Preparation method of release-paper-free adhesive film wall cloth

A release-free and wall covering technology, applied in chemical instruments and methods, adhesives, non-woven fabrics, etc., can solve problems such as aesthetic impact, heavy adjustment workload, and bulging of wall coverings, so as to ensure production quality and good quality. rate, improve regulation efficiency, and avoid the effect of internal bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

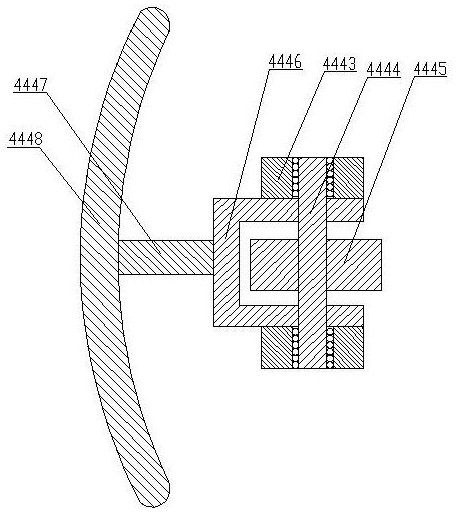

Image

Examples

specific Embodiment approach

[0028] The invention discloses a specific embodiment of a preparation method of a release paper-free adhesive film wall covering, which comprises the following steps:

[0029] S1. Preparation of hot melt adhesive film: by weight, select 80-90 parts of TPU raw material, 1-2 parts of chain extender and 10-20 parts of tackifier into the mixing tank and fully mix to form a mixture , then add 10-15 parts of isocyanate to carry out polymerization reaction, heat to 100-120 ° C, make the mixture in a molten state, form a hot-melt adhesive, and stretch and solidify the polymerized hot-melt adhesive into silk through an extruder , use the high-speed airflow to draw the spinning to the spinning machine to form a hot-melt adhesive film 3, and roll it up for use;

[0030] S2. Select wall cloth base material: prepare jacquard cloth 1 and spunbond non-woven fabric 2, use jacquard cloth 1 as wall cloth fabric, and spunbond non-woven fabric 2 as wall cloth base;

[0031] S3. Positioning wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com