Extracting solution dehydration device for processing ginkgo biloba extract

The technology of a ginkgo extract and a dehydration device is applied in the directions of cleaning hollow objects, cleaning methods and utensils, separation methods, etc., and can solve the problems such as the inability of secondary rapid air-drying of dehydrated essence, the contamination of dehydrated essence ginkgo crystals, and the inability to achieve high-pressure evaporation, etc. Achieve the effect of improving the water pushing effect, fast dehydration efficiency, and rapid pressure release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

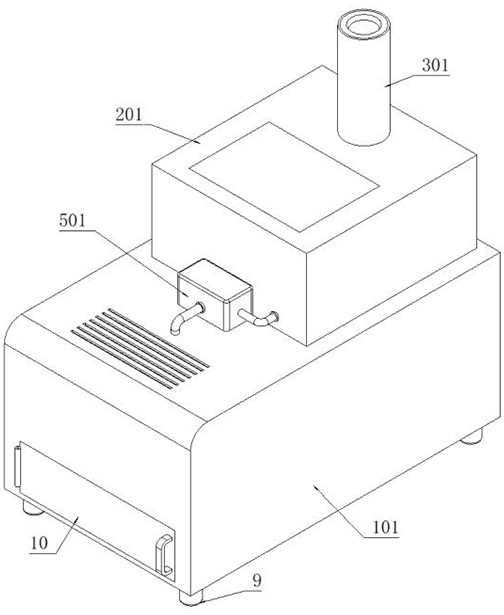

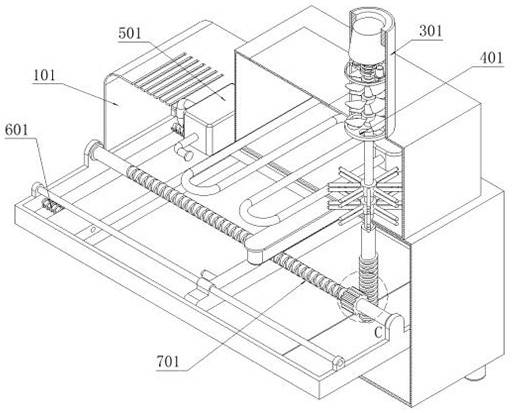

[0049] as attached figure 1 to attach Figure 15 As shown: the present invention provides an extraction liquid dehydration device for ginkgo extract processing, including a housing device 1; the four corners of the bottom of the housing device 1 are fixedly connected with non-slip feet 9; the front side of the housing device 1 is hinged with a sealed door 10. An evaporator 2 is fixedly connected to the housing device 1, and a pressure relief device 3 is installed on the evaporation device 2; a driving part 4 is installed on the pressure relief device 3; a flow guide part 5 is installed on the housing device 1; The inside of the body device 1 is fixedly connected with a blocking device 6; the inside of the shell device 1 is equipped with a decrystallization part 7; the driving part 4 includes: a driving bracket 401, and the driving bracket 401 is fixedly connected to the pressure relief installation cylinder 301 on the pressure relief device 3 Above; the steam blade group 402,...

Embodiment 2

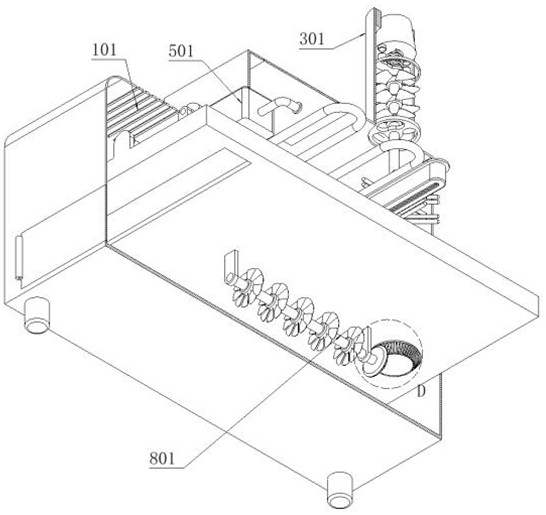

[0053] as attached Figure 9 , Figure 12 , Figure 13 , Figure 14 , Figure 15 As shown, the driving part 4 also includes: a threaded rod 404, which is fixedly connected to the bottom of the steam blade group 402; a driving bevel tooth 405, which is fixedly connected to the bottom of the threaded rod 404; the decrystallization part 7 includes : lead screw 701, lead screw 701 is connected on the support plate 102 through the rotation of the bracket; lead screw 701 is provided with a gear and meshed with the threaded rod 404; scraper 702, scraper 702 is slidably connected to the support plate through two sliding shafts 102, and the scraper 702 is threadedly connected to the lead screw 701; there are two extrusion blocks 703, two extrusion blocks 703, and the two extrusion blocks 703 are fixedly connected to the scraper 702; the cooling part 8 includes: cooling blade group 801 , the cooling blade group 801 is connected to the bottom of the support plate 102 through the rota...

Embodiment 3

[0055] On the basis of the first embodiment, other structures remain unchanged. This embodiment provides another structural form of the sealing block 306 to solve the problem of poor sealing of the sealing block 306 and greater wear and tear during long-term use, which affects the effect of pressurized evaporation. problem, the pressure relief device 3 includes: a pressure relief installation cylinder 301, the pressure relief installation cylinder 301 is fixedly connected to the installation shell 101; a snap ring 302, the snap ring 302 is fixedly connected to the pressure relief installation cylinder 301; a pressure relief bracket 303 , the pressure relief bracket 303 is fixedly connected inside the pressure relief installation cylinder 301; the pressure relief device 3 also includes: a sealing shaft 304, the sealing shaft 304 is fixedly connected on the pressure relief bracket 303, and a spring is set on the sealing shaft 304; the electromagnet 305 , there are two electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com