A design method of mix ratio of seawater slurry with stable retaining performance

A technology of mixing ratio design and sea cement slurry is applied in the field of bored pile slurry for offshore bridge pile foundations, which can solve the problems of increasing construction cost, increasing construction cost, reducing construction efficiency, etc. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

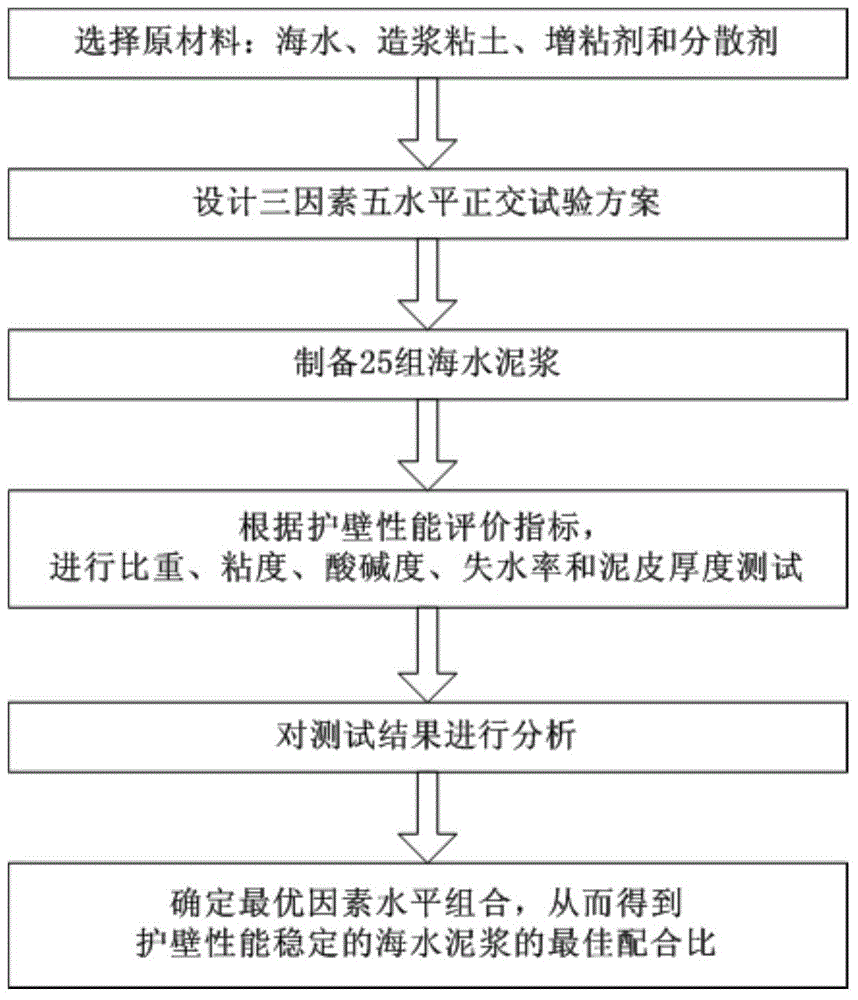

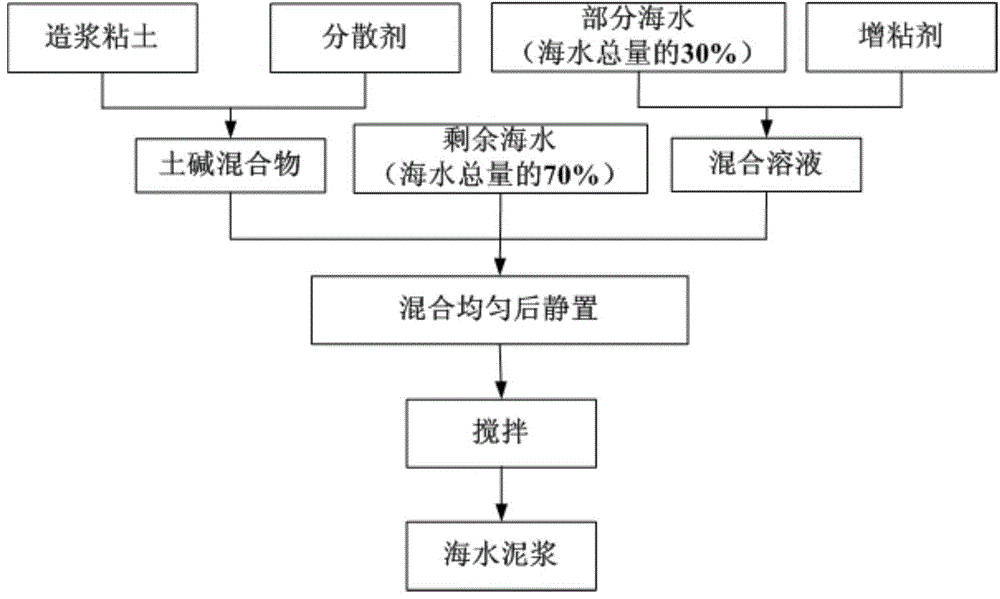

[0053] During the drilling construction of super-long pile foundation at the site of the Langqi Minjiang Bridge in Fujian Province, the applicant proposed a design method of sea cement slurry suitable for the working conditions of the Langqi Minjiang Bridge and with stable retaining wall performance. Design process such as figure 1 shown. The specific process is as follows:

[0054] Step 1. Select raw materials for seawater slurry

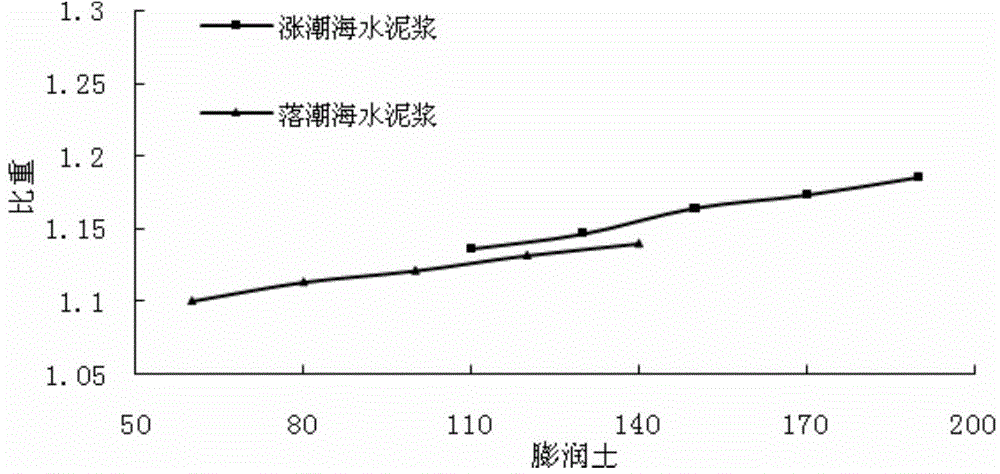

[0055] a. Selection of seawater: The natural seawater at the site of the Langqi Minjiang River Bridge was used for the test, and the natural seawater during the high tide period and the natural seawater during the low tide period were used to prepare seawater slurry. The physical and chemical indicators of the natural seawater at the site of the Langqi Minjiang Bridge are shown in Table 1.

[0056] Table 1 Physical and chemical indicators of natural seawater at the site of the Langqi Minjiang Bridge

[0057]

[0058] b. Selection of pulping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| colloid rate | aaaaa | aaaaa |

| sand content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com