Construction method for connecting straight thread sleeves of main reinforcements of underground diaphragm wall

The technology of straight thread sleeve and underground diaphragm wall is applied in the direction of thread cutting auxiliary equipment, manufacturing tools, wire processing, etc., which can solve the problems of low technical level of construction personnel, poor control of construction process, and reduced quality of sleeve connection. Achieve the effect of improving joint processing quality, improving construction productivity efficiency, and avoiding electric welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

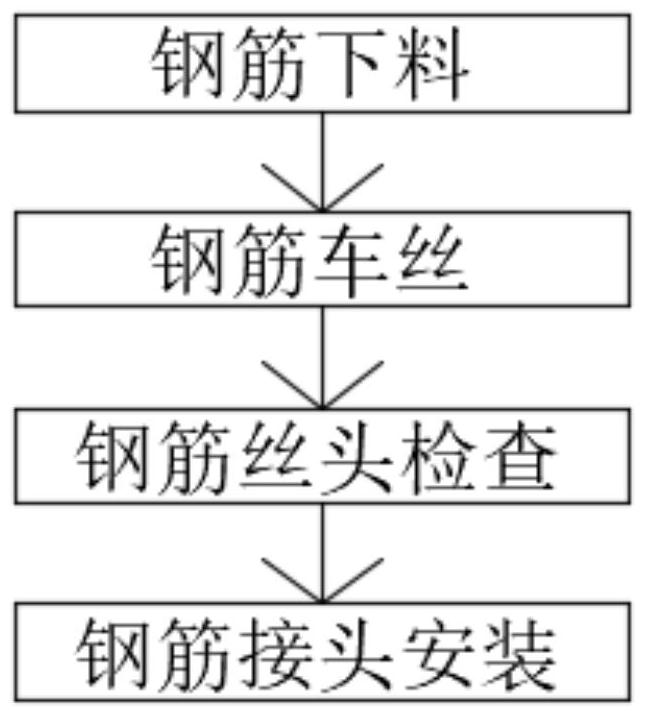

[0045] see figure 1 , a construction method for the straight thread sleeve connection of the main reinforcement of the underground diaphragm wall, comprising the following steps

[0046] Step 1. Rebar blanking. According to the construction requirements, select and use the corresponding specifications of the rebar, and cut the rebar into the corresponding length according to the required length;

[0047] Step 2, steel wire turning, using a wire wheel to process the two ends of the steel bar to be processed;

[0048] Step 3: Inspection of the steel bar head, check the appearance of the steel bar, the length of the wire head and the thread diameter;

[0049] Step 4: The steel bar joint is installed, using a straight threaded sleeve to connect the wire heads of the two steel bars.

[0050] In the embodiment of the present invention, in the first step, check the steel bars for blanking in advance, and straighten the bent ones to avoid affecting the quality of the incision. The s...

Embodiment 2

[0077] A construction method for connecting the main reinforcement of the underground diaphragm wall with a straight thread sleeve, a main project of the PZH-2 standard three work area of the Pearl River Delta intercity rail Pazhou branch line in Guangdong Province as an example, the full length of the PZH-2 standard three work area of the Pearl River Delta intercity Pazhou branch line 4.047km, the line crosses Mingjing Village, Yuexi Village, Tanshan Village, and Jiaotang Village in Panyu District, Guangzhou City. The main project includes 1 vertical shaft, 3 evacuation shafts, 5897.36m shield tunnel (2640m on the left line, 3257.36m on the right line), 1280m open cut tunnel (850m on the left line, 430m on the right line), and 246.8m (51.39m+ 195.41m), and one continuous rigid frame bridge (93.2m). Among them, the open-cut tunnels are all constructed by open-cut method, and the foundation pit enclosure mainly adopts the structural form of underground diaphragm wall plus r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com