Uniform material distributing and screening system in ore grinding process

A technology of uniform material distribution and ore grinding, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve the problems of unfavorable economic and technical indicators of mineral processing, the effective screening area of linear vibrating screen becomes smaller, and the cycle load of ball mill becomes larger. , to achieve the effect of improving economic and technical indicators of beneficiation, improving resource recycling rate, and reducing waste and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

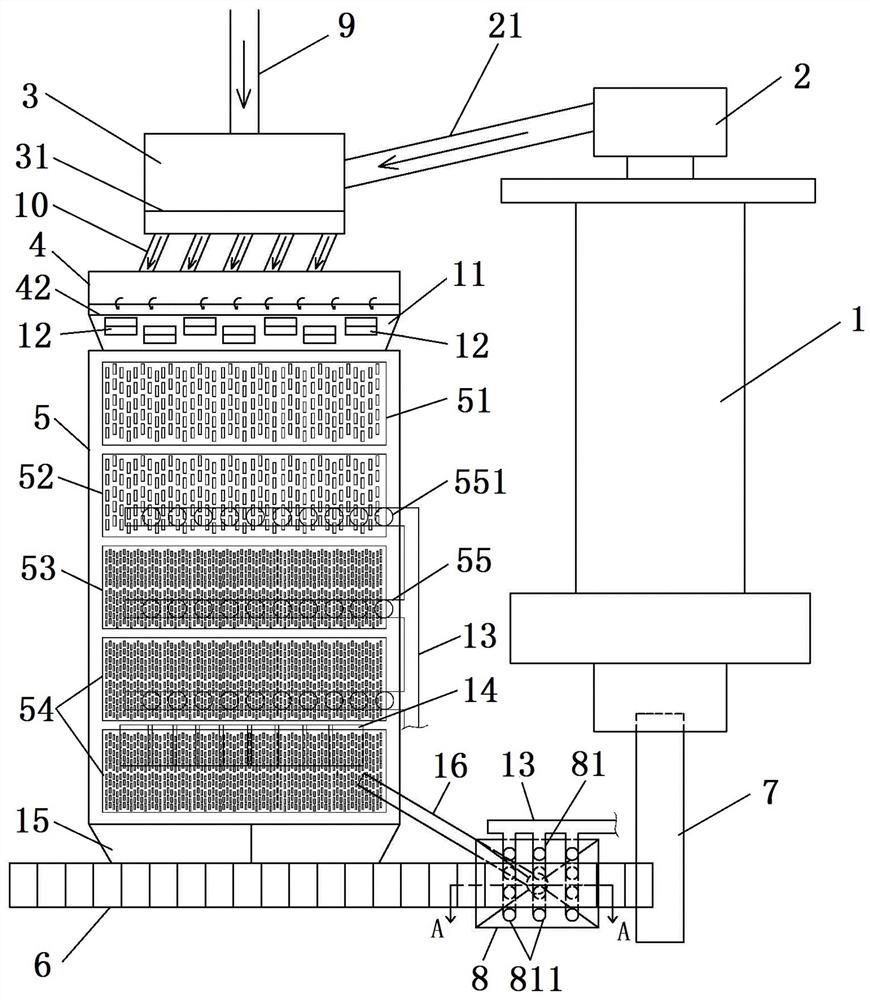

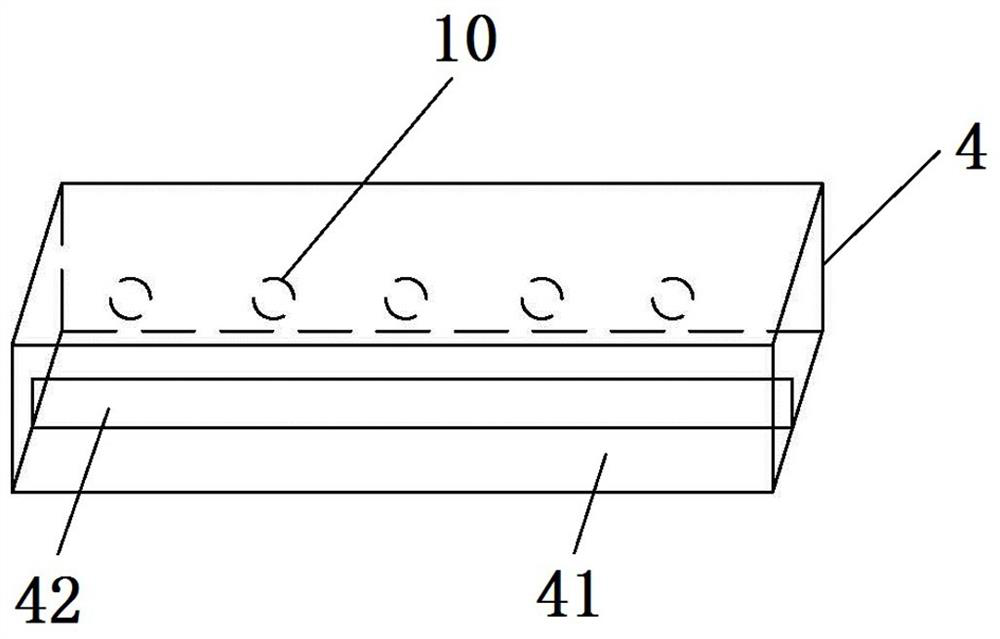

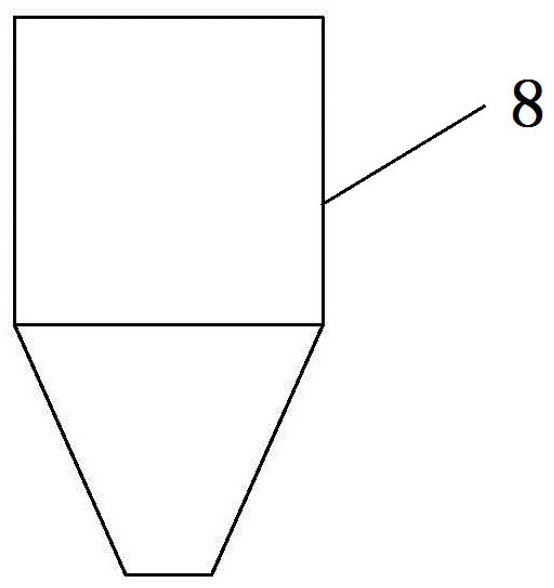

[0016] see figure 1 , the present invention is a uniform distribution and screening system in the ore grinding process, which includes a second-stage ball mill 1, an ore discharge chute 2, a buffer box 3, a uniform distribution box 4, a double-layer linear vibrating screen 5, and a large-inclination belt conveyor 6 , ball mill feeding chute 7 and collection bucket 8, wherein:

[0017] The discharge end of the second-stage ball mill 1 is provided with an ore discharge chute 2, and in this embodiment, the ore discharge chute 2 is a rectangle of 0.5×0.3m.

[0018] The top of the ore discharge chute 2 is equipped with a movable cover plate (not shown in the figure). The discharge end of the ore discharge chute 2 is connected, the discharge end of the second ball mill discharge pipe 21 is located near the bottom of the buffer box 3, and the bottom of the feed end of the second ball mill discharge pipe 21 is higher than its discharge end, so that the second-stage grinding pulp dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com