Cleaning scraping strip with water passing structure

A technology of scraping strips and passing water, which is applied to manual floor scrubbing machines, carpet cleaning, and household appliances. It can solve problems such as water absorption failure and blockage of scrapers, reduce negative pressure loss, prolong service life, and increase depth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

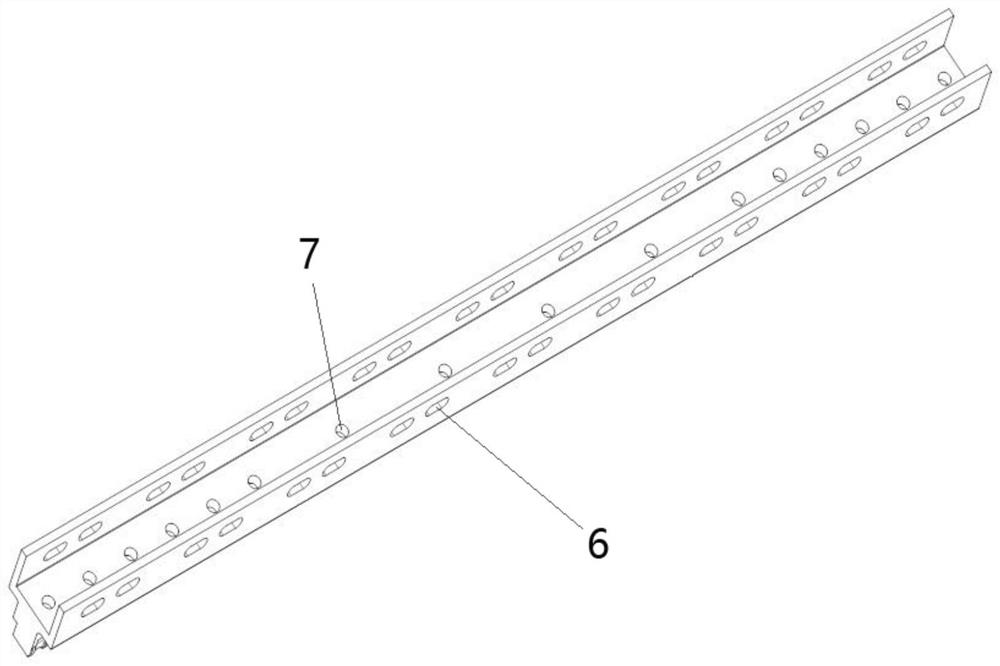

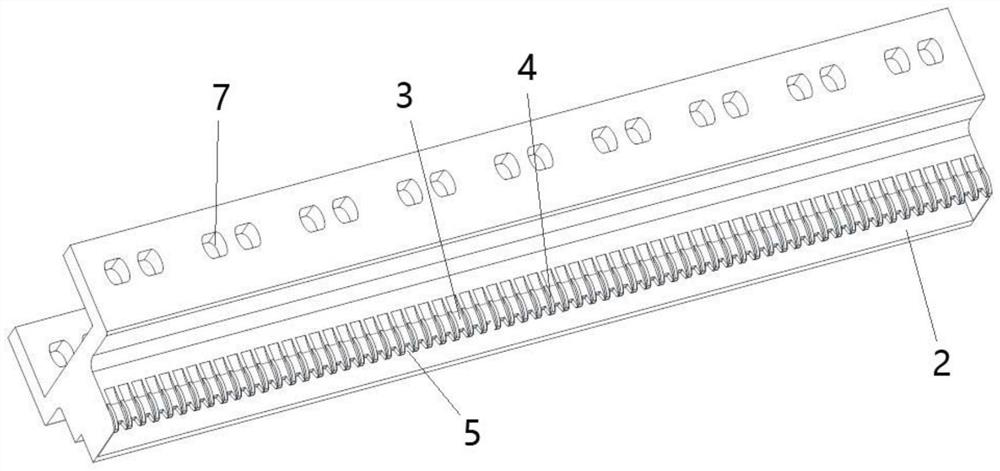

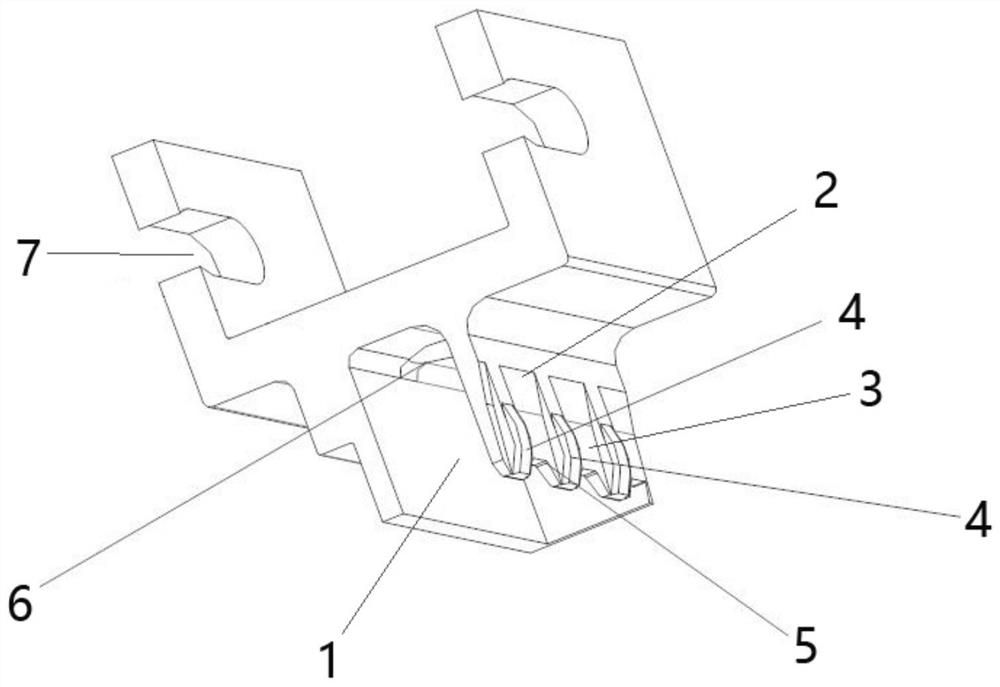

[0029] The first embodiment: as Figure 1-5 Show,

[0030] A cleaning scraper with a water-through structure in this embodiment includes a dirt collecting device with a dirt collecting tank 1 at the bottom. Sewage suction assembly, wherein: the front side of the scraper 2 is provided with a dirt collection channel 3, when the scraper 2 is pushed forward, the lower end of the scraper 2 bends backwards, and the dirt collection channel 3 is just located at the lower end of the curved scraper 2, The space in front of the dirt collection tank 1 and the scraper 2 is connected. It should be noted that since there is only one scraper 2 in this embodiment, the advancing direction of the cleaning scraper is defined here as front, not front and back in an absolute sense of space.

[0031] In the embodiment, the dirt collecting channel 3 is a vertical groove structure.

[0032] In the embodiment, the scraper 2 is provided with protruding scraper ribs 4 on the left and right sides of th...

no. 2 example

[0041] In the embodiment, both the front side and the rear side of the dirt collection tank 1 are composed of scraping strips 2, and the scraping strips 2 on the rear side have the same structure as the scraping strips 2 on the front side, and are arranged symmetrically.

[0042] The parts not described are the same as the first embodiment.

[0043] The scraper 2 is made of a flexible material, preferably rubber. When the cleaning scraper is pressed against the ground, the front and rear scraper 2 are bent and deformed backwards under force, which can cause the flow guide channels 5 of the front and rear scraper 2 to be closed. The dirt collection channel 3 of the scraper 2 will not move to the bottom of the rear scraper 2, and the rear scraper 2 is in a sealed state, while the dirt collection channel 3 of the front scraper 2 just moves to the bottom of the front scraper 2. At this time, The sewage collection channel 3, the sewage collection tank 1 and the water-air guide outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com