Concrete processing equipment and production process thereof

A technology for processing equipment and concrete, applied in clay preparation devices, mixing operation control, mixing operation control devices, etc., can solve the problems of inability to crush gravel, low cement quality grade, etc., and achieve the effect of improving the quality grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

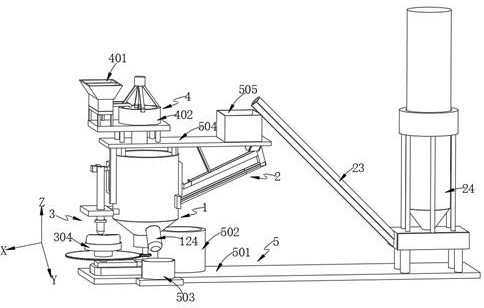

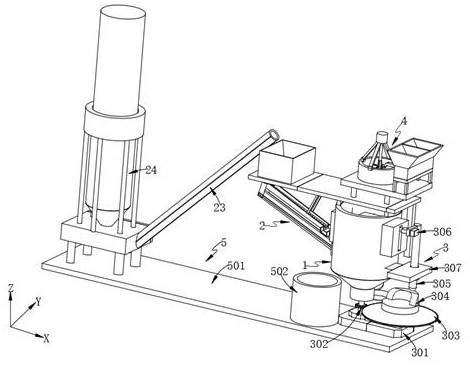

[0082] Such as Figure 1-2 As shown, a concrete processing equipment includes a body 5, and also includes:

[0083] The first mixing unit 1;

[0084] A gravel feeding unit 2, the gravel feeding unit 2 is arranged on the side of the first mixing unit 1;

[0085] A transmission unit 3, the transmission unit 3 is arranged on the side of the gravel feeding unit 2;

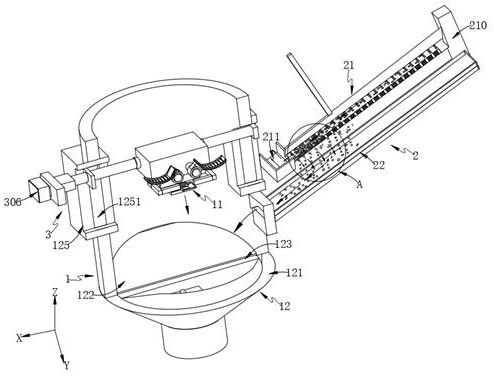

[0086] The first mixing unit 1 includes: an overturning crushing assembly 11 and a first stirring assembly 12;

[0087] The overturning and crushing assembly 11 is placed in the middle of the bottom of the first stirring assembly 12;

[0088] The gravel preliminarily screened by the gravel feeding unit 2 enters the first mixing assembly 12 for mixing with cement and sand, and when stirring, the first mixing assembly 12 synchronously drives the transmission unit 3 to reciprocate up and down, prompting the overturning and crushing assembly 11 to The gravel that does not meet the size entering the first mixing unit 1 ...

Embodiment 2

[0143] Such as Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0144] The present invention also provides a concrete production process, comprising the following steps:

[0145] S1. Weighing: After weighing the cement, sand and gravel in sequence according to the proportioning ratio, put the cement and sand into different storage areas corresponding to the cement sand storage box 401, and put the gravel into the gravel storage box 24;

[0146] S2. Preliminary mixing: put the weighed cement and sand in the cement and sand storage box 401 into the mixing tank 402 for preliminary mixing, and then put them into the first mixing unit 1;

[0147] S3. Adding gravel: the gravel scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com