Production process for preparing liquid ammonia from coke-oven gas

A production process and coke oven gas technology, applied in the removal of gas pollutants, gas fuel, combustible gas purification, etc., can solve the problem of maximizing the added value of the exchanger treatment process without optimization, and reduce the overall investment , the effect of increasing production and reducing the total amount of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

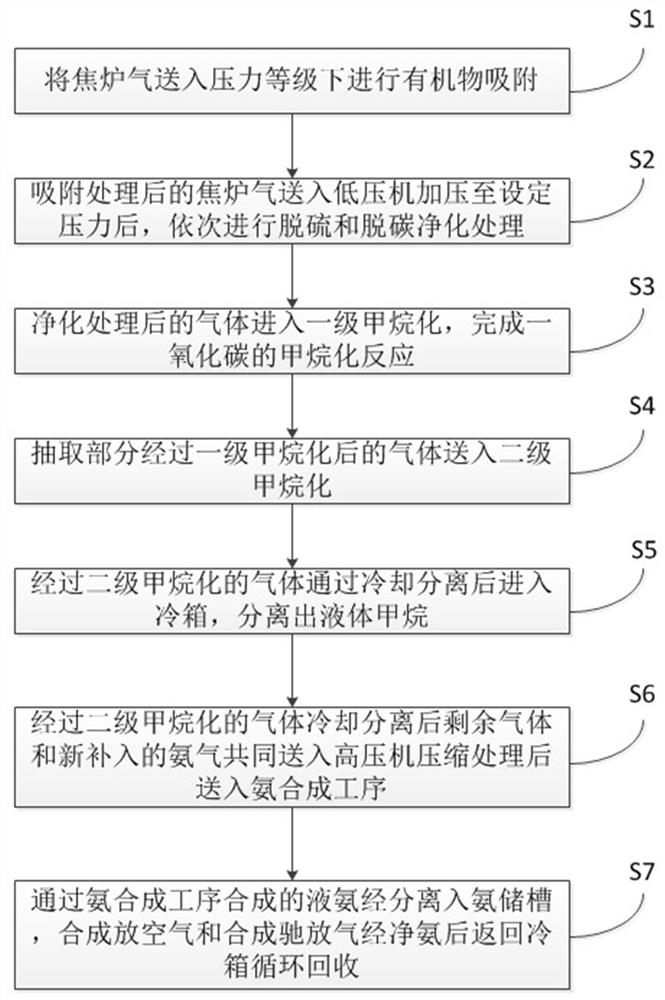

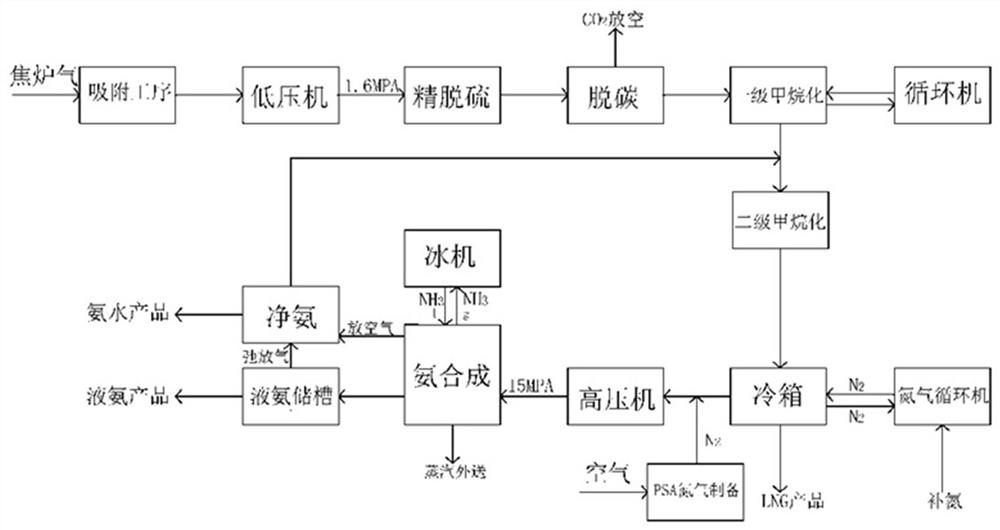

[0036] The application proposes a production process for preparing liquid ammonia from coke oven gas, comprising the following steps:

[0037] S1. Send the coke oven gas to the pressure level for organic matter adsorption;

[0038] S2. The coke oven gas after adsorption treatment is sent to the low-pressure machine to be pressurized to the set pressure, followed by desulfurization and decarburization purification treatment in sequence;

[0039] S3. The purified gas enters primary methanation to complete the methanation reaction of carbon monoxide;

[0040] S4. Extract part of the gas after primary methanation and send it to secondary methanation;

[0041] S5. The gas that has undergone secondary methanation is cooled and separated and then enters the cold box to separate liquid methane;

[0042] S6. After the gas cooling and separation of the secondary methanation, the remaining gas and the newly added ammonia gas are sent to the high-pressure compressor for compression trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com