High-vibration-resistance electronic detonator delay device

A technology of electronic detonator and delay device, applied in electric fuze, offensive equipment, fuze and other directions, can solve the problems of reducing explosion rejection rate, internal circuit damage, small hole spacing, etc., to expand the application environment, good anti-vibration performance, strengthen protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

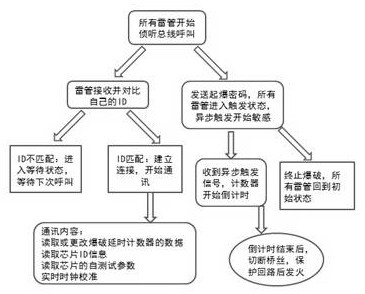

Image

Examples

Embodiment Construction

[0030] In order to make the object of the present invention and the technical solution clearer, the implementation of the present invention will be further described in detail below through specific examples and in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific implementation.

[0031] This embodiment provides an electronic detonator delay device with good anti-vibration performance, as attached figure 1 As shown, it includes pin lead-out terminals BUS1 and BUS2, an electronic delay module, and an ignition element, wherein the electronic delay module includes a current limiting unit, a rectification module, an energy storage unit, a protection circuit, a dedicated ASIC chip, and an ignition switch. Specifically, The protection circuit includes resistors R1, R2, the current limiting unit includes resistors R3, R4, the rectifier module includes diodes D1, D2, D3, D4, the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com