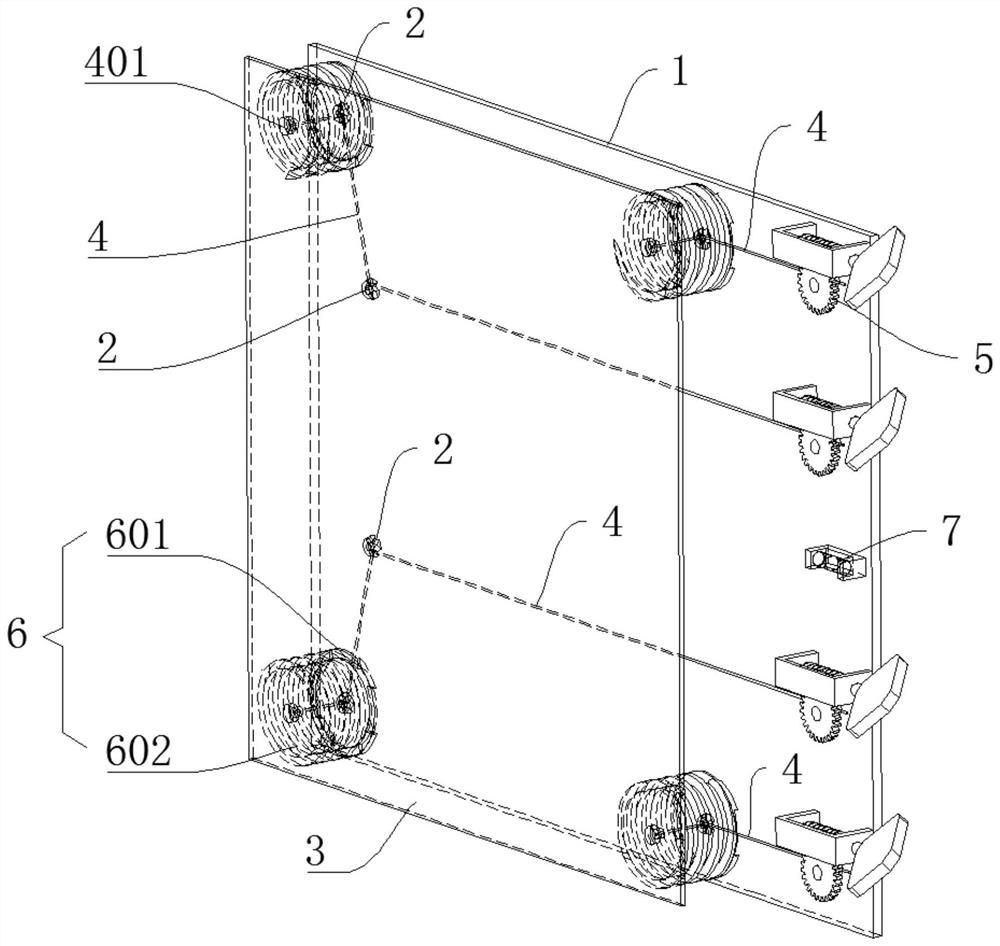

Longitudinal seam impaction device and longitudinal seam impaction resetting method

A reset method and longitudinal seam technology, which is applied in building maintenance, earthquake resistance, building components, etc., can solve the problems of poor impacting effect of longitudinal seam impaction devices, and achieve the effect of meeting earthquake resistance requirements and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

