Hollow rod watering viscosity reduction device

A hollow rod and viscosity reduction technology, applied in the field of hollow rods, can solve the problems of inconvenient hot water constant temperature, reduced viscosity reduction efficiency, inconvenience of crude oil reflux, etc., to achieve the effect of avoiding uneven water temperature, reducing viscosity reduction efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

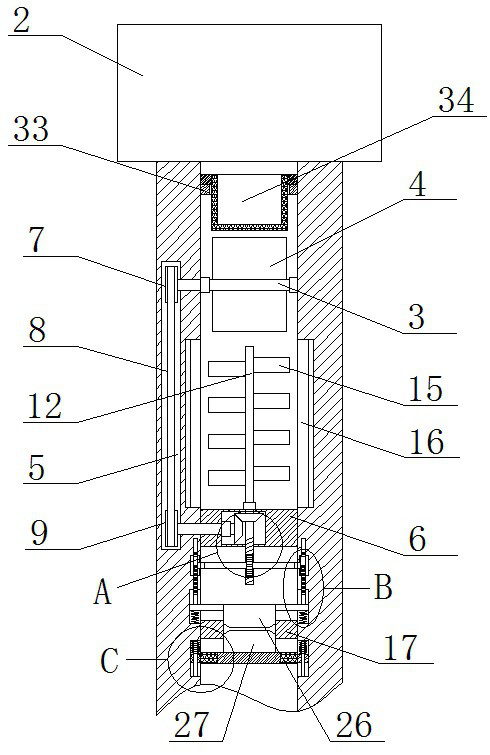

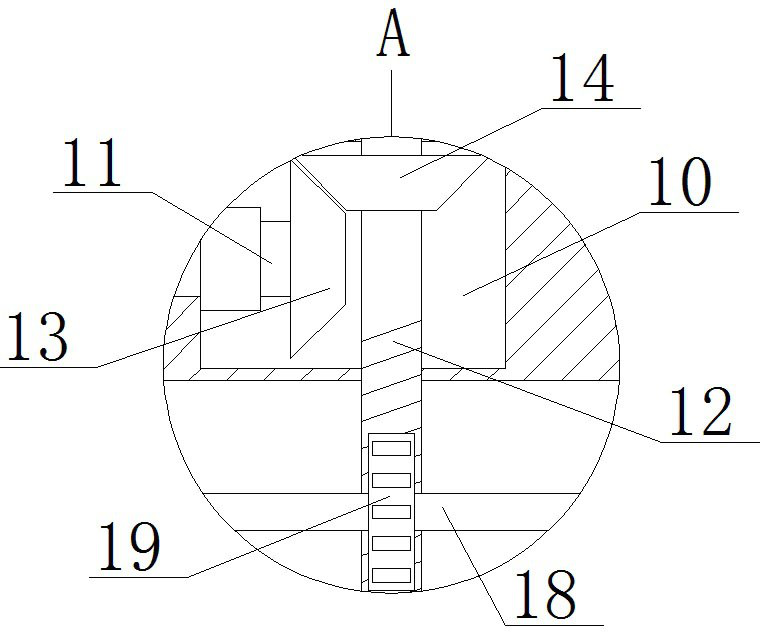

[0026] refer to Figure 1-5 , the hollow rod mixed with water viscosity reducing device, comprising a hollow rod body 1, one end of the hollow rod body 1 is fixedly connected with a water inlet 2 by welding, a first hollow groove 5 is opened in the hollow rod body 1, and the inner wall of the hollow rod body 1 is opened There is a first through hole, and the first rotating shaft 3 is installed in rotation in the first through hole, and two symmetrical water barriers 4 are fixedly installed on the first rotating shaft 3 by welding, and the installation rod 6 is fixedly installed in the hollow rod body 1 by welding , the mounting rod 6 is provided with a second vacant slot 10, a stirring heating mechanism is arranged in the second vacant slot 10, and a second through hole is provided on one side inner wall of the second vacant slot 10, and the second through hole is connected with the first vacant slot 5 communicate with each other, the second rotating shaft 11 is installed in t...

Embodiment 2

[0035] The difference from Embodiment 1 is that one end of the hollow rod body 1 is fixedly connected with the water inlet 2 by welding, the hollow rod body 1 is provided with a first hollow groove 5, and the inner wall of the hollow rod body 1 is provided with a first through hole , the first rotating shaft 3 is installed in rotation in the first through hole, and two symmetrical water shields 4 are fixedly installed on the first rotating shaft 3 by welding, and a limit ring 33 is fixedly installed in the hollow rod body 1. A filter screen 34 is placed, and the installation rod 6 is fixedly installed by welding in the hollow rod body 1. A second empty groove 10 is provided in the installation rod 6, and a stirring and heating mechanism is arranged in the second empty groove 10. One of the second empty groove 10 The side inner wall is provided with a second through hole, the second through hole communicates with the first empty groove 5, the second rotating shaft 11 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com