Cement precast pile connecting piece

A technology of prefabricated piles and connectors, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve problems such as insufficient connection strength of steel bar skeletons, easy breakage of steel bar joints, and insufficient connection strength, so as to achieve enhanced strength and ensure integrity performance and reliability, and the effect of strengthening connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

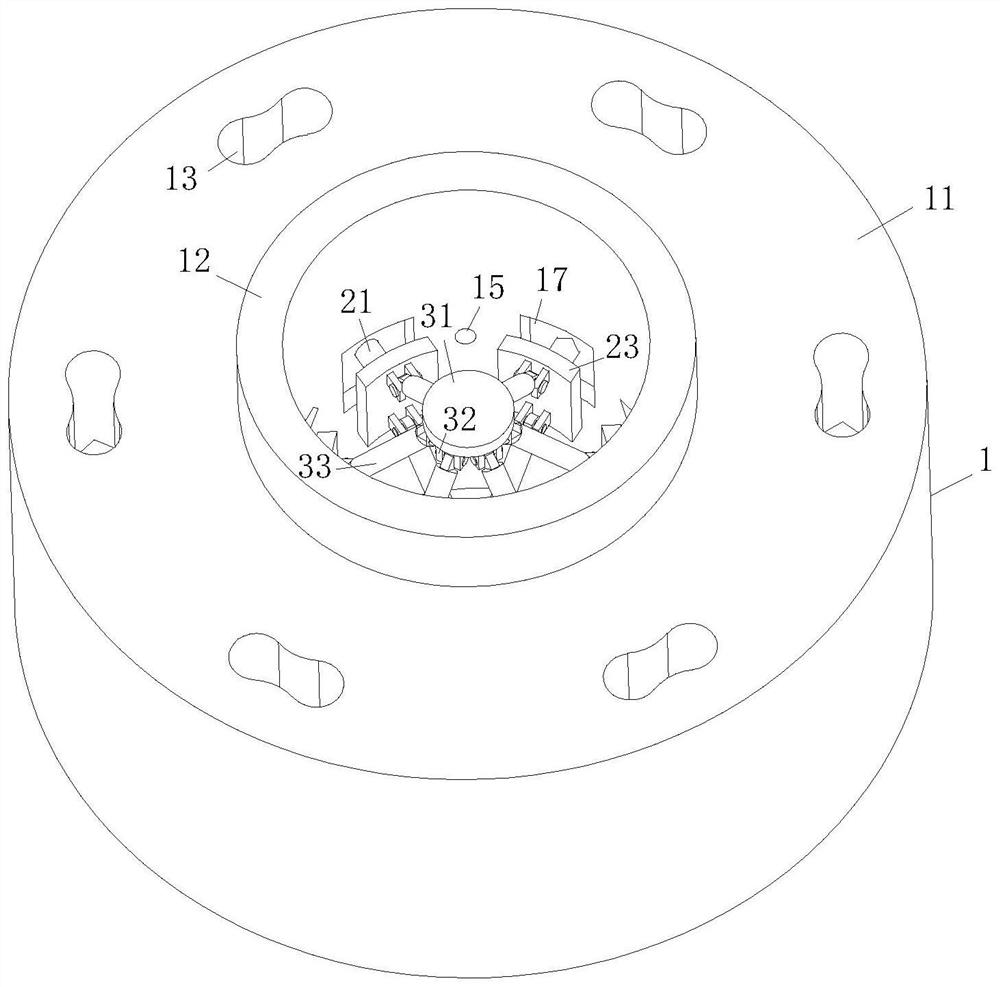

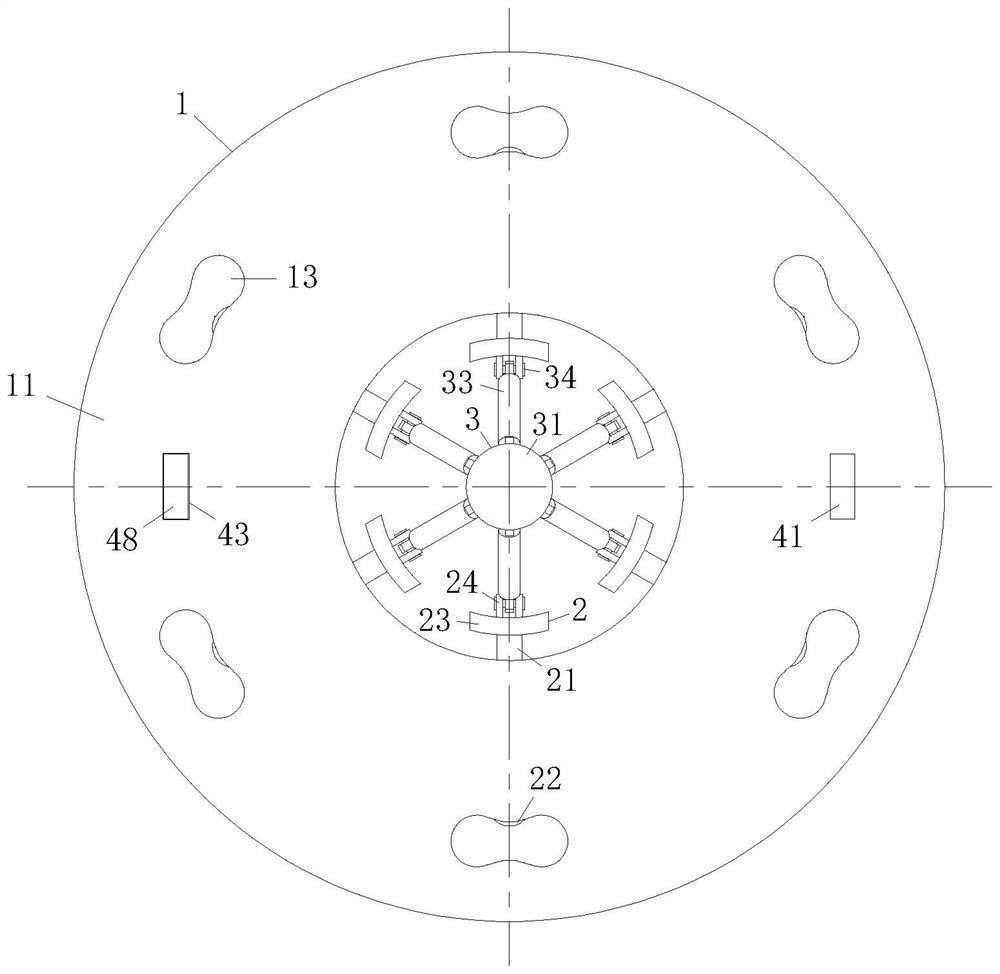

[0026] like Figure 1-Figure 6 As shown, a cement prefabricated pile connector according to the present invention includes a fixing mechanism 1, a reinforcing mechanism 2, a linkage mechanism 3 and a connecting mechanism 4; the reinforcement mechanism 2 is movably installed inside the fixing mechanism 1, and the linkage mechanism 3 is installed on Inside the mechanism 1, the linkage mechanism 3 is movably connected with the reinforcing mechanism 2, and the connecting mechanism 4 is installed on the upper end surface of the fixing mechanism 1; One end of the slot 111 is provided with a snap ring 12; the connecting pile 11 is provided with six penetrating through-holes 13 at equal intervals, and a pouring channel 14 is arranged between the two throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com