Shared self-service heat transfer printing system and method

A thermal transfer, self-service technology, applied in transfer printing, rotary printing machines, copy/marking methods, etc., can solve the problems of lack of safety protection measures, inability to achieve shared self-service printing, unfavorable promotion and application, etc. Small area, labor saving, and simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

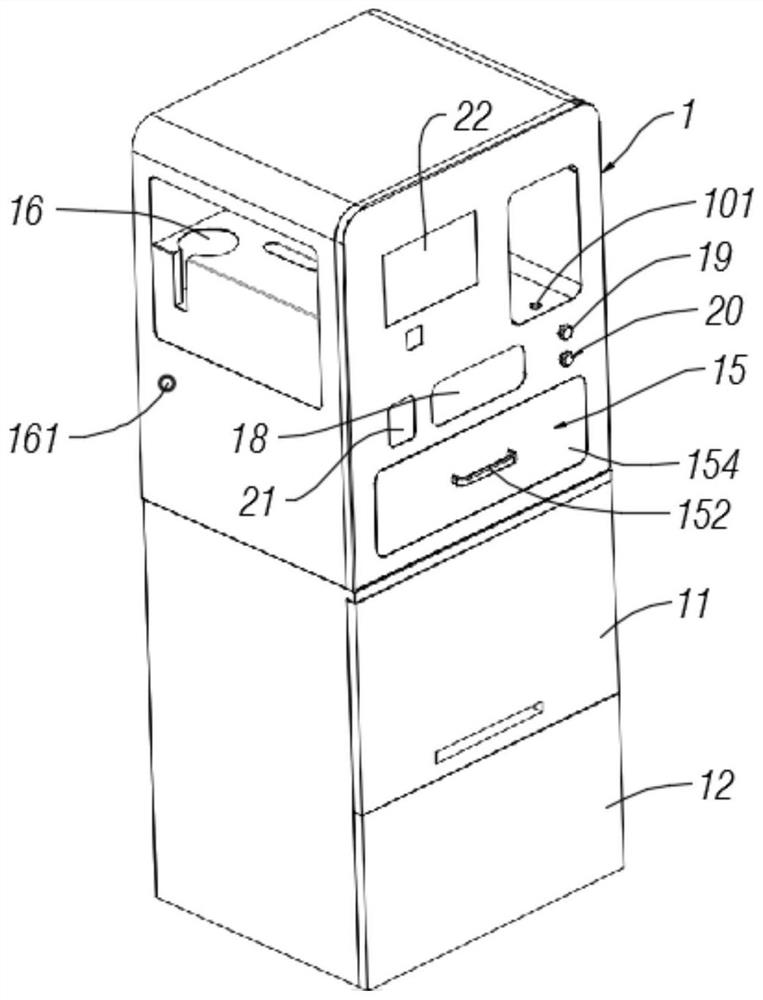

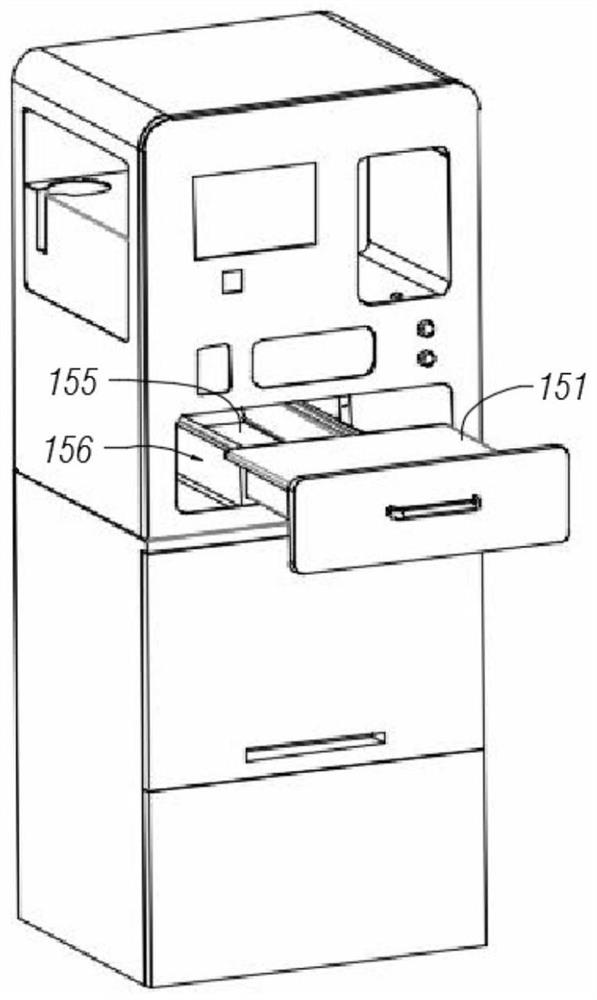

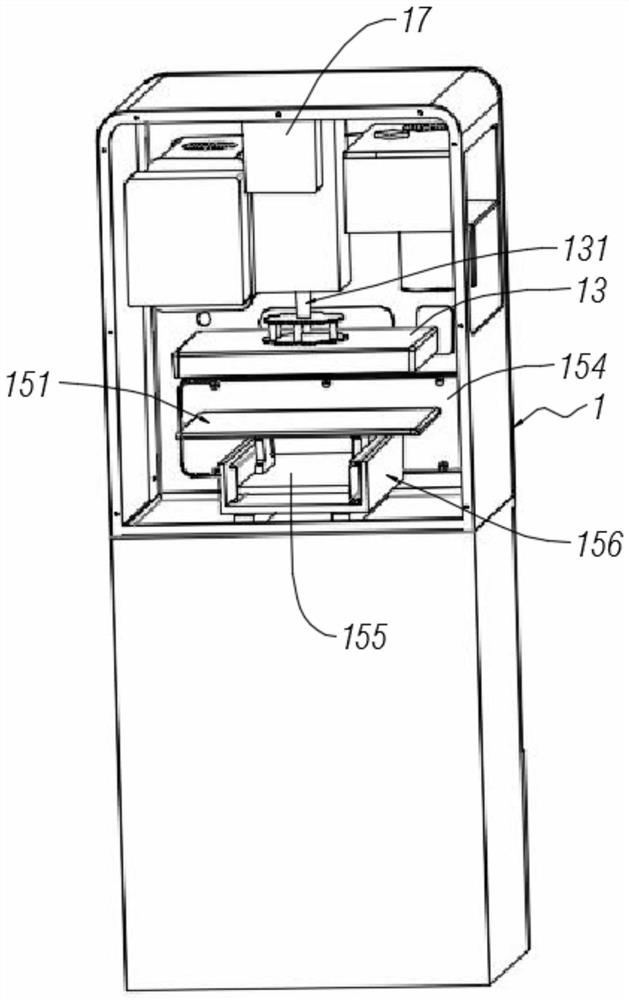

[0033] like Figure 1 to Figure 3 As shown, a shared self-service heat transfer system of the present invention includes heat transfer equipment and a background management system. The device is remotely controlled and provides background service support.

[0034] The background management system includes an information display module, an AI image design module, a payment module, an equipment management module, a hot stamping management module, a merchant management module, an order management module, and a statistical chart module. Among them, the information display module is used to display printed items and Pictures to be printed, such as displaying canvas bags, photo frames, pendants, water cups and other printed items for users to choose (this embodiment is applicable to a wide range of printed items, including a variety of common items in life, such as T-shirts, sweaters, canvas bags, school utensils Bags, pillows and other textiles; mugs, color-changing cups, thermos ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com