Drilling, jam releasing and fracturing integrated device and method for soft coal seam

A soft coal seam and fracturing technology, which is applied in the field of coal gas drainage and treatment, can solve the problems of unsatisfactory coal seam anti-permeability effect, low porosity rate, and difficult slag removal, so as to ensure drilling operation efficiency and enhance cementation , Efficient card point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

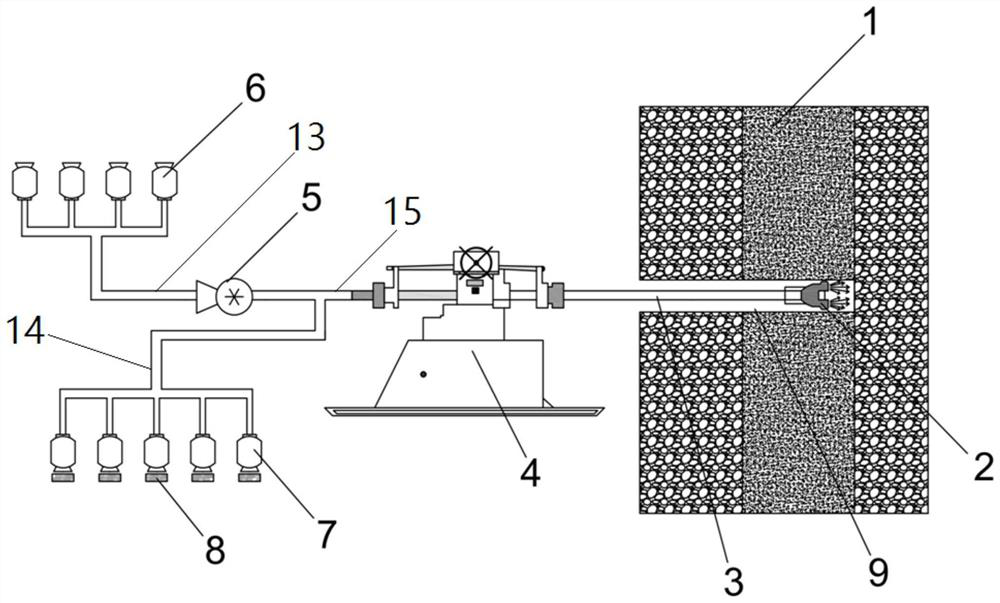

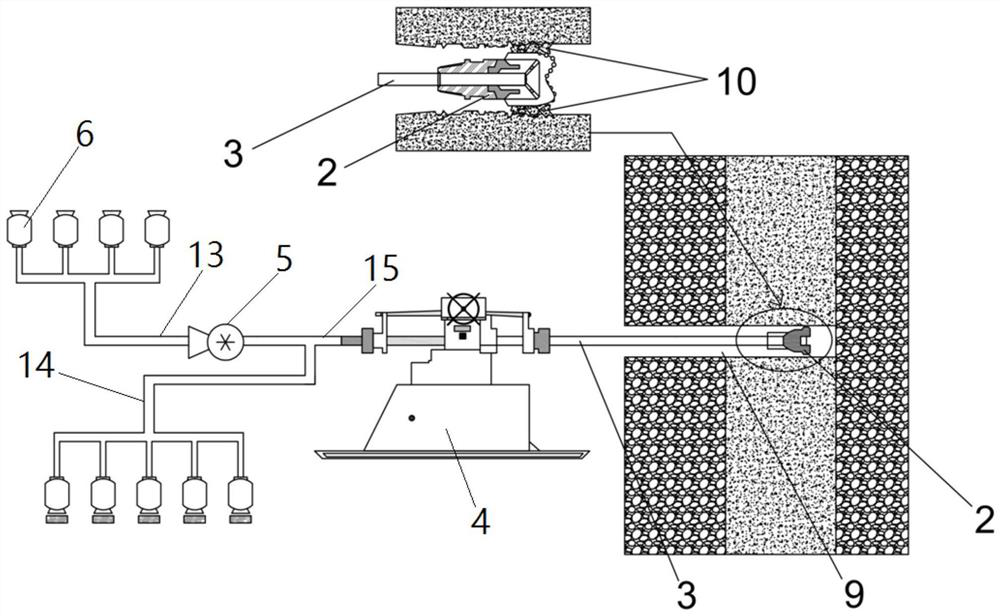

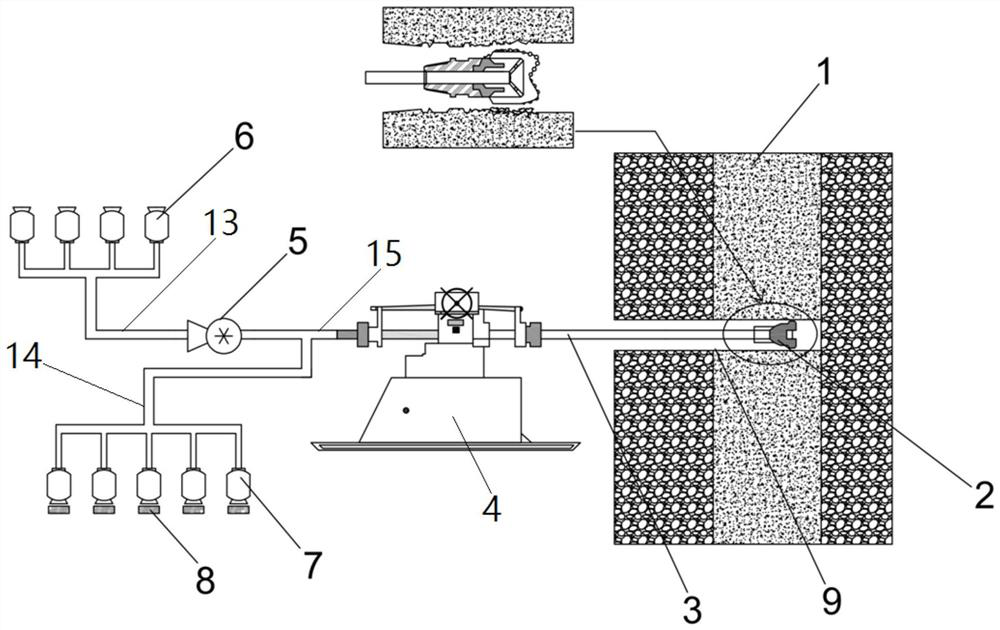

[0031] The present invention will be further described below in conjunction with accompanying drawing.

[0032] Such as figure 1 As shown, the present invention provides an integrated device for drilling, jamming and fracturing for soft coal seams, including a jet drill bit 2, a drill pipe 3, a drilling rig 4, a first set of liquid nitrogen tanks 6, a cryopump 5, The second set of liquid nitrogen tank group 7 and heater 8;

[0033] The jet drill bit 2 is installed at the outlet end of the drill rod 3; the drill rod 3 is assembled on the drill rig 4;

[0034] The first set of liquid nitrogen tank group 6 is used to provide jet medium for liquid nitrogen jet drilling, which is composed of a plurality of first liquid nitrogen tanks; each first liquid nitrogen tank is connected with a first pressure sensor, and The outlets are all connected to the first electromagnetic valve; the outlets of the first liquid nitrogen tanks are connected to the inlet of the cryopump 5 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com