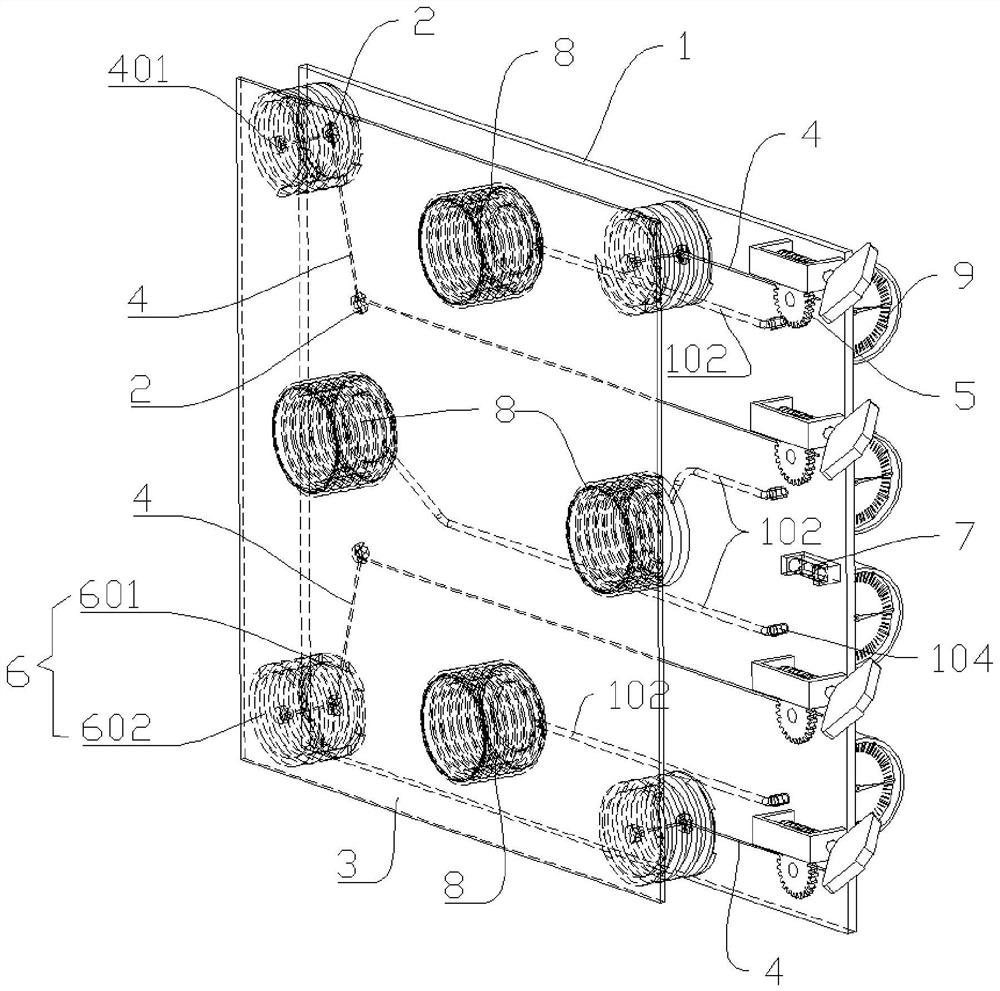

Embodiment 1

[0043] Gaps caused by manufacturing errors, installation process requirements, etc. are common in traditional and modern building structures, especially longitudinal gaps perpendicular to the ground, which widely exist in traditional building beam-column mortise and tenon joints and modern building prefabricated structures. Working with joints has become a common working state of structural components. During the long service period, the self-weight, earthquake load, etc. will increase the gaps; the impact of environmental factors on materials will also cause the gaps between the above-mentioned components to increase. If the gap is large, the connection of the components will be loosened, and the horizontal swing or even twist of the components will be caused during the earthquake, which is extremely detrimental to the earthquake resistance of the building. Although some longitudinal gaps can be reinforced or reinforced by adding caulking devices, similar devices have single f...

Embodiment 2

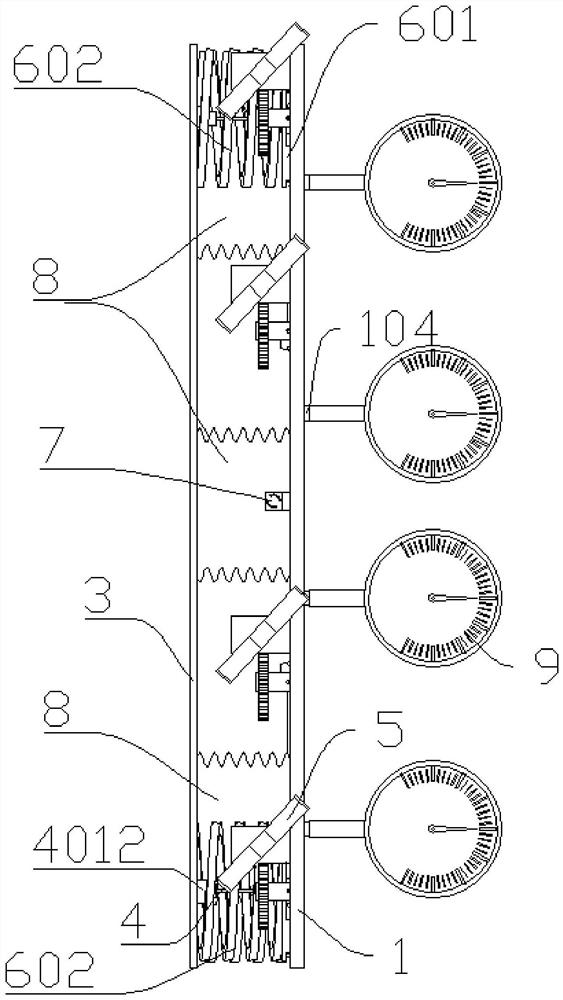

[0067] This embodiment provides a longitudinal seam impaction reset method, which is applied to the longitudinal seam impaction device provided in the above embodiment. The longitudinal seam impaction reset method includes:

[0068] S1. Operate the stranded wire retracting device 5 to tighten the stranded wire 4, so that the distance between the first dammed plate 1 and the second dammed plate 3 is reduced, and one side of the first dammed plate 1 is away from the second dammed plate 3 The distance between the side and the side of the second caulking panel 3 facing away from the first caulking panel 1 is smaller than the width of the longitudinal slot to be caulked. At this time, the first caulking plate 1 and the second caulking plate 3 can be easily caulked into the longitudinal seam. It should be noted that when the twisted wire retracting device 5 includes the above-mentioned rotating shaft 501 , worm gear 502 , bracket 503 , worm 504 and knob 505 , the twisted wire 4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com