Single-component low-temperature crosslinking water-based paint and preparation method thereof

A water-based coating and low-temperature cross-linking technology, applied in the field of coatings, can solve the problems such as failure to achieve and difficult low-temperature curing of one-component water-based coatings, and achieve the effects of low VOC, ensuring construction applicability and good construction applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

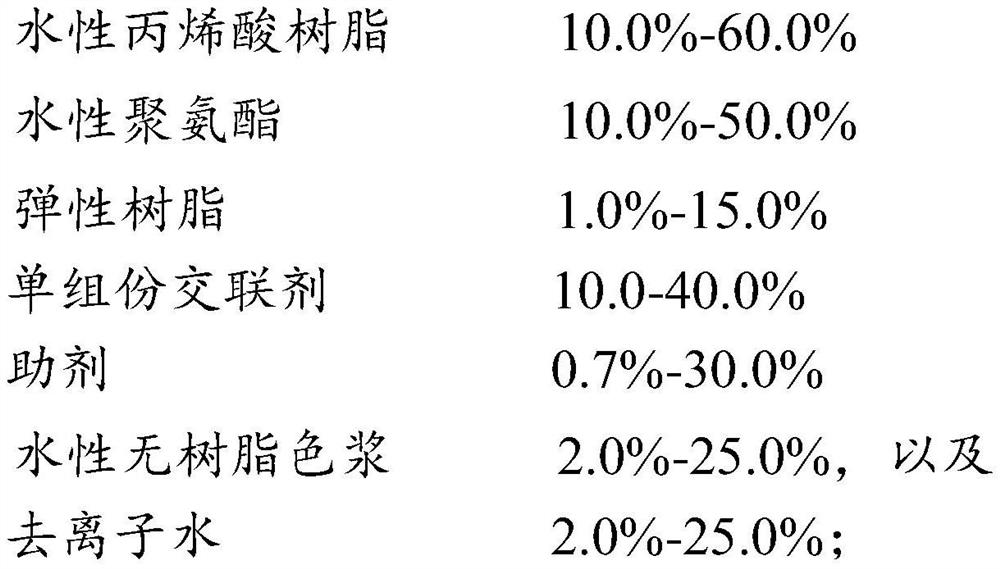

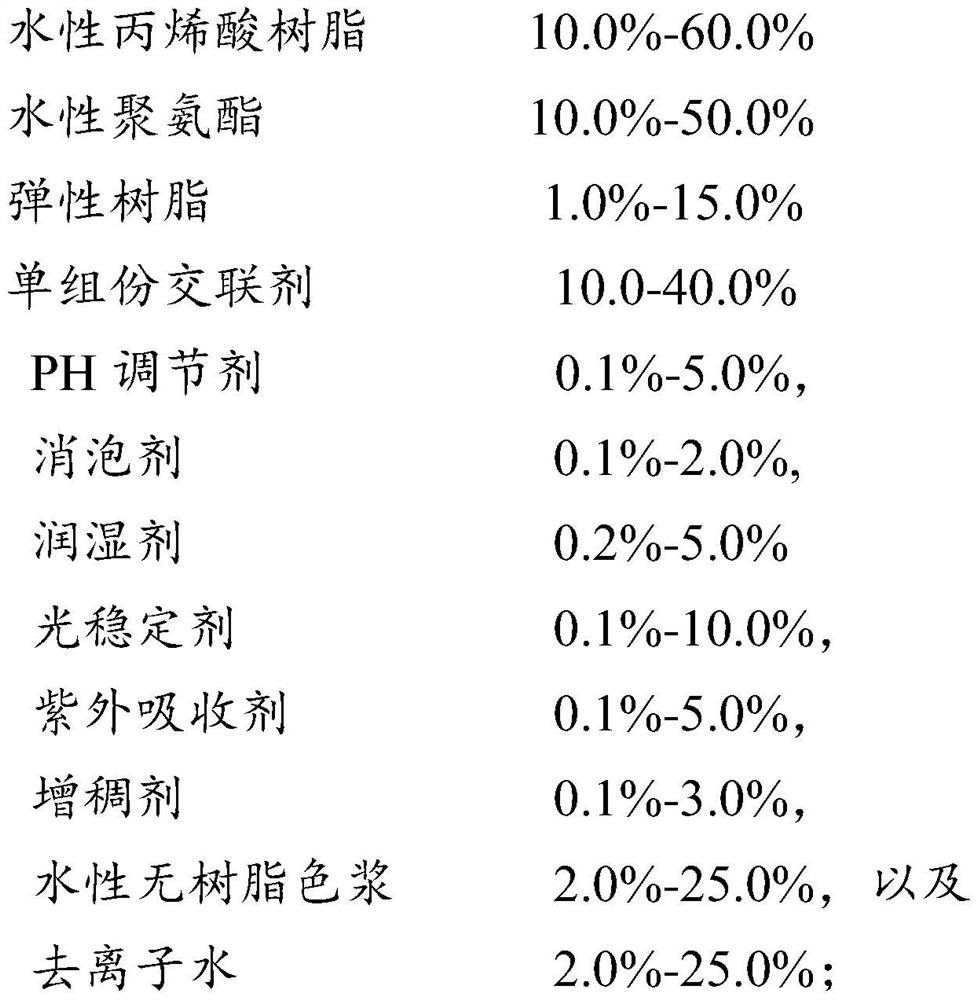

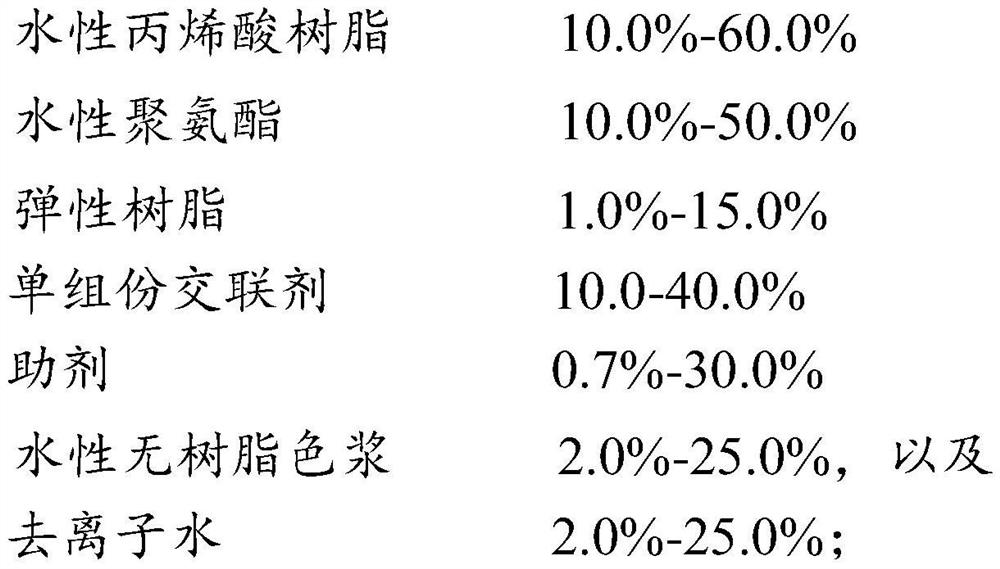

Method used

Image

Examples

example 1

[0067] The preparation of example 1 coating composition 1 (comparative example 1)

[0068] It should be noted that the coating composition 1 described in this example 1 does not have the one-component cross-linking agent described in the present invention, but uses the traditional high-temperature baking amino resin—Cymel 325 of Cytec Corporation of the United States as the cross-linking agent. Joint agent, so this coating composition 1 is only as comparative example 1.

[0069] This coating composition 1 is prepared by the following method:

[0070] (1) Under stirring, add 15.0g of water-based acrylic resin Joncryl 8312, 17.1g of water-based polyurethane resin Bayhydrol A 2750, 7.0g of water-based acrylic resin Antkote 2042, 1.5g of elastic resin KFlex-188, and a crosslinking agent in the reaction vessel Cymel 325 15g, PH regulator 10% DMEA 0.2g, defoamer Tego 805N 0.2g, defoamer Foamstar ST 2400 0.6g, wetting agent BYK-345 0.1g, and then use a high-speed disperser to dispe...

example 2

[0073] Preparation of Example 2 Coating Composition 2

[0074] Different from the coating composition 1 described in the above example 1, the coating composition 2 in this embodiment has the one-component crosslinking agent (hereinafter referred to as crosslinking agent BIT-50WB) prepared by the following method according to the present invention .

[0075] The above-mentioned cross-linking agent BIT-50WB is prepared by the following method:

[0076] (1) Mix 50 g of isocyanate HDI trimer, 18 g of cyclohexanone, 20 g of xylene, 25 g of butanone, and 0.3 g of DBTDL at 600 rpm for 5 minutes to generate an isocyanate solution;

[0077] (2) Heat the above-mentioned isocyanate solution to 45°C, and gradually add caprolactam as a blocking agent at a speed of 500 to 800 rpm, keeping the ratio of the hydroxyl group of the blocking agent to the NCO group of the isocyanate within the range of 1:1 to 3:1. After 2 hours of dripping, the temperature was slowly raised to 70-75°C after co...

example 3

[0086] The preparation of example 3 coating composition 3 (comparative example 2)

[0087]Different from the coating composition 1 described in the above example 1, the coating composition 3 in this example has the one-component crosslinking agent BIT-50WB described in the present invention. The crosslinker BIT-50WB was prepared by the method described in Example 2.

[0088] However, coating composition 3 in this example does not have the elastic resin described in the present invention. Therefore, this embodiment is only used as Comparative Example 2.

[0089] This coating composition 3 is prepared by the following method:

[0090] (1) Under stirring, add the above-mentioned water-based acrylic resin Joncryl 831215.0g, water-based polyurethane resin Bayhydrol A 2750 18.6g, water-based acrylic resin Antkote 2042 7.0g, cross-linking agent BIT-50WB 15g, pH regulator 10% DMEA 0.2g, defoamer Tego 805N 0.2g, defoamer Foamstar ST2400 0.6g, wetting agent BYK-345 0.1g, and then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com