Use method of new energy automobile plate shearing equipment

A new energy vehicle and shearing technology, which is applied in the direction of shearing equipment, metal processing equipment, shearing machine accessories, etc., can solve the problems of inability to guarantee the accuracy of shearing size, unstable cutting state, time-consuming and labor-intensive, etc., to achieve It is not easy to shift, the shearing process is stable, and the size is easy to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

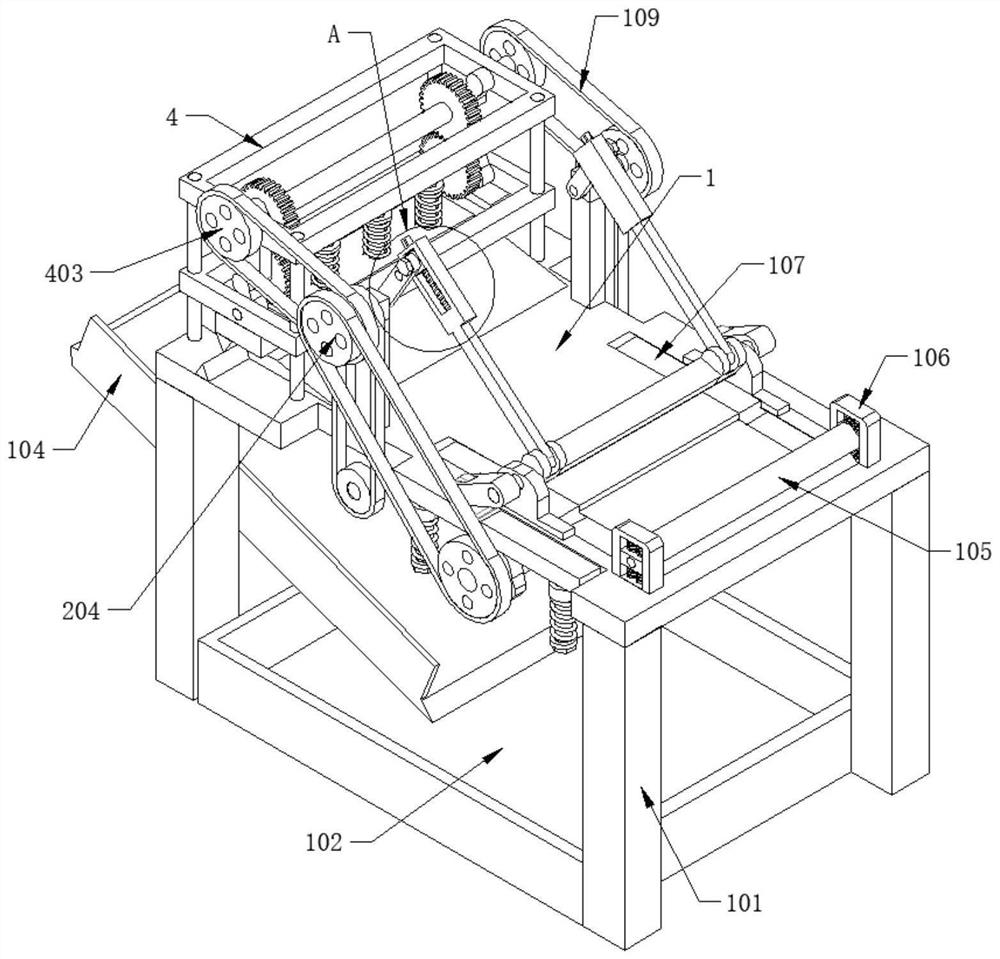

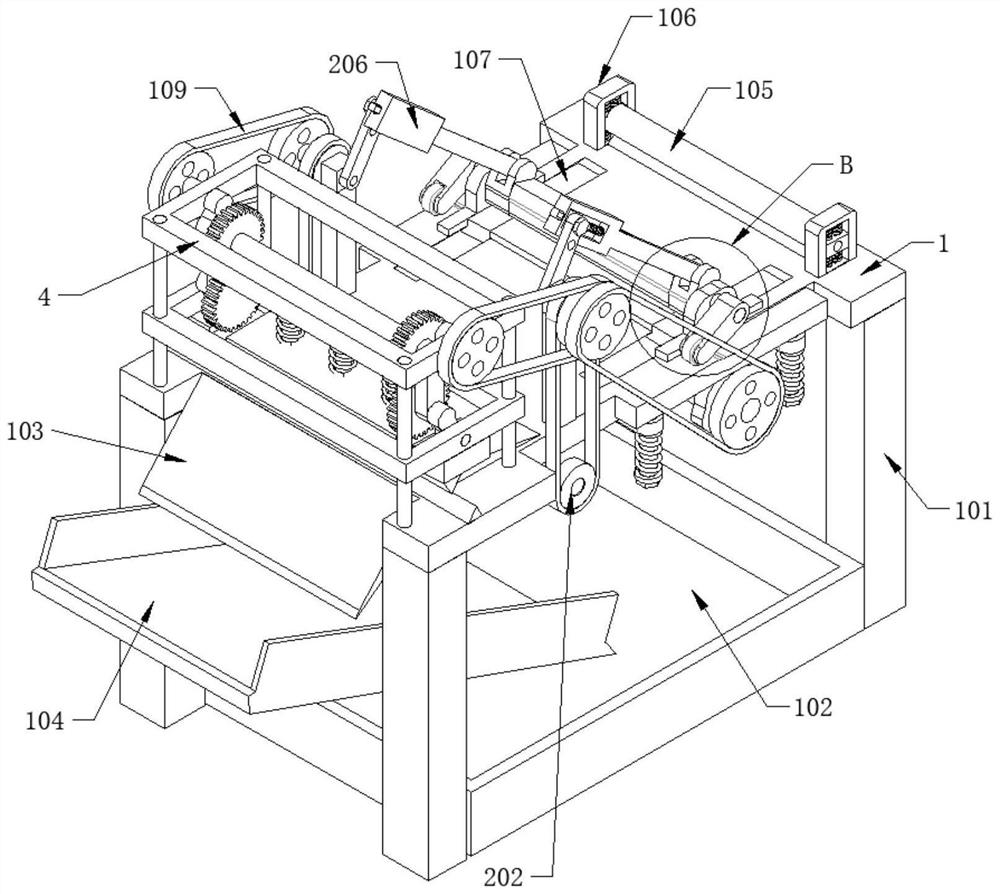

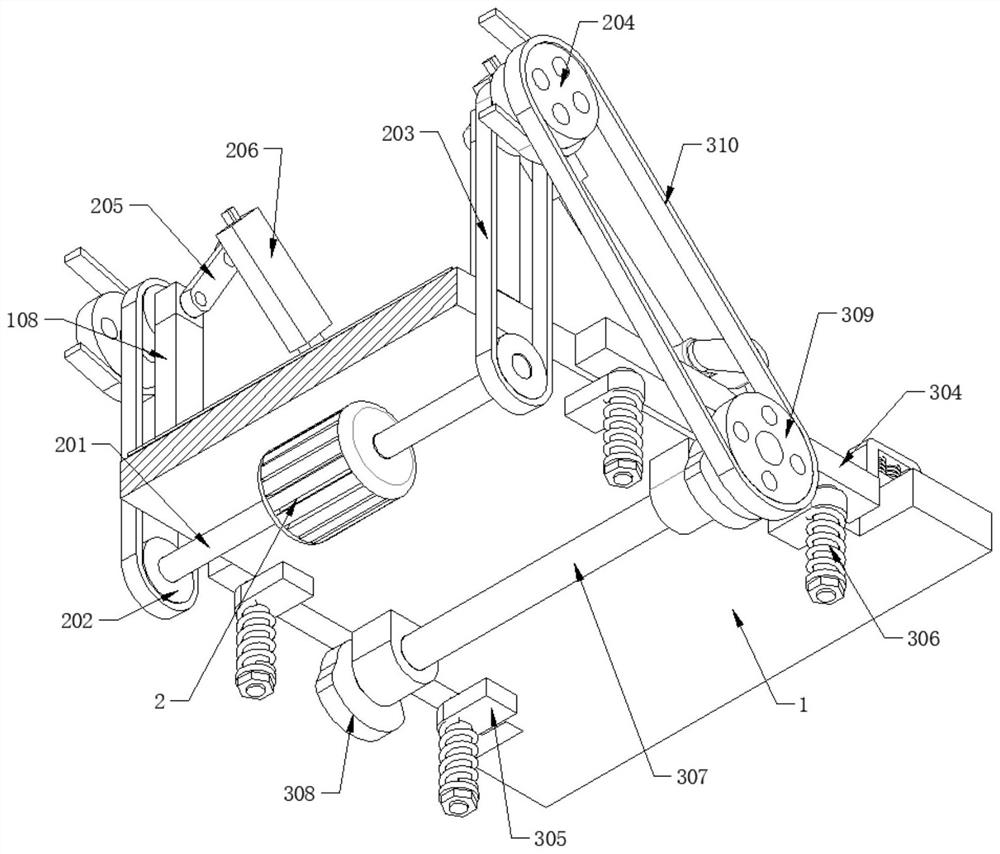

[0040] refer to Figure 1-9 , a kind of shearing equipment for the production of new energy auto parts, comprising a mounting table 1 and a supporting leg 101, the supporting leg 101 is connected to the bottom wall of the mounting table 1, and the top of the mounting table 1 is sequentially provided with a feeding assembly, a pushing mechanism and a shear Cutting mechanism, feed assembly and pusher mechanism match, pusher mechanism and shearing mechanism match, installation table 1 side wall is connected with first material receiving plate 103, support leg 101 inner wall is connected with second material receiving plate 104 and Collecting box 102, collecting box 102 cooperates with the second material receiving plate 104, the first material receiving plate 103 and the shearing mechanism successively, and the pushing mechanism includes double-headed motor 2, connecting rod assembly and pressing assembly, connecting rod The components are matched with the pressing components, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com