Subsystem fluctuation signal analysis method based on causal analysis

A signal analysis method and causal analysis technology, which is applied in the field of industrial control system fault diagnosis, can solve problems such as modal aliasing, and achieve the effects of easy operation, simple algorithm principle, and improved accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

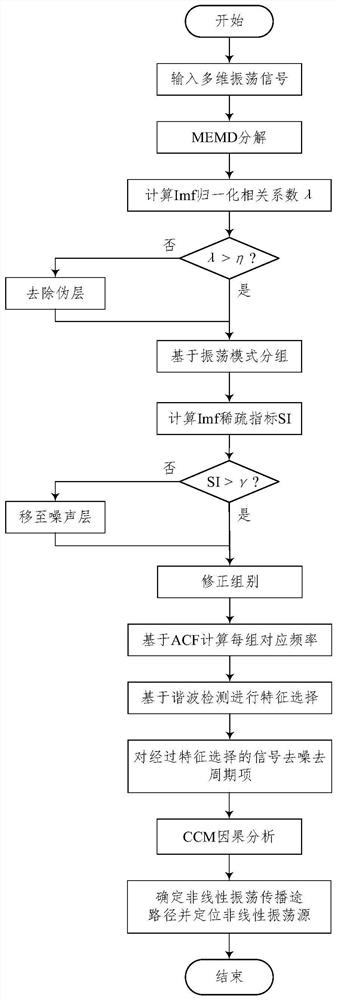

Method used

Image

Examples

Embodiment Construction

[0101] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

[0102] Taking the hydrogen conversion of an oil refinery in Southeast Asia as an example, the causal analysis-based correlative subsystem control fluctuation correlation modeling technology for a chemical process with multiple fluctuation subsystems is described in detail.

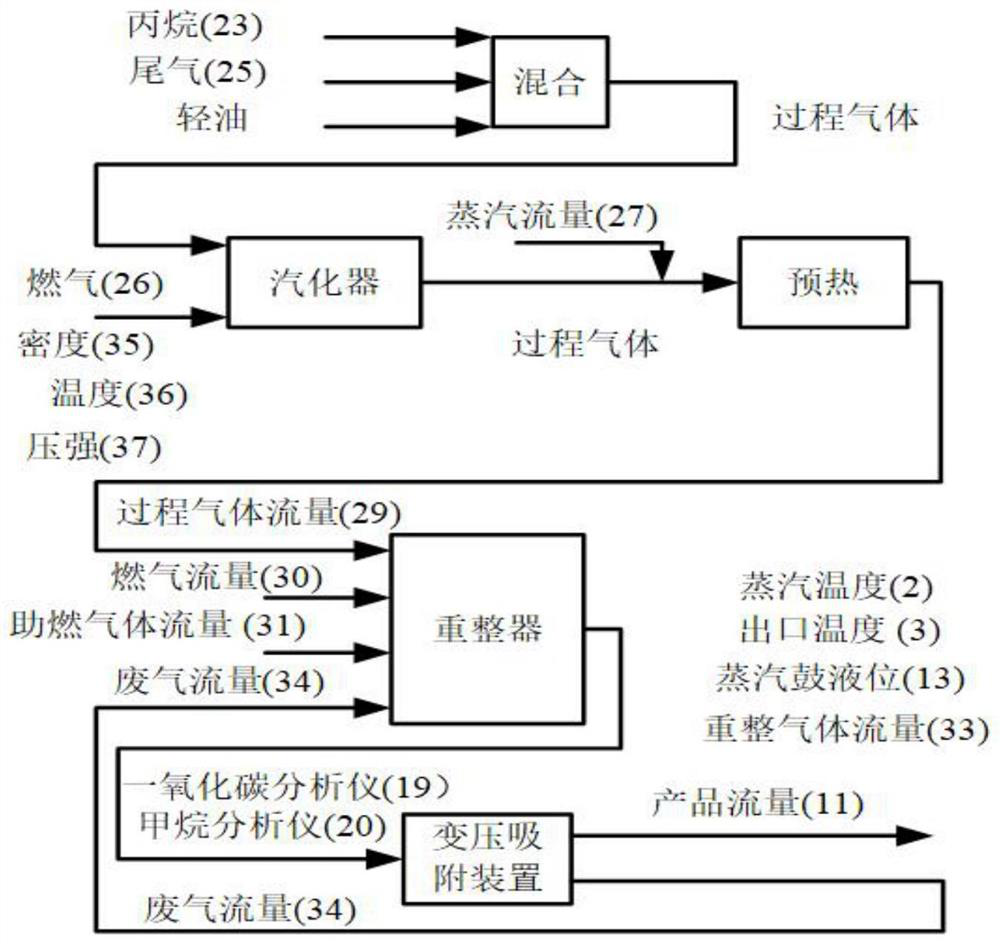

[0103] The hydrogen conversion process of the Southeast Asia refinery in this example is as follows: figure 1 shown.

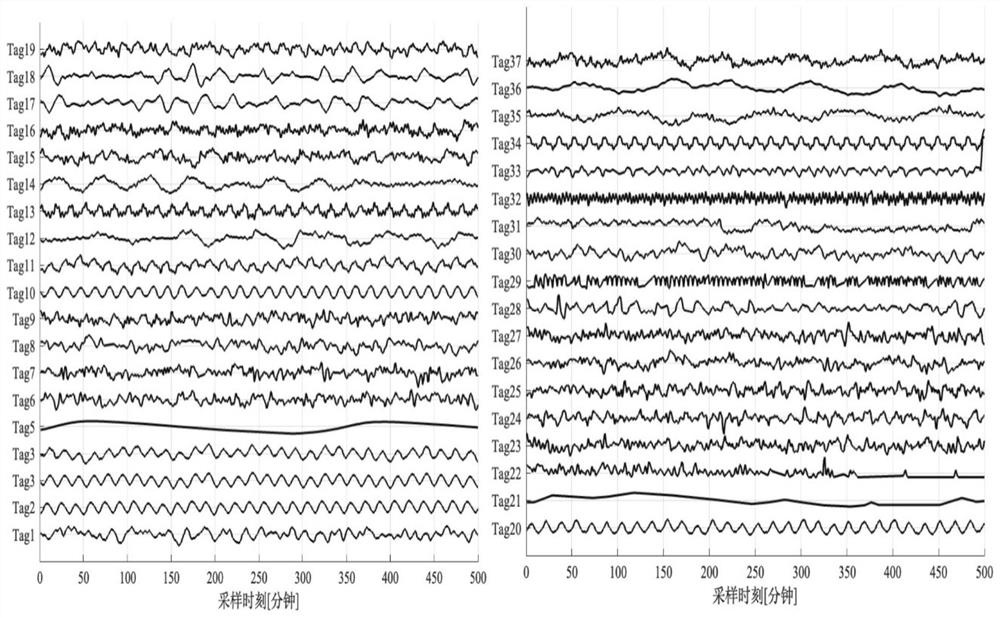

[0104] The process includes a total of 37 variables including controller and indicator process variables. The standardized sample length is 512, and the sampling interval is 1min. Its original time series as figure 2 As shown, it can be seen from the figure that 37 variables fluctuate globally. The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com