Bird's nest freeze-drying equipment and freeze-drying process thereof

A bird's nest and equipment technology, applied in the field of bird's nest freeze-drying equipment and its freeze-drying process, can solve the problems of uneven cooling, affecting the quality of finished products, etc., and achieve the effects of improving the uniformity of cooling, improving the quality of finished products, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

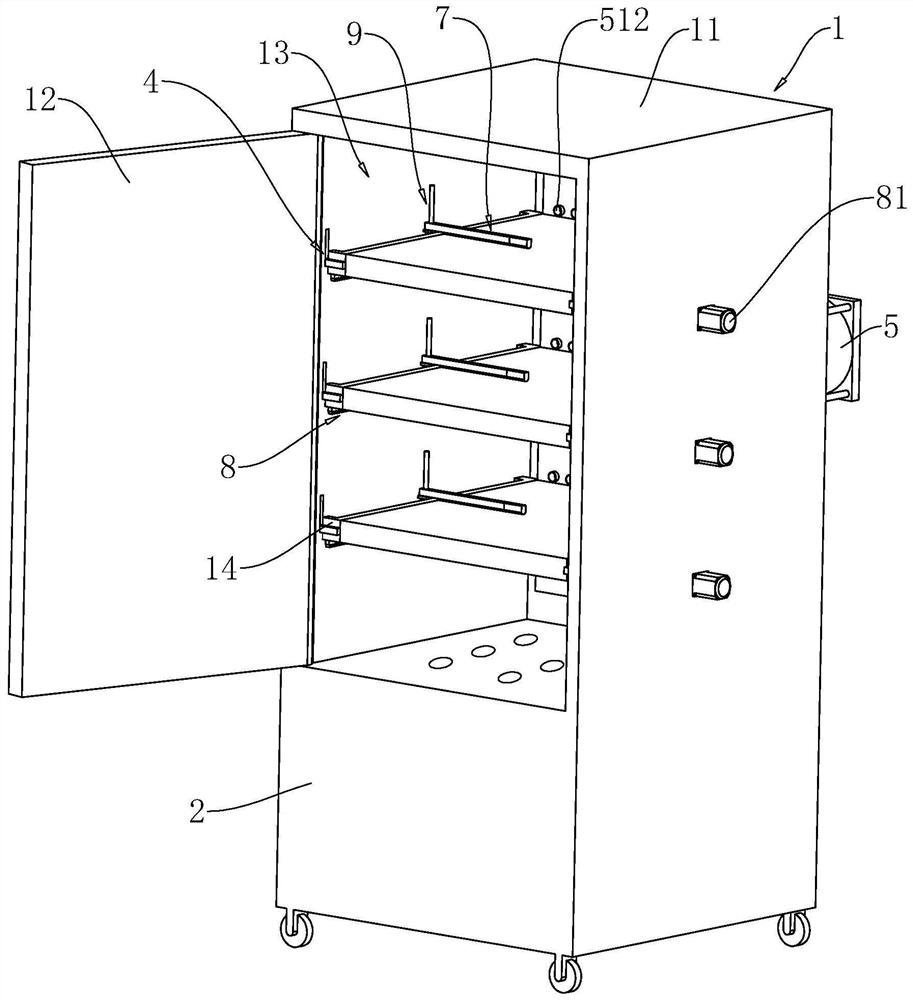

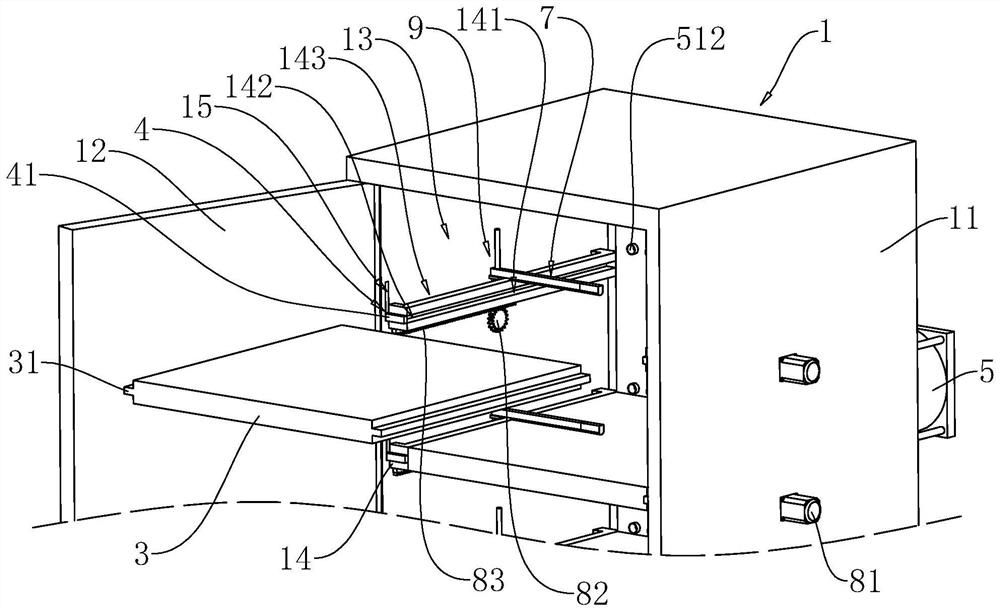

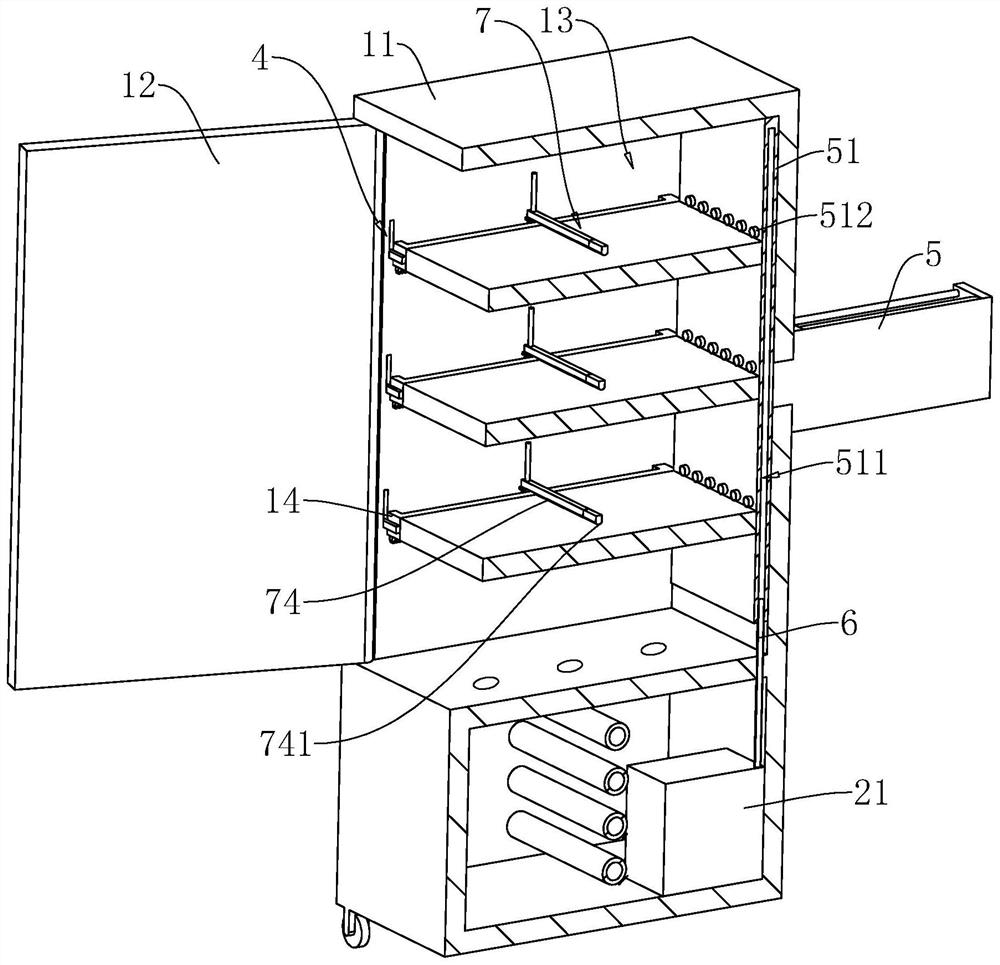

[0042] The following is attached Figure 1-4The application is described in further detail.

[0043] The embodiment of the present application discloses a bird's nest freeze-drying equipment. refer to figure 1 The bird's nest freeze-drying equipment comprises a freeze-drying box 1, and the lower side of the freeze-drying box 1 is connected with a cold trap box 2, and the cold trap box 2 is provided with a pipeline for feeding cold air, thereby reducing the internal temperature of the freeze-drying box 1 . The freeze-drying box 1 comprises a box body 11 and a box door 12 that is hingedly arranged on one side of the box body 11. In this embodiment, the box door 12 is arranged on the front side of the box body 11 to illustrate its structure, and the above-mentioned front side refers to figure 1 The relative orientation in is not an absolute limitation to the position of the box door 12. A freeze-drying cavity 13 with one side opening is provided in the box body 11 , and an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com