Hydraulic machine and method for continuous punching

A hydraulic press and hydraulic technology, applied in the field of hydraulic presses, can solve the problems of manual removal of molded parts, inability to directly discharge, and increase operating pressure, and achieve the effect of reducing intermittent consumption time, facilitating continuous hydraulic processing, and reducing operating pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

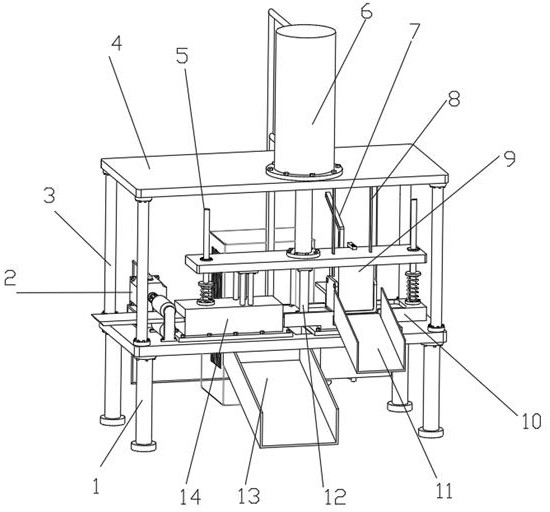

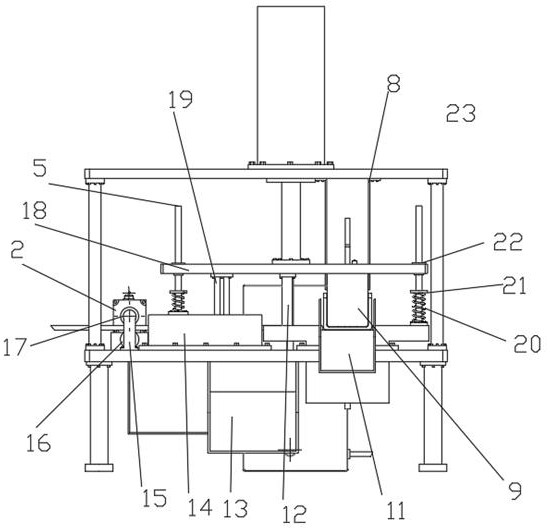

[0042] Such as Figure 1-7 As shown, the hydraulic press for continuous stamping includes a frame 1 and a control cabinet 24. A fixed-length hydraulic stamping assembly is arranged on the top of the frame 1. The fixed-length hydraulic stamping assembly is electrically connected to the control cabinet 24. The hydraulic stamping assembly performs fixed-length delivery of raw materials, Punch forming, end cutting and stamping;

[0043] The fixed-length hydraulic stamping assembly includes a height adjustment assembly, a fixed-length drive assembly, a punching assembly, an end cutting assembly, and a hydroforming assembly, and the punching assembly, the end cutting assembly, and the hydroforming assembly are connected to the height adjustment assembly;

[0044] The height adjustment assembly includes a support rod 3, a top plate 4, a hydraulic press 6 and a connecting plate 18. The support rod 3 is installed on the top of the frame 1, the top of the support bar 3 is fixed with a t...

Embodiment 2

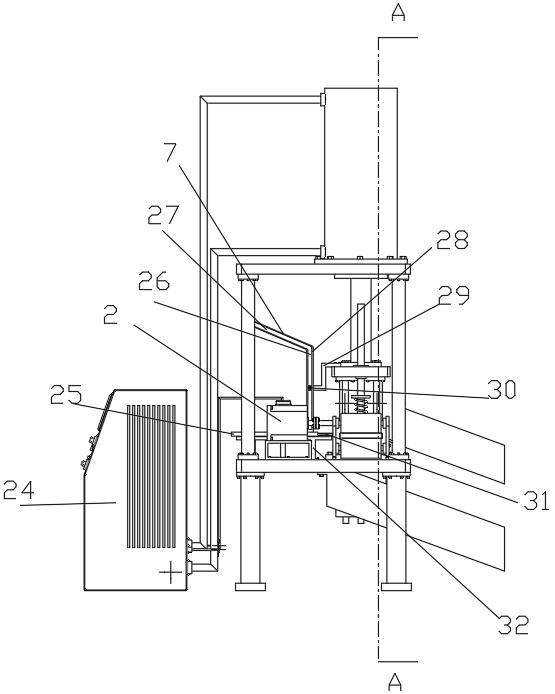

[0061] On the basis of embodiment 1, see Figure 3-7 As shown, the rear side wall of the fixed-length hydraulic stamping assembly is provided with a discharge assembly. The discharge assembly includes a reciprocating drive assembly, a pusher assembly, and a jacking assembly. The reciprocating drive assembly is connected to the pusher assembly. The components are connected, the pusher component and the jacking component are connected with the reciprocating drive component, the jacking component lifts the formed parts in the fixed-length hydraulic stamping component, the fixed-length hydraulic stamping component drives the reciprocating drive component to move back and forth, and the reciprocating drive component drives the pushing The material assembly moves back and forth to realize the ejection of molded parts.

[0062] The reciprocating drive assembly comprises a slant plate 7, a straight groove 26, a chute 27, a straight fixed plate 28, a connection block 29 and a push bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com