Motor base with functions of sound insulation, convenient fixation and tensioning of driving chain

A motor base and chain tensioning technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems that the convenience and accuracy of the motor cannot be guaranteed, and achieve the effect of ensuring convenience and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

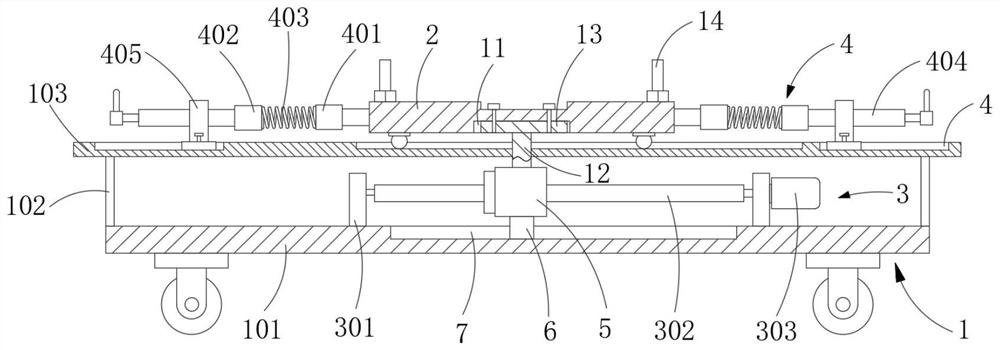

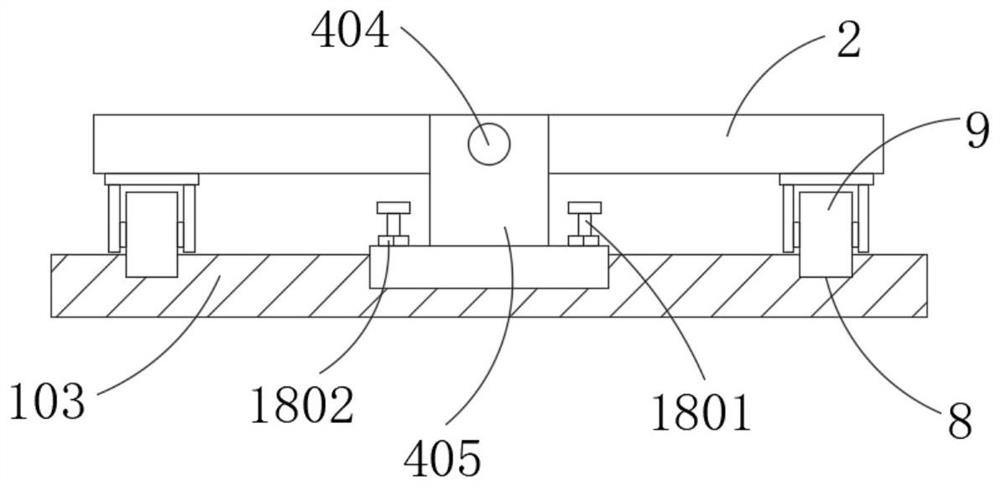

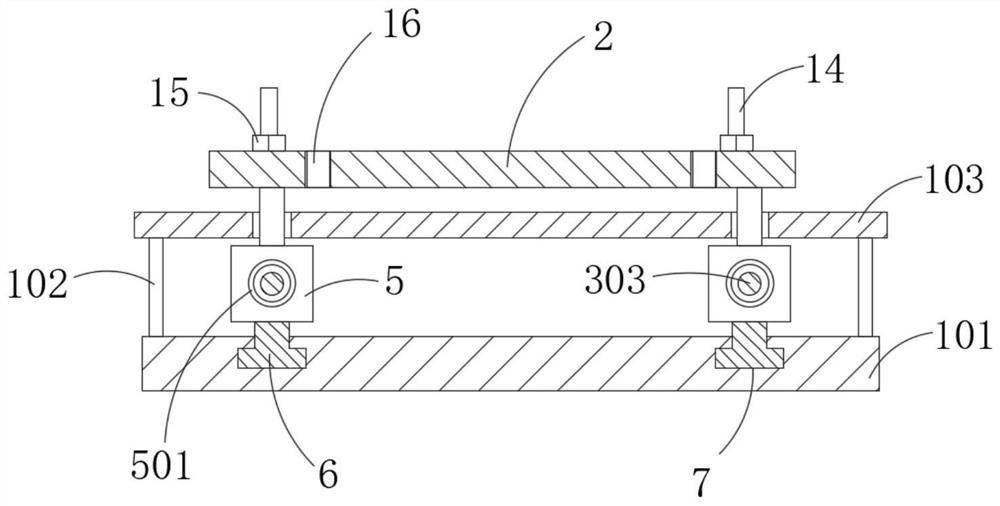

[0032] The present invention provides such Figure 1-6 The motor base with sound insulation, convenient and fixed drive chain tensioning function shown includes a mobile bottom bracket 1 and a motor mounting plate 2. The mobile bottom bracket 1 includes a bottom plate 101 and a column 102, and the column 102 is fixedly installed on the bottom plate. 101 upper surface, the top of the column 102 is fixedly installed with a support plate 103, the motor mounting plate 2 is slidably installed on the upper surface of the support plate 103, the upper surface of the support plate 103 is provided with a chute 8, and the motor mounting plate 2 A rubber pulley 9 is fixedly installed on the bottom surface, and the rubber pulley 9 is slidably installed in the chute 8. A rubber pulley 9 is arranged on the bottom surface of the motor mounting plate 2. After the motor is installed on the motor mounting plate 2, the drive assembly 3 at the bottom is used to control the motor The mounting plate...

Embodiment 2

[0038] Between the bottom plate 101 and the support plate 103 and outside the four sets of columns 102, organ covers are arranged in sequence. Because the screw drive motor 303 is arranged in the moving bottom bracket 1, in order to ensure the effect of sound insulation and noise reduction, an organ cover is provided to simplify the structure; At the same time, a self-locking universal wheel is arranged on the bottom surface of the base plate 101 to facilitate the movement of the whole mechanism and to cooperate with the assembly at any position of the production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com