Combined inhibitor for separating pyrite from complex molybdenite and separation method thereof

A technology combining inhibitors and separation methods, applied in solid separation, flotation, etc., can solve problems such as unfavorable wood indicators, corrosion equipment, resource waste of molybdenite, etc., achieve good selectivity and inhibition ability, and improve comprehensive utilization Spatial, efficient separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention separates molybdenite and pyrite from the No. 1 Mineral Processing Plant of Jinduicheng Molybdenum Industry Ruyang Co., Ltd. The -200 mesh in the raw ore accounts for about 53%, of which the grade of molybdenum in the raw ore is about 0.115%, and the grade of Fe is about 4.83%. , the chemical residues on the mineral surface of the selected section make the separation more difficult.

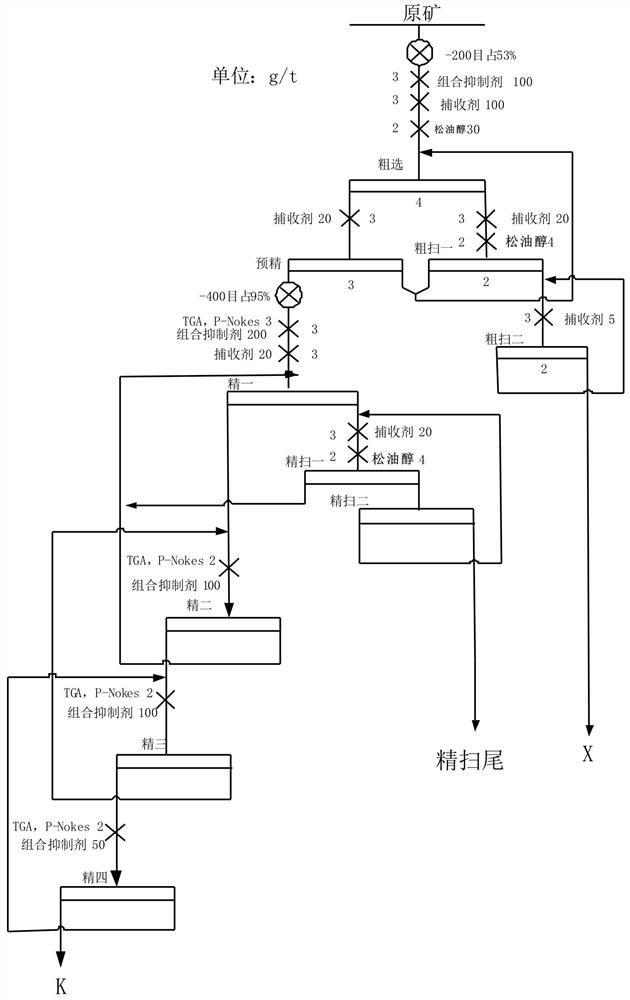

[0034] Grind the raw molybdenite to obtain pulp with a fineness of -200 mesh accounting for 53%. Add 100g / t combined inhibitor, 100g / t collector kerosene and 30g / t starting The foaming agent terpineol is used for stirring; during the selection, the pre-selected concentrate is ground to obtain a pulp with a fineness of -400 mesh accounting for 95%; the obtained pre-selected concentrate is subjected to four selections and two In the second fine sweeping process, combined inhibitors need to be added for stirring in each refining process. In the first refining process, i...

Embodiment 2

[0061] The present invention is used to separate molybdenite and pyrite from the No. 1 Mineral Processing Plant of Jinduicheng Molybdenum Industry Ruyang Co., Ltd. The -200 mesh in the raw ore accounts for about 53%, of which the molybdenum grade in the raw ore is about 0.121%, and the Fe grade in the raw ore is about 4.96%.

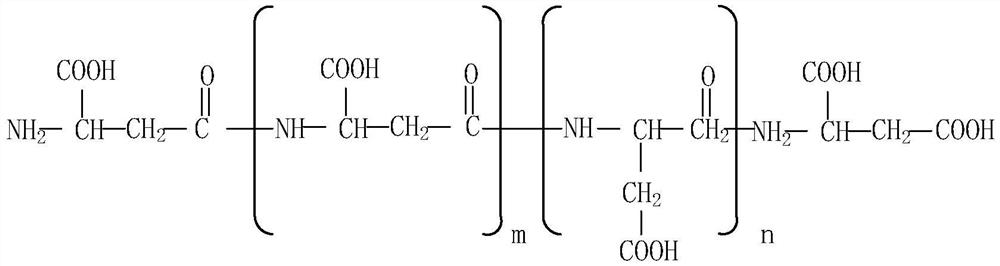

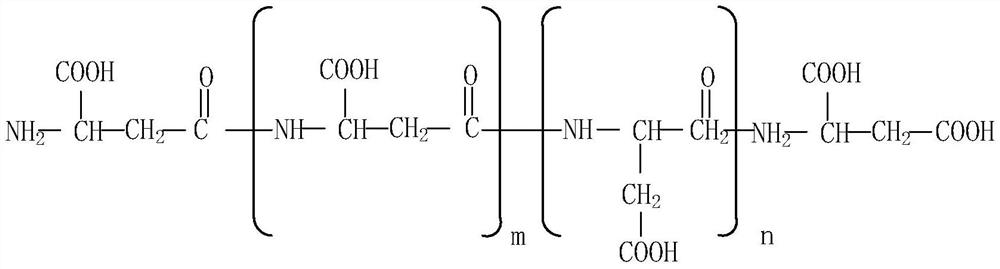

[0062] Grinding and flotation steps are the same as in Example 1, and the combined depressant consists of 1.0wt% polyaspartic acid aqueous solution, 6.0wt% calcium hypochlorite aqueous solution, and 6.0wt% sodium humate aqueous solution in a mass ratio of 3:1:1 mixed; adding 100g / t of combined inhibitors in the examples refers to adding 100g of combined inhibitors to 1 ton of raw ore; as shown in Table 1 below, the final Fe grade is 3.25 %, the recovery rate is 0.14%, the Mo grade is 47.13%, and the recovery rate is the final molybdenum concentrate of 85.49%.

[0063] The test result of table 6 flotation separation

[0064]

Embodiment 3

[0066] The present invention is used to separate molybdenite and pyrite from the No. 1 Mineral Processing Plant of Jinduicheng Molybdenum Industry Ruyang Co., Ltd. The -200 mesh in the raw ore accounts for about 53%, of which the molybdenum grade in the raw ore is about 0.115%, and the Fe grade in the raw ore is about 4.89%.

[0067] Grinding and flotation steps are the same as in Example 1, and the combined depressant consists of 0.7wt% polyaspartic acid aqueous solution, 5.0wt% calcium hypochlorite aqueous solution, and 4.0wt% sodium humate aqueous solution in a mass ratio of 3:1:1 mixed; adding 100g / t of combined inhibitors in the examples refers to adding 100g of combined inhibitors to 1 ton of raw ore; as shown in Table 7 below, the final Fe grade is 3.74 %, the recovery rate is 0.16%, the Mo grade is 46.98%, and the recovery rate is the final molybdenum concentrate of 85.50%.

[0068] The test result of table 7 flotation separation

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com