Scraper conveyer for heading machine

A scraper conveyor and roadheader technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, can solve the problems of low material transportation efficiency, loading and unloading, etc., and achieve the effect of improving material transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions and technical effects of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

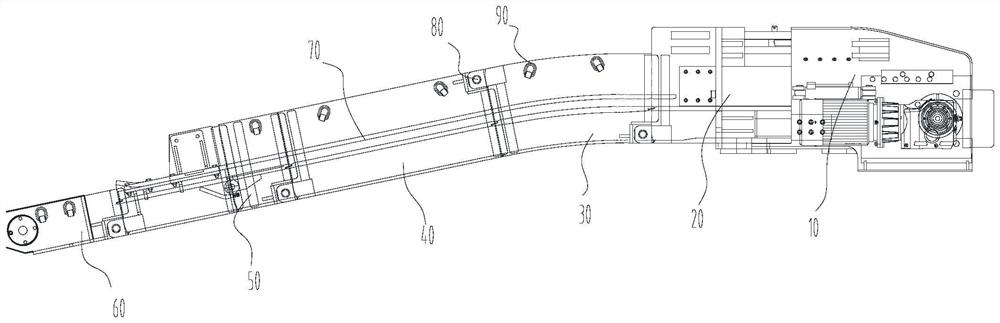

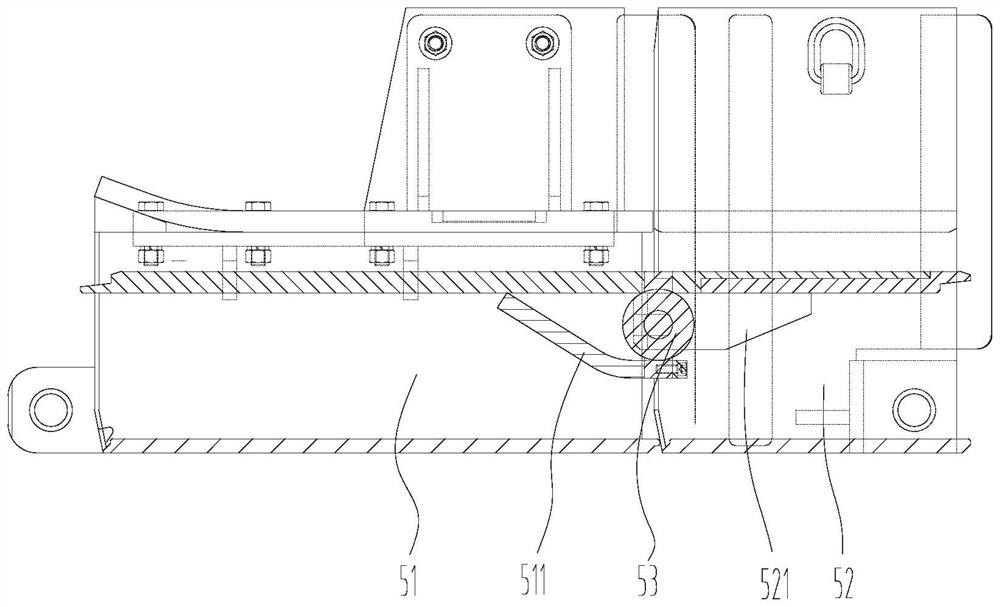

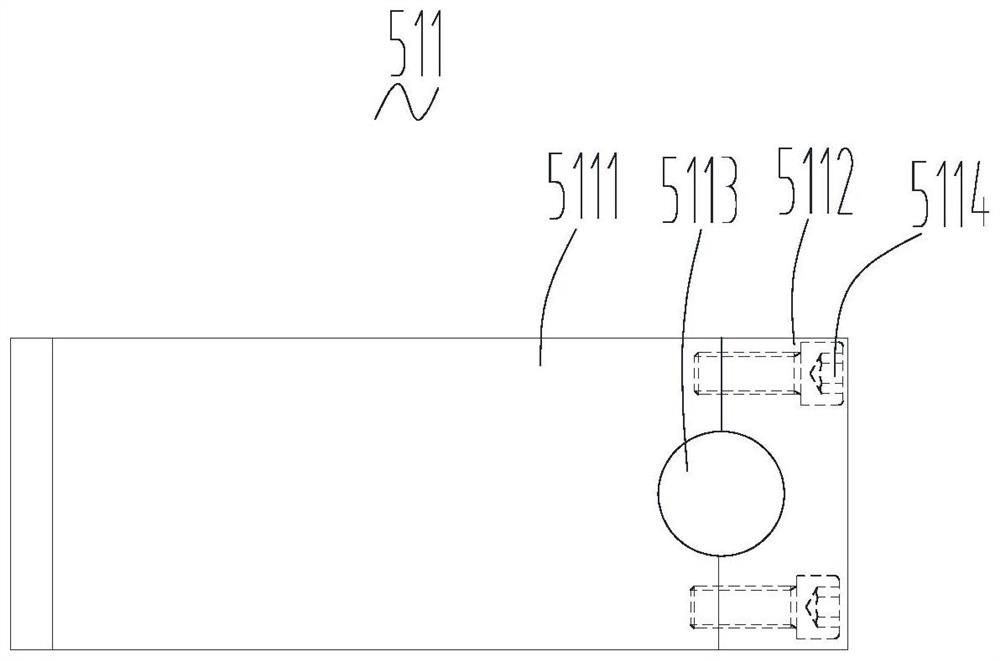

[0026] Please see Figure 1 to Figure 8, the present invention provides a scraper conveyor for roadheaders, comprising a head 10, a conveying trough, a tail 60 and a scraper chain 70, the head 10 and the tail 60 are connected through the conveying trough , the scraper chain 70 is set on the sprockets of the machine head 10 and the tail 60 through the conveying trough, through the scraper chain 70 on the machine head 10, conveying trough, A back-shaped transmission is formed between the tails 60 to realize the conveying of materials; the end of the machine head 10 is provided with a swing pin 11 with a vertical axis. 30 and the middle groove 40, the two ends of the swing pin 11 are connected with the head connection groove 20, and the head 10 can swing laterally aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com