Rubber-lined pipeline, vulcanization process thereof and application of rubber-lined pipeline in nuclear power station

A technology of vulcanized rubber and nuclear power plants, applied in applications, other household appliances, tubular objects, etc., can solve the problems of low adhesion, high defects, and poor stability of rubber linings, and achieve uniform thickness, low defects, and rubber linings full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

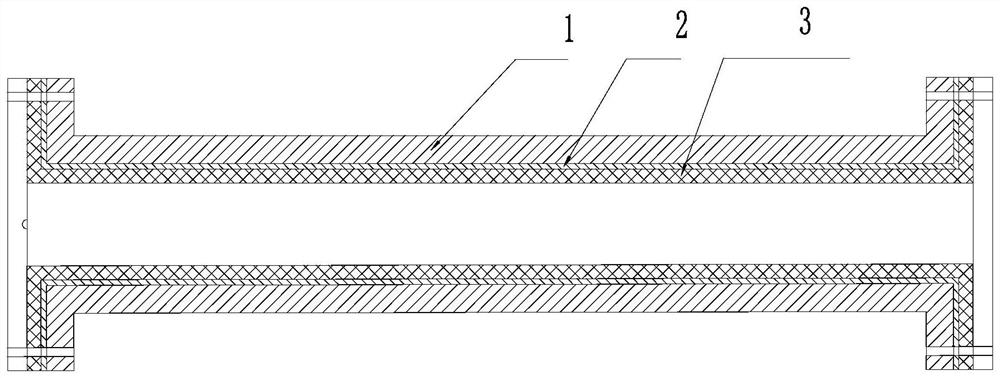

[0089] A rubber-lined pipeline, the vulcanization process of which comprises the steps of:

[0090] ① Sandblasting the inner side and end surface of the carbon steel pipe 1 to remove the oxide layer and rust layer on the surface of the carbon steel; cleaning the sandblasting surface with gasoline to remove dust and oil stains to obtain a clean carbon steel pipe 1;

[0091] ② Coat the inner wall of the carbon steel pipe 1 with adhesive, first coat the primer with Kemlok 607 adhesive, and coat it twice, and after the solvent evaporates and dry, apply the surface with Kemlok 238 adhesive, and coat it twice; form the adhesive layer 2 ;

[0092] ③The formula is: 100 parts of EPDM rubber, 3.5 parts of zinc oxide, 15 parts of N550, 10 parts of gas carbon black, 3 parts of anti-4020, 2 parts of anti-MB, 1.5 parts of anti-D, 0.2 parts of anti-scorch CTP, 3 parts of double 25, 0.5 part of triallyl cyanurate TAC, 0.1 part of p-benzoquinone dioxime GMF, 18 parts of magnesium carbonate, 2...

Embodiment 2

[0096] A rubber-lined pipeline, the difference between its vulcanization process and that of Example 1 is that the phase change material in step ④ is ammonium bicarbonate, the filling amount is 577g, and 1000g of pre-dried clay and other non-decomposable substances are used as diluents , and use after mixing and stirring evenly.

[0097] In step ⑤: stepwise heating: raise the temperature to 30°C and keep for 1h; raise the temperature to 40°C and keep for 1h; raise the temperature to 50°C and keep for 30min; raise the temperature to 60°C and keep for 30min; raise the temperature to 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com