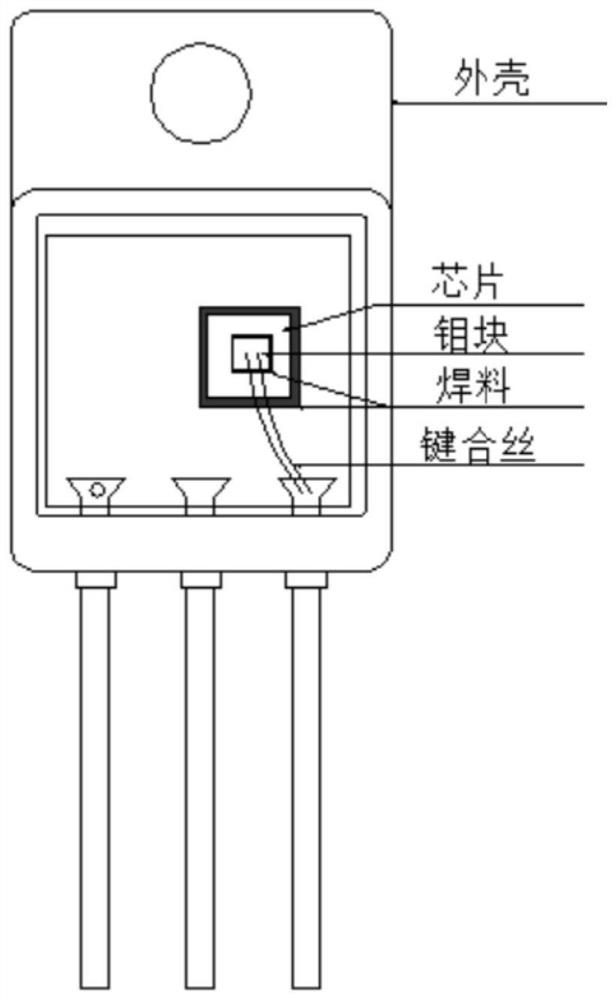

Bonding packaging structure of diode and process thereof

A packaging structure, diode technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of uneven current flow, low chip bonding reliability, mismatching thermal expansion coefficient, etc., and achieve electrical performance Normal, guaranteed long-term reliability, suitable for soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] This embodiment provides a bonding packaging process for the bonding packaging structure of the diode described in Embodiment +, including:

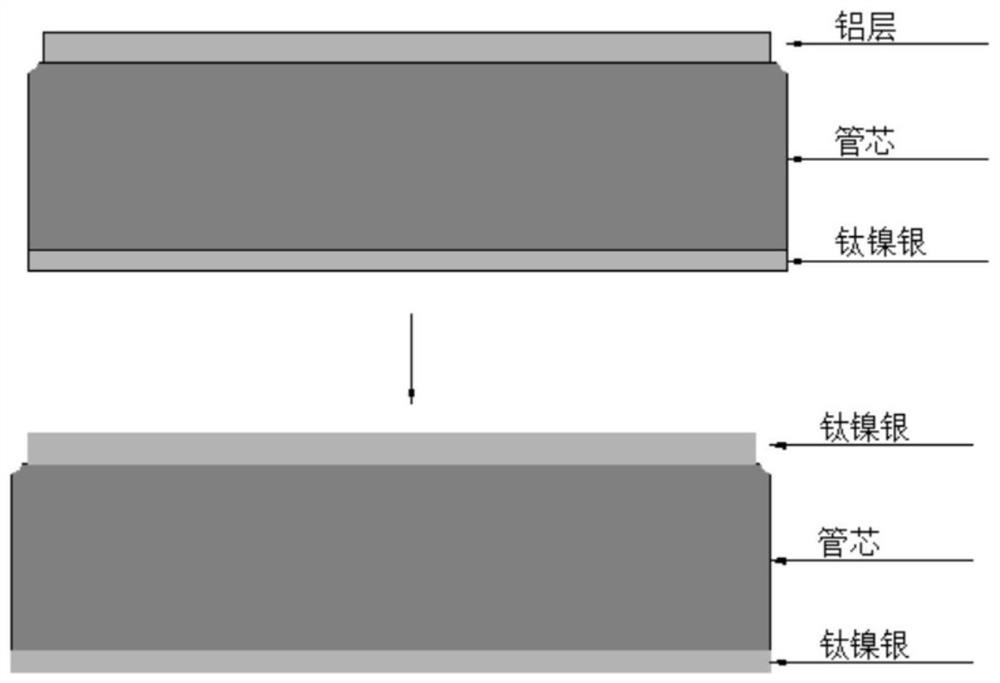

[0057] Metallize the chip with titanium-nickel-silver;

