Inflation mandrel supporting structure convenient to disassemble and assemble

A mandrel and structure technology, which is applied in the field of inflatable mandrel support structure, can solve the problems of increased cost of drawing, poor quality of molding appearance, waste of repaired concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

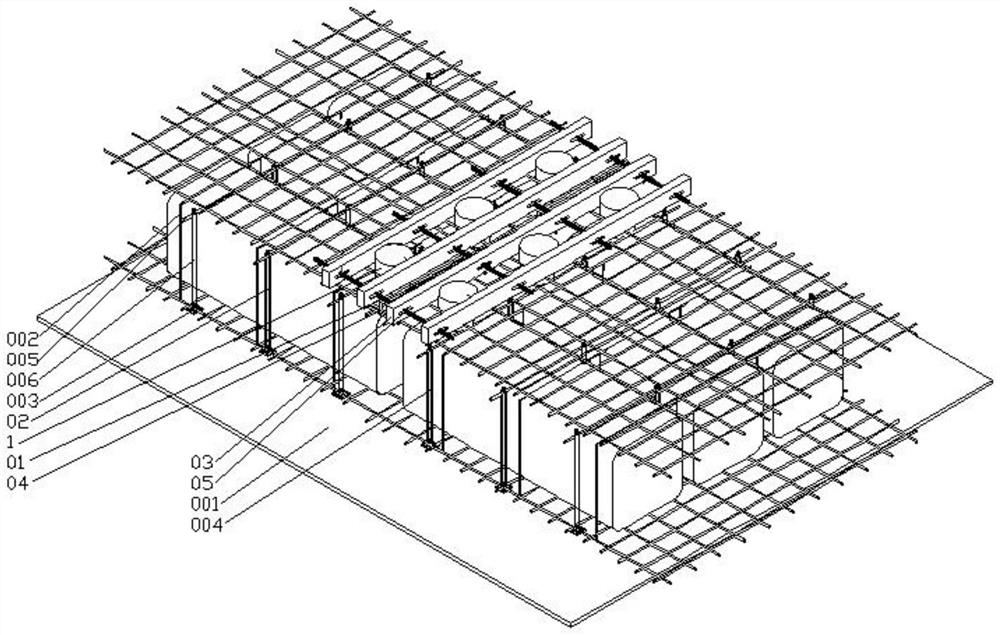

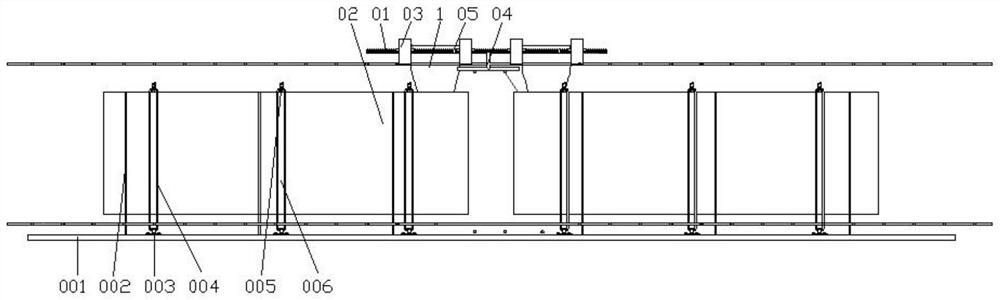

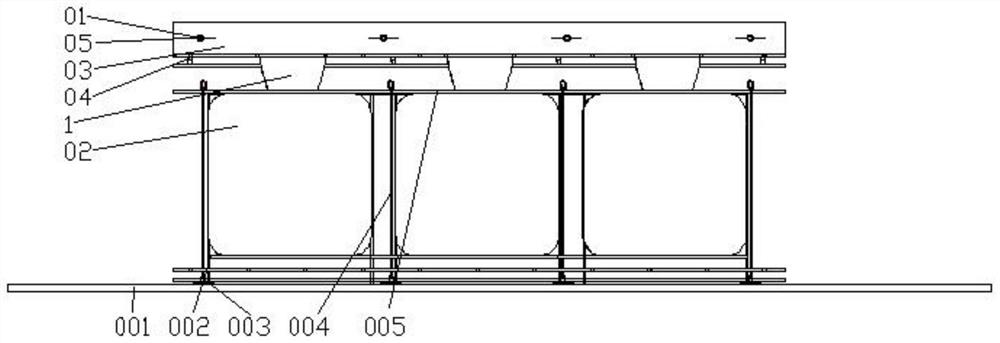

[0026] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the easy-to-disassemble inflatable mandrel support structure in this embodiment includes an inflatable mandrel installed on a preset platform, an inflation port opened on the inflatable mandrel, and an inflatable mandrel formed by the inflatable port. The protruding trachea also includes a protective cover for protecting the trachea, a stop mechanism for limiting the protective cover and a fixing mechanism for limiting the inflation mandrel to the preset platform; the axial direction is the protective cover 1, the radial direction is the radial direction of the protective cover 1, the protective cover 1 has a housing cavity 4, the protective cover 1 is arranged on the outside of the inflation port and communicates with the inflation port, so that the air pipe is arranged on the Inside the accommodation cavity 4; the protective cover 1 has a stress gap 3, and the end of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com