Non-contact glue-pressing type glue dipping device used in winding forming process

A non-contact, winding forming technology, applied in the field of non-contact pressing glue type dipping devices, can solve the problems of difficult glue content control, wound material damage, inconvenient operation, etc., to reduce environmental pollution and material waste, easy to Operation and cleaning, the effect of reducing the volatilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