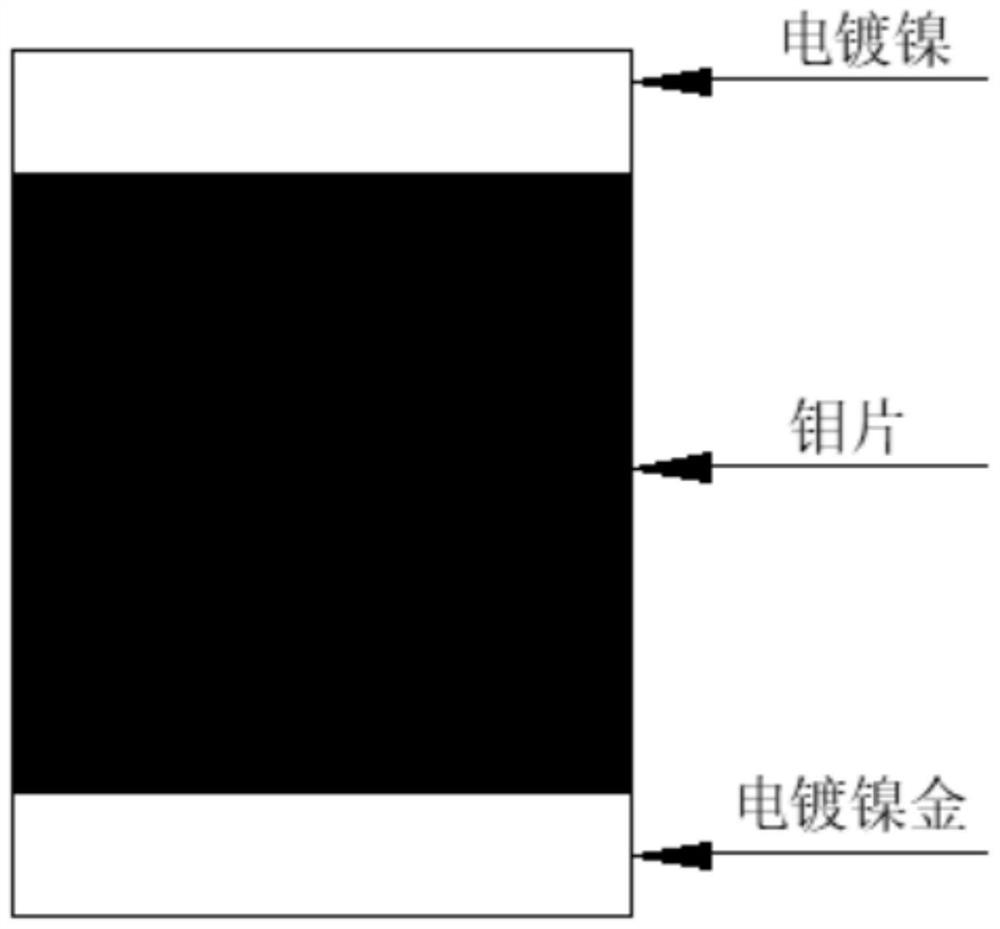

[0058] Metallization of the welding surface and the bonding surface of the molybdenum sheet, wherein the welding surface of the molybdenum sheet is electroplated with nickel gold, and the bonding surface of the molybdenum sheet is electroplated with nickel;

[0059] Vacuum welding the welding surface of the molybdenum sheet and the chip;

[0060] Ultrasonic bonding is performed on the bonding surface of the molybdenum sheet and the bonding wire.

[0061] This embodiment adopts the vacuum welding transition piece process to ensure the bonding quality. The process of metallizing titanium nickel silver is carried out on the chip surface, and the transition piece is vacuum welded on the chip surface. The welding and bonding process of the transition piece not only ensures the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com