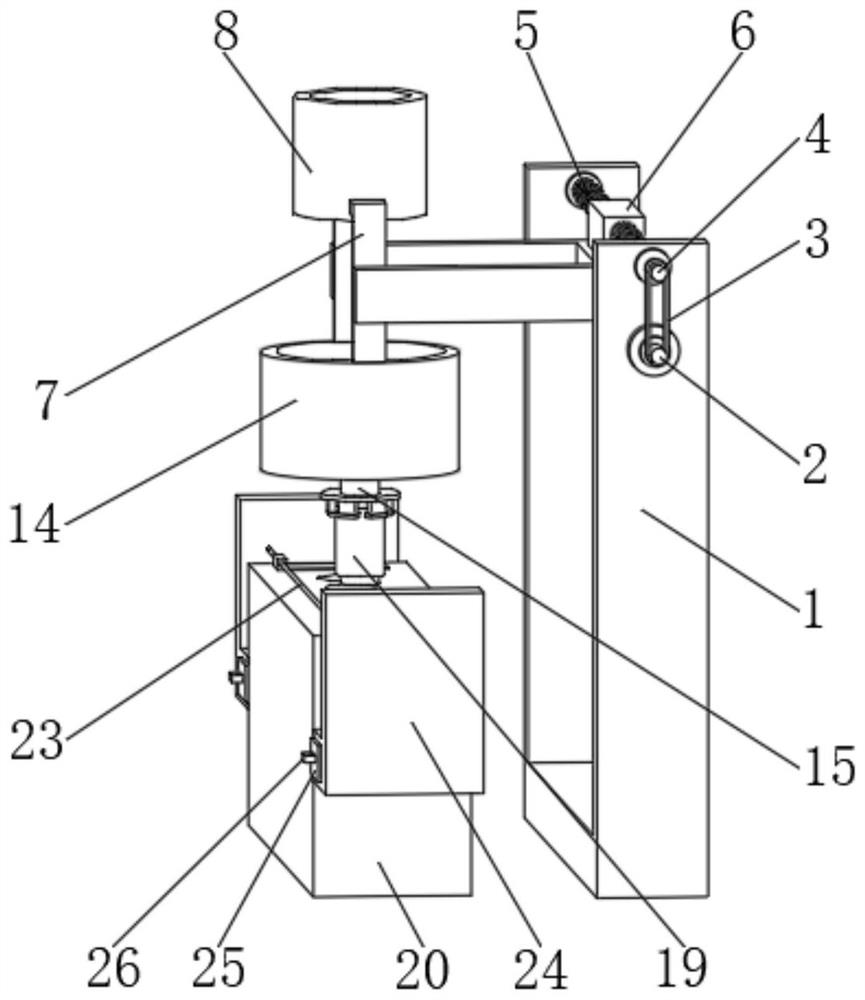

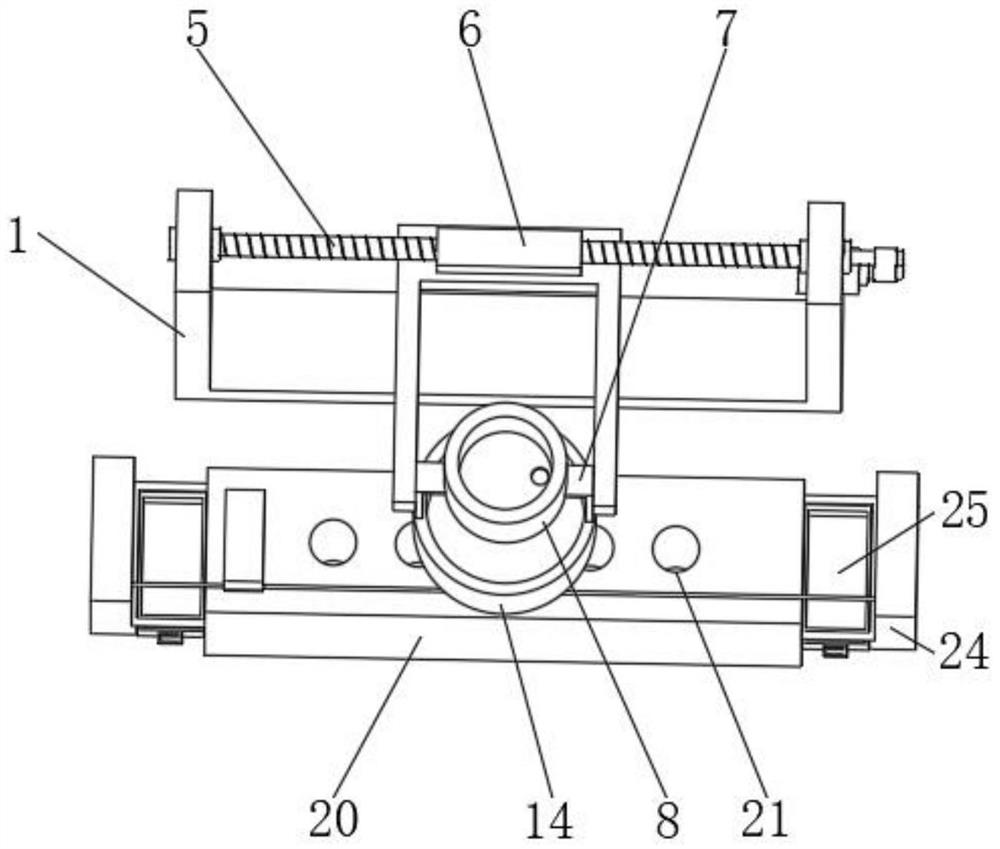

[0027] see Figure 1-5 As shown, a aluminum water quantitative feeding device for aluminum rod production includes a support frame 1 and a mold cover 20, a servo motor 2 is installed inside the support frame 1, and a belt 3 is connected to the end of the servo motor 2, and the belt 3 The end is provided with a connecting shaft 4, and the end of the connecting shaft 4 is provided with a screw mandrel 5, the outer side of the screw mandrel 5 is provided with a threaded pipe 6, and the side of the threaded pipe 6 is provided with an adapter frame 7, and the middle of the adapter frame 7 The aluminum water tank 8 is arranged at the position, and the end of the aluminum water tank 8 is provided with a threaded plate 9, the inner side of the threaded plate 9 is provided with a threaded rod 10, and the end of the threaded rod 10 is connected with an adjustment plate 11, and the adjustment plate 11 The outer wall is provided with a lower discharge plate 12, and the end of the lower di...

Embodiment 2

[0033] see Figure 1-3 As shown in Comparative Example 1, as another embodiment of the present invention, the mold cover 20 is arranged on the side of the support frame 1, and the inner side of the mold cover 20 is provided with an aluminum rod groove 21, and the top of the mold cover 20 is provided with a surplus Material shovel plate 22, and the inboard of remaining material shovel plate 22 is provided with limit rod 23, and the end of limit rod 23 is provided with fixed seat 24, and the inboard of fixed seat 24 is provided with collection drawer 25, and the end of fixed seat 24 A connecting handle 26 is provided on the upper part.

[0034] The remaining material shovel plate 22 forms a sliding structure with the mold cover 20 through the limit rod 23, and the inner side of the mold cover 20 is equidistantly provided with five aluminum rod grooves 21, and the inner diameter of the aluminum rod grooves 21 is larger than the outer diameter of the discharge pipe 15 The user ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com