Ultrasonic intensity enhancing method suitable for underwater environment laser ultrasonic material detection and application

A laser ultrasonic and underwater environment technology, which is applied in the direction of material analysis, material analysis, and measuring devices through optical means, and can solve problems such as laser ultrasonic excitation intensity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

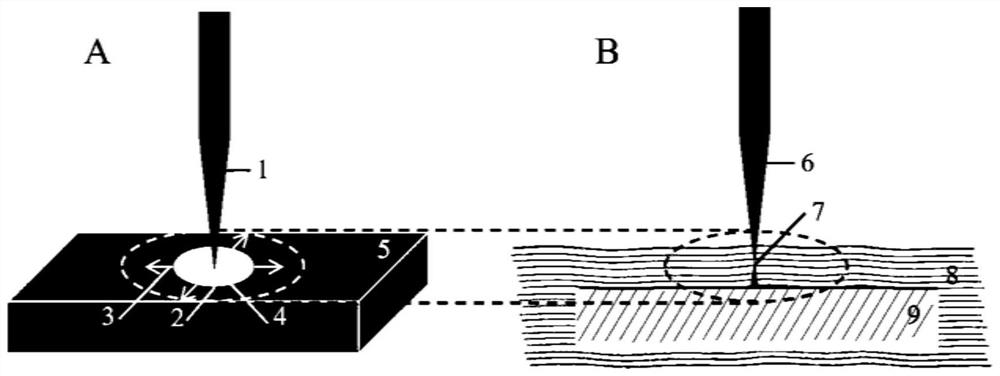

[0029] figure 1 Part A in the middle shows the physical principle of laser ultrasonic material detection, that is, the laser beam that is not enough to cause material surface ablation is irradiated to the material surface, and the thermoelastic effect occurs on the material surface, thereby exciting the ultrasonic wave to propagate into the material, and the ultrasonic wave propagates outward. The transmitted signal will carry the location information of three-dimensional defects or interface features inside the material; figure 1 Part B in the middle shows the ultrasonic enhancement process setting method suitable for underwater laser ultrasonic material detection proposed by the present invention, that is, adjusting the defocus state of the laser pulse on the surface of the material to be detected, and adjusting the positive ionization of the laser pulse relative to the material surface. The coke state is used to induce the cavitation effect to form a cavitation bubble deton...

experiment example

[0042] Take the detection of prefabricated flat-bottomed hole defects on the surface of a 200mm×100mm×3mm metal aluminum plate serving in the underwater environment as an example. The test is based on the defocus-free state testing device and process conditions of laser ultrasonic material detection, in which the laser pulse wavelength used is 1064nm, the energy is 650μJ, and the pulse width is 7ns. Preset the positive defocus of the laser beam relative to the material surface to be 2.6mm; adjust the position of the material to be detected so that it is 2.6mm away from the laser beam emission position; the laser ultrasonic correlation signal is received and analyzed by the PZT probe. The above-mentioned process conditions are used to perform defect detection in the area to be detected.

[0043] After 5 tests, after obtaining the defect detection results of the material to be detected, the position information of the tested defects is compared with the position information of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com