Self-leveling mortar with later crack self-repairing function and preparation method thereof

A self-leveling mortar and self-healing technology, applied in the field of building materials, can solve the problems of very strict requirements on raw material varieties, specifications, dosage and matching, product performance decline, and large repair workload, etc. Adhesion, the effect of reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing self-leveling mortar with the function of self-repairing cracks in the later stage, the specific steps are as follows:

[0045] S1. Premix the modified blast furnace slag aggregate and composite additive B until uniformly mixed, and set aside;

[0046] S2. First put in the aggregate, filler and cementitious material accounting for half of the total amount, start the mixer, and mix at a stirring speed of 55r±5r / min;

[0047] S3, while stirring, slowly add composite additive A and redispersible latex powder to mix;

[0048] S4. Continue to add the mixture obtained in step S1 and the remaining half of the aggregate and filler, continue to stir at a stirring speed of 55r±5r / min, and stir for 3-5 minutes to obtain a self-leveling mortar with a self-repairing function for later cracks.

[0049]The invention uses anti-cracking double fast high belite sulfoaluminate cement and redispersible latex powder as the main bonding materials, together with 70-140...

Embodiment 1

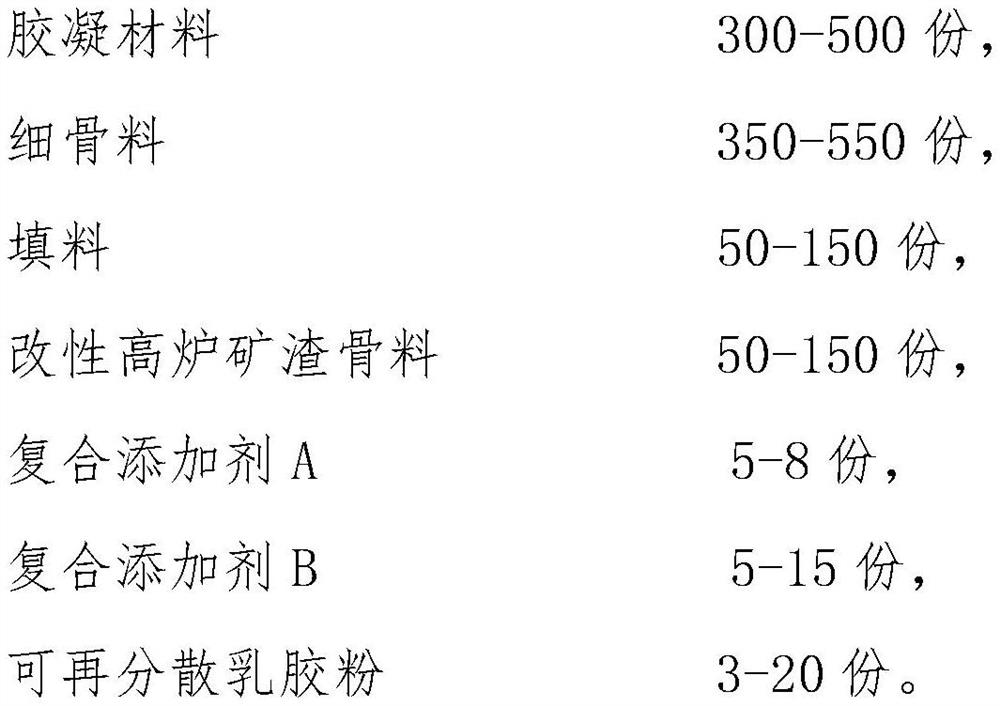

[0051] A self-leveling mortar with a self-repairing function for later cracks, mainly composed of the following raw materials combined in parts by weight:

[0052]

[0053] The preparation method of embodiment 1 comprises the following steps:

[0054] S1. Premix the modified slag aggregate and the composite additive B until uniformly mixed, and set aside;

[0055] S2. First put half of the total amount of 70-140 mesh washed sand, 400 mesh heavy calcium and all the anti-cracking double fast high belite sulfoaluminate cement, start the mixer (stirring speed is 55r±5r / min), to mix;

[0056] S3, while stirring (55r±5r / min), slowly add composite additive A and Wacker 5011L for mixing;

[0057] S4, continue to add step S1 to obtain the mixture and the remaining half of the washed sand and heavy calcium, and continue to stir (55r ± 5r / min) for 3-5 minutes;

[0058] That is, the self-leveling mortar with the self-repairing function of later cracks is obtained.

