Automatic pressure quenching production system for steel rings

A production system, automatic technology, applied in the direction of quenching device, furnace, heat treatment equipment, etc., to achieve the effect of simple operation, stable performance and advanced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

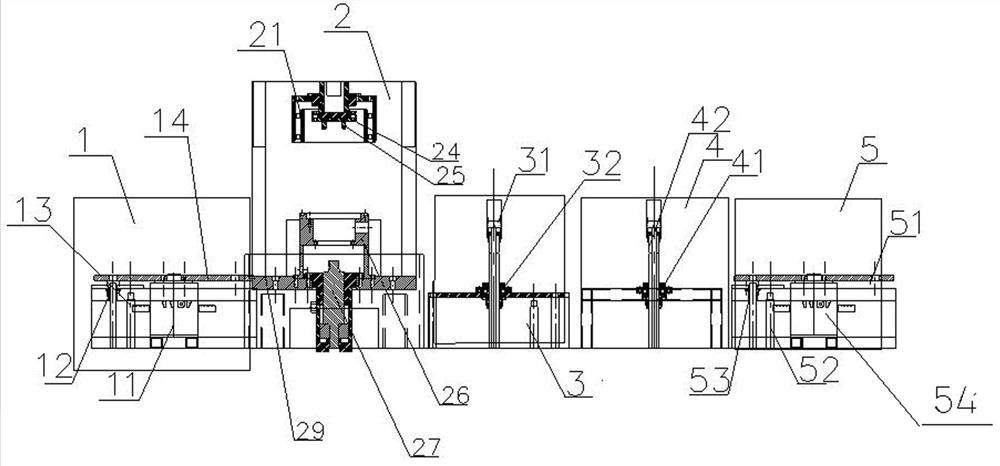

[0024] Such as figure 1 As shown, the steel ring automatic press-quenching production system of this embodiment includes an automatic loading machine tool 5, a tooth alignment machine tool 4, a synchronizer heating device 3, a press-quenching machine tool 2, an automatic blanking machine tool 1, and an automatic loading machine tool. 5 includes that there is a storage carousel 51 on the machine tool, and the storage carousel is provided with storage installation positions uniformly distributed in the circumferential direction, the storage carousel 51 is driven by a motor and positioned by a divider 54, and the bottom of the storage carousel 51 is provided with a ball screw 1 53; The center of the bottom of the material storage carousel 51 is equipped with a splitter-54 to drive the material storage carousel 51 to rotate, and directly below each material storage installation position is connected with a ball screw-53 driven by a servo motor, and the rotation makes the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com