Transformer oil monitoring system and monitoring method thereof

A technology of transformer oil and monitoring system, applied in the field of transformers, can solve the problems of single monitoring function, inability to monitor the transformer oil tank, low safety, etc., and achieve the effect of improving safety performance, protecting normal operation, and ensuring normal transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

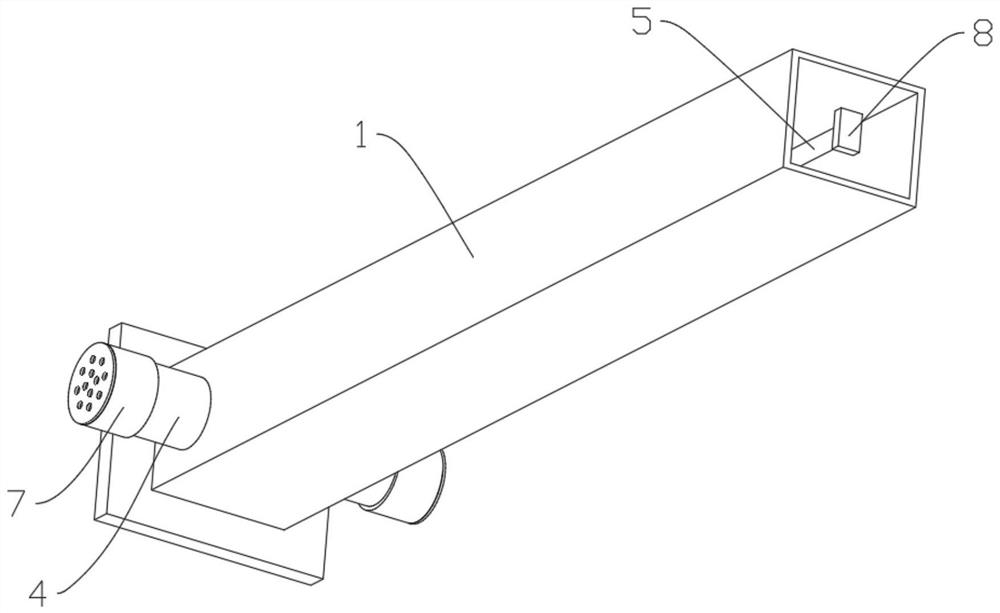

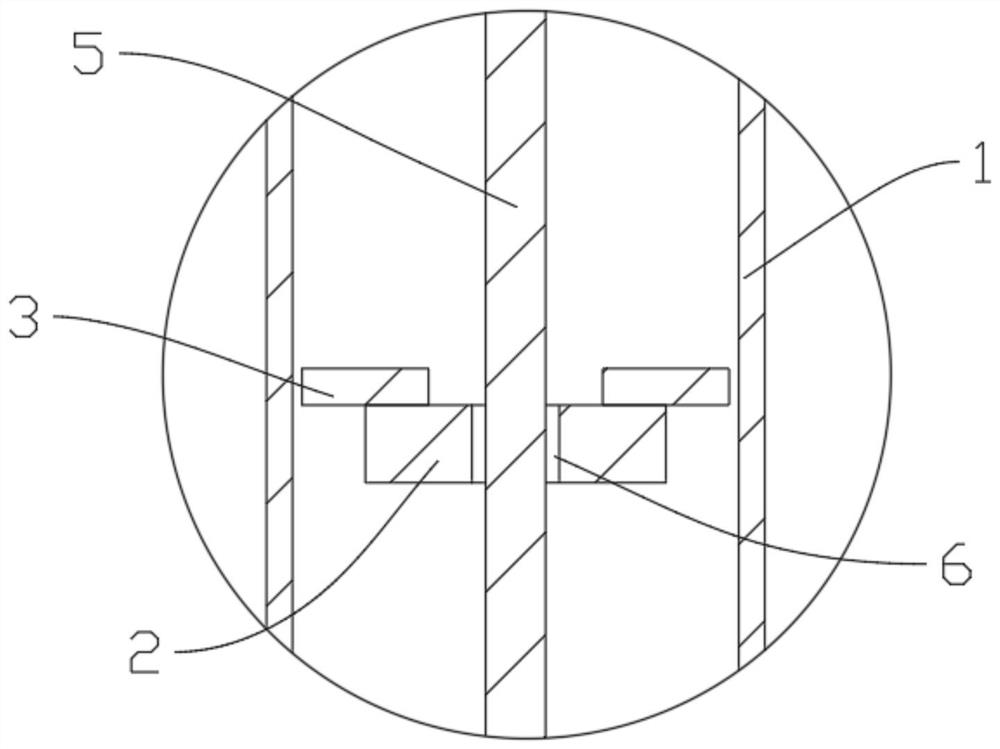

[0035] A transformer oil monitoring system, comprising:

[0036] A liquid level monitoring module installed inside the transformer oil tank for monitoring the transformer oil level, a temperature monitoring module for monitoring the temperature of the transformer oil, a pressure monitoring module for monitoring the internal pressure of the transformer oil tank, and a monitoring module for monitoring whether the transformer oil leaks Leak monitoring module;

[0037] A gas monitoring module installed at the transformer oil tank port for detecting leakage gas;

[0038] The signal transmission module and server module are set in the transformer storage room. The signal transmission module is set inside the server module and electrically connected with the server module. The signal transmission module is connected with the liquid level monitoring module, temperature monitoring module, pressure monitoring module, and leakage monitoring. The module and the gas monitoring module are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com