Embodiment 2

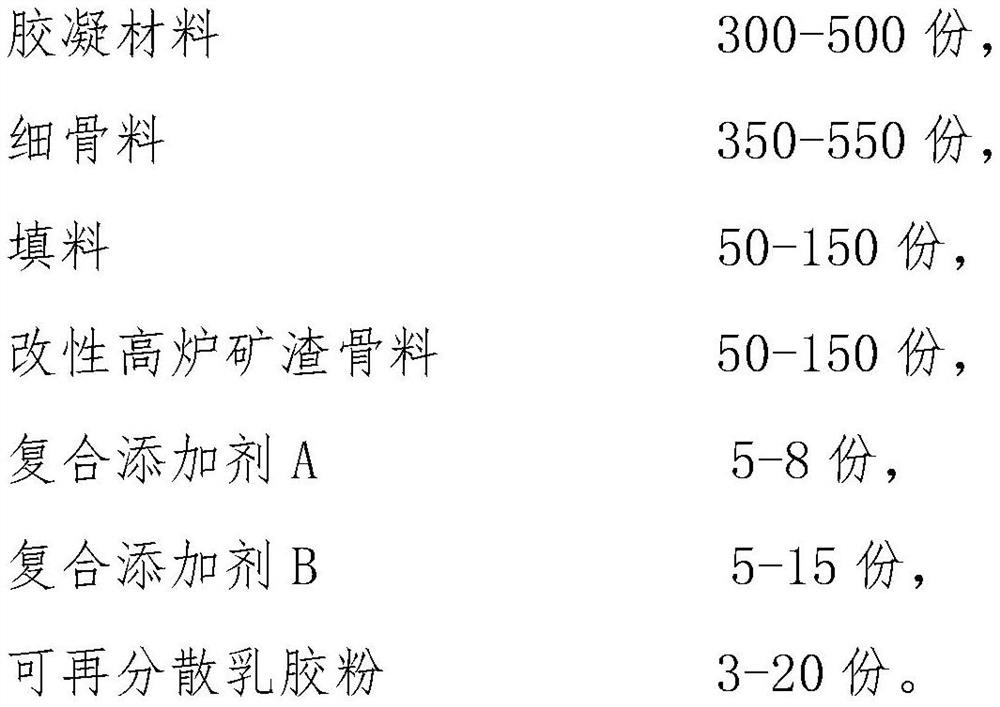

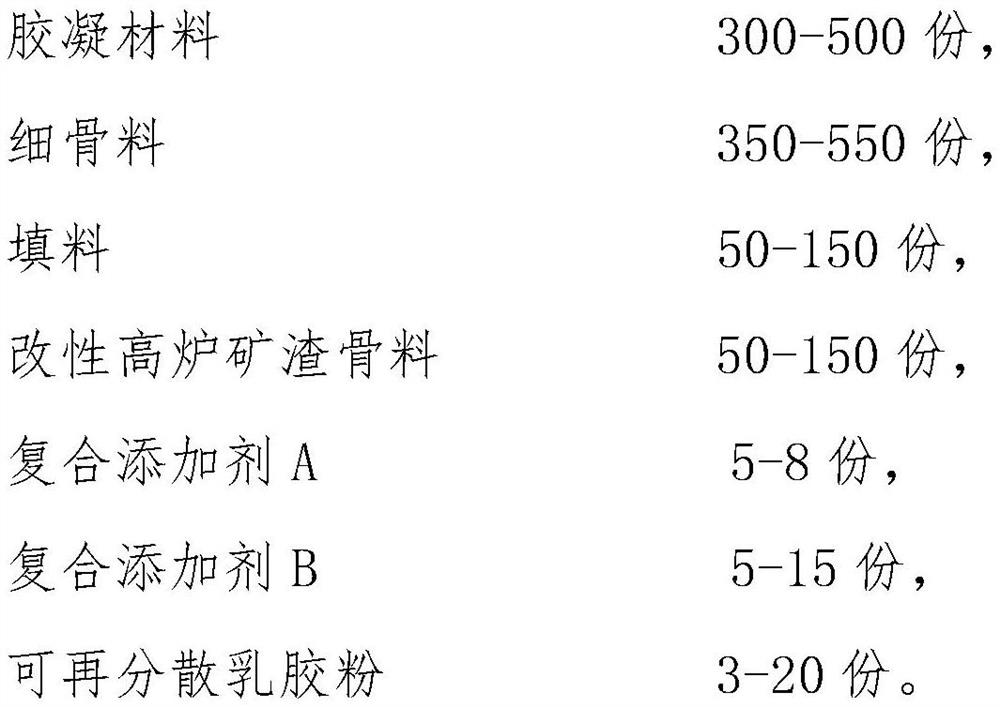

[0060] A self-leveling mortar with a self-repairing function for later cracks, mainly composed of the following raw materials combined in parts by weight:

[0061]

[0062]

[0063] The preparation method of embodiment 2 comprises the following steps:

[0064] S1. Premix the modified slag aggregate and the composite additive B until uniformly mixed, and set aside;

[0065] S2. First put half of the total amount of 70-140 mesh washed sand, 400 mesh heavy calcium and all the anti-cracking double fast high belite sulfoaluminate cement, start the mixer (stirring speed is 55r±5r / min), to mix;

[0066] S3, while stirring (55r±5r / min), slowly add composite additive A and Wacker 5011L for mixing;

[0067] S4, continue to add step S1 to obtain the mixture and the remaining half of the washed sand and heavy calcium, and continue to stir (55r ± 5r / min) for 3-5 minutes;

[0068] That is, the self-leveling mortar with the self-repairing function of later cracks is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com