Texture preparation method of cover plate, cover plate and electronic equipment

A technology of electronic equipment and cover plate, which is applied in the direction of electrical equipment casing/cabinet/drawer, microlithography exposure equipment, electrical components, etc., and can solve the problem that the texture of the cover plate cannot be refined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

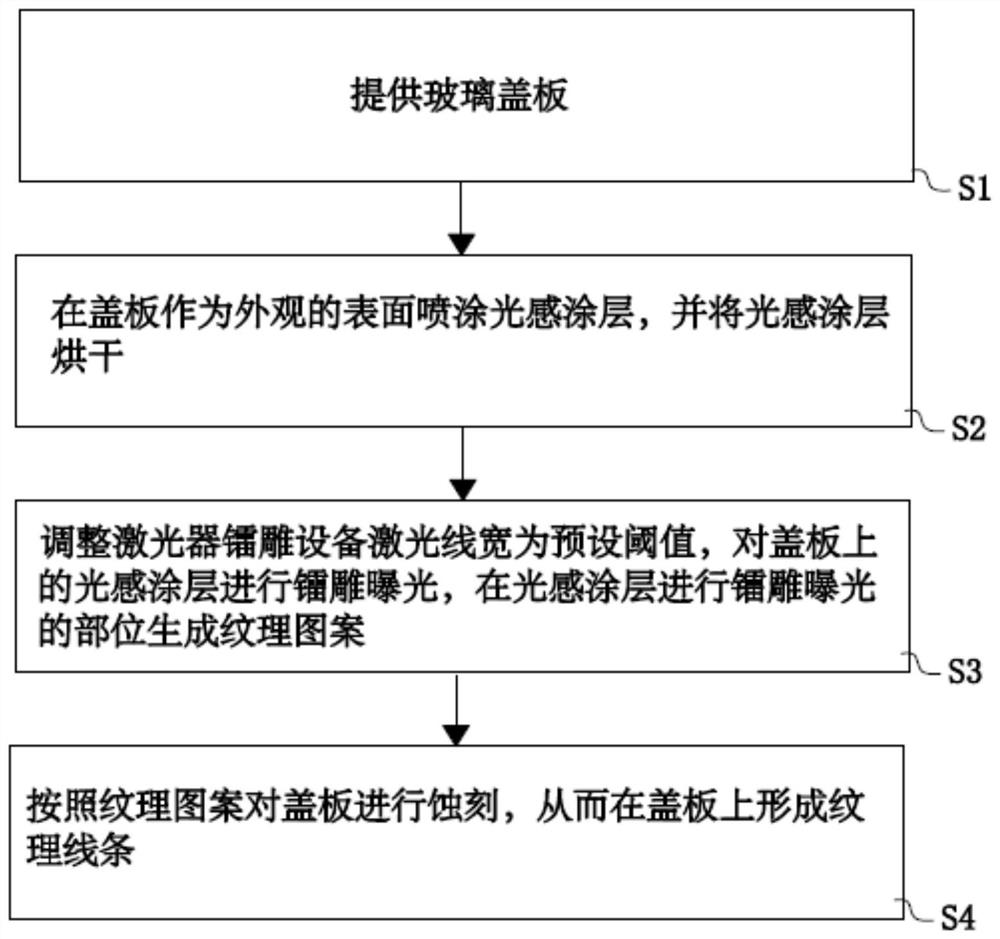

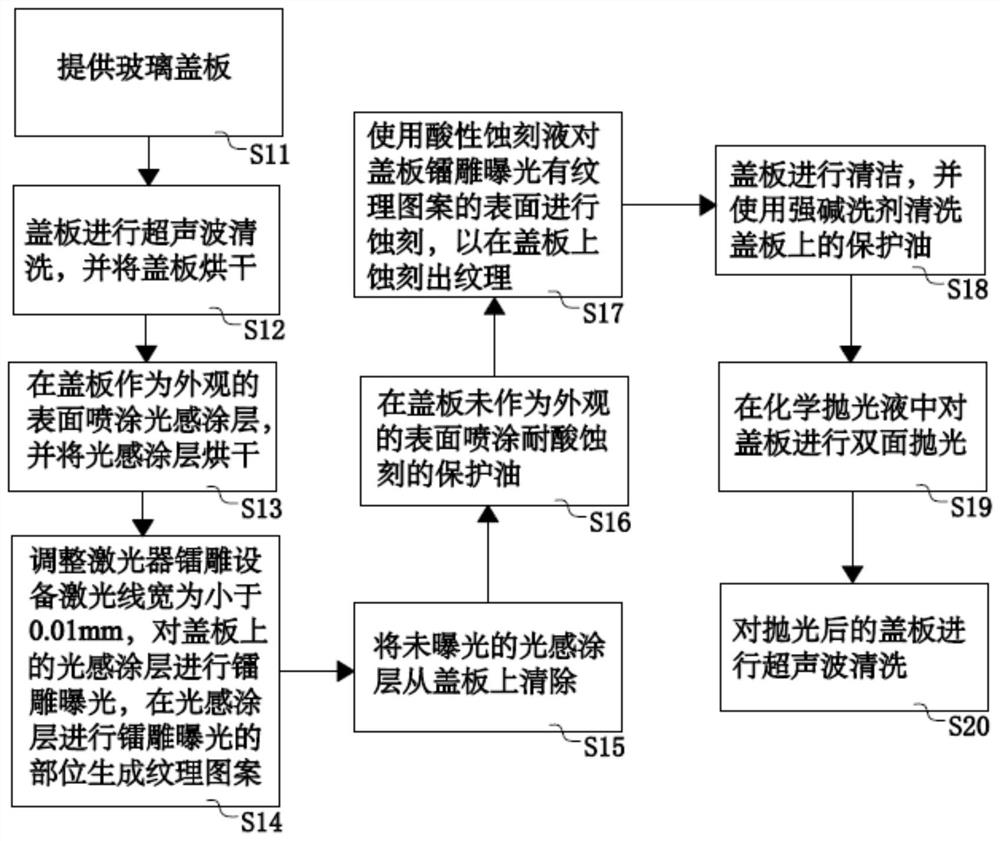

[0018] see figure 1 , the embodiment of the present application provides a method for preparing a cover plate texture, comprising the following steps: S1, providing a cover plate; S2, spraying a photosensitive coating on the surface of the cover plate as an appearance, and drying the photosensitive coating; S3 1. Adjust the laser line width of the laser engraving equipment to a preset threshold, perform radium engraving exposure on the light-sensitive coating on the cover plate, and generate a texture pattern at the part where the light-sensitive coating is subjected to laser engraving exposure; S4, according to the texture pattern on the cover The plate is etched to form textured lines on the cover plate.

[0019] In this embodiment, the preset threshold of the laser line width preset threshold is 0.01 mm. When preparing the texture on the cover plate, the laser is emitted by adjusting the width of the laser on one laser or using lasers with different laser widths. A laser w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com