Garden assembly type rest sentry box

A prefabricated and garden technology, applied to other seating furniture, building types, buildings, etc., can solve the problems of low comfort, easy to catch cold, people feel cold, etc., and achieve the effect of comfortable rest, simple structure and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

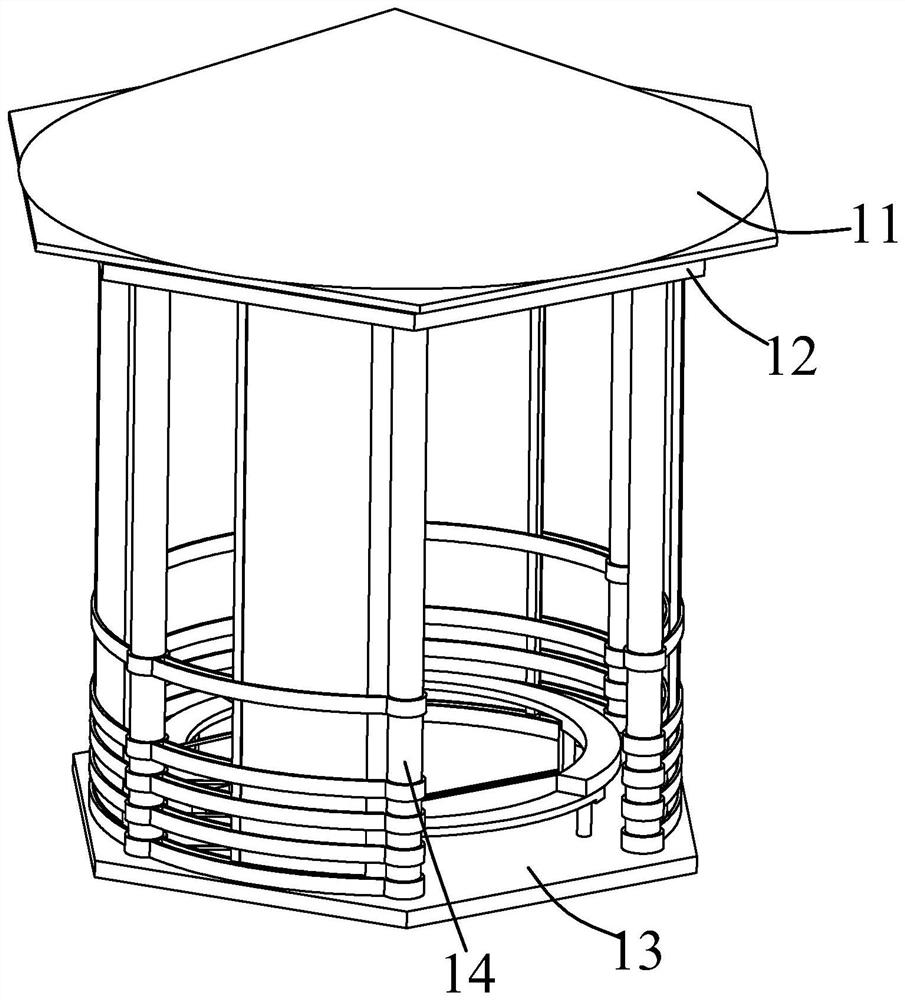

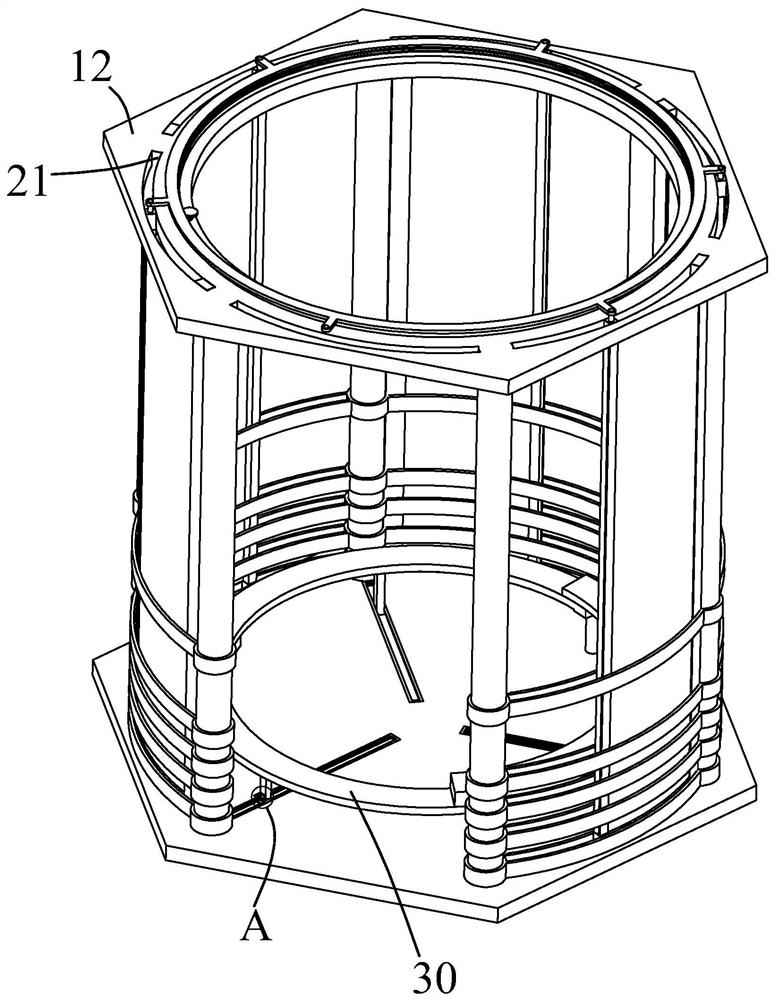

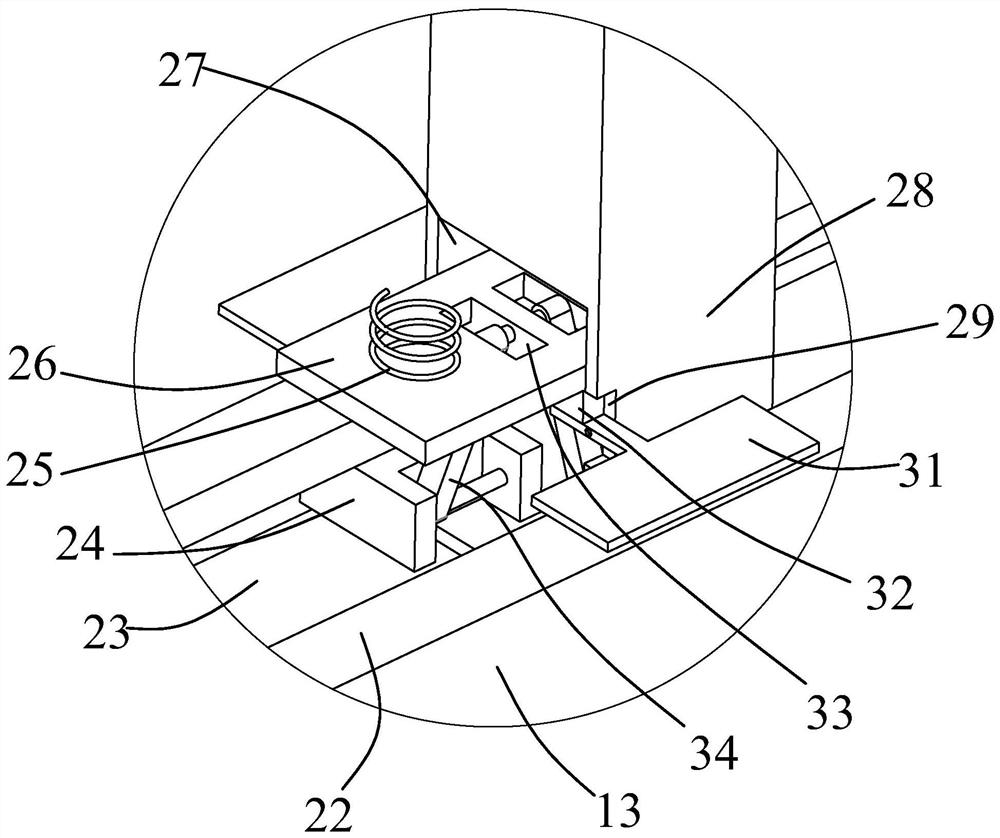

[0030] Such as Figure 1-Figure 12 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. The garden assembly type rest sentry box of the present invention includes a bottom side plate 13 and a top side plate 12. A number of uprights 14 are fixedly arranged between the boards 13, and several mating sleeves 41 are arranged on the outer surfaces of the uprights 14 to slide, and fence boards 42 are fixedly arranged between the mating sleeves 41, and the upper and lower adjacent fence boards 42 are hingedly provided with Side articulated rod 43, the side articulated rod 43 that is positioned at fence board 42 sides forms fork structure, bottom side plate 13 top and top side plate 12 bottoms are provided with mating connecting seat 47, and the hinge point between side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com