Bacillus coagulans and application thereof in corn soaking

A Bacillus coagulans and corn soaking technology, applied in the direction of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high usage, long soaking time, high energy consumption, etc., and achieve reduced sulfur dioxide consumption and soaking effect Good, high starch yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This example is used to illustrate the isolation, purification and preservation of Bacillus coagulans CGMCC No. 23993 provided by the present invention.

[0052] (1) Strain isolation and purification

[0053] The inventor of the present invention isolated and obtained a strain of Bacillus coagulans CGMCC No.23993 from the corn soaking liquid used in the countercurrent soaking process in the corn starch production line of COFCO Biochemical Energy (Yum) Co., Ltd. The specific separation and purification process is as follows:

[0054] Corn steep liquor dry powder liquid medium is used as the enrichment medium, and its composition is: glucose 20g / L, beef extract 10g / L, peptone 10g / L, yeast extract 5g / L, triammonium citrate 2g / L, sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L, magnesium sulfate 0.2g / L, manganese sulfate 0.05g / L.

[0055] Take COFCO Biochemical Energy (Yumshu) Co., Ltd., 0.5mL of corn soaking solution from the countercurrent soaking process of c...

Embodiment 2

[0060] This example is used to illustrate the improvement of the corn soaking effect of Bacillus coagulans CGMCC No.23993 provided by the present invention.

[0061] Bacillus coagulans DUT21 was cultured with corn steep liquor dry powder medium, and the specific culture conditions included: 200rpm shaker culture at a temperature of 50±2°C for 24 hours to obtain DUT21 culture medium for use. After testing the OD of the DUT21 culture medium 600 The value is about 6.1±0.7 (equivalent to the effective number of viable bacteria of DUT21 is about 6.08×10 8 CFU / mL).

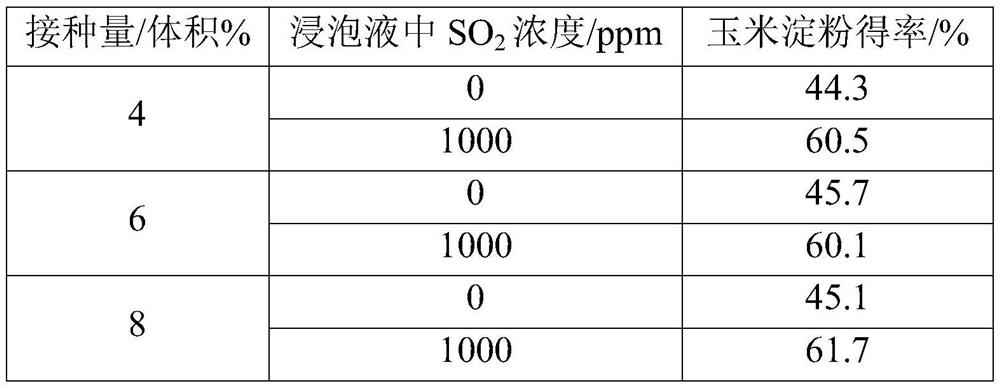

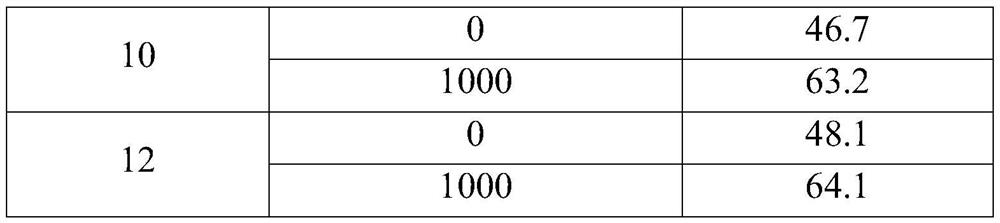

[0062] (1) Effect of Bacillus coagulans DUT21 inoculation amount on corn soaking effect

[0063] The inoculation amount of the DUT21 culture solution is 4 volume%, 6 volume%, 8 volume%, 10 volume%, 12 volume%, and the total volume is 150mL (remainder is filled with sterile water). A certain amount of SO was introduced into the soaking solution 2 , so that SO in the soaking solution 2 The concentration is 1000ppm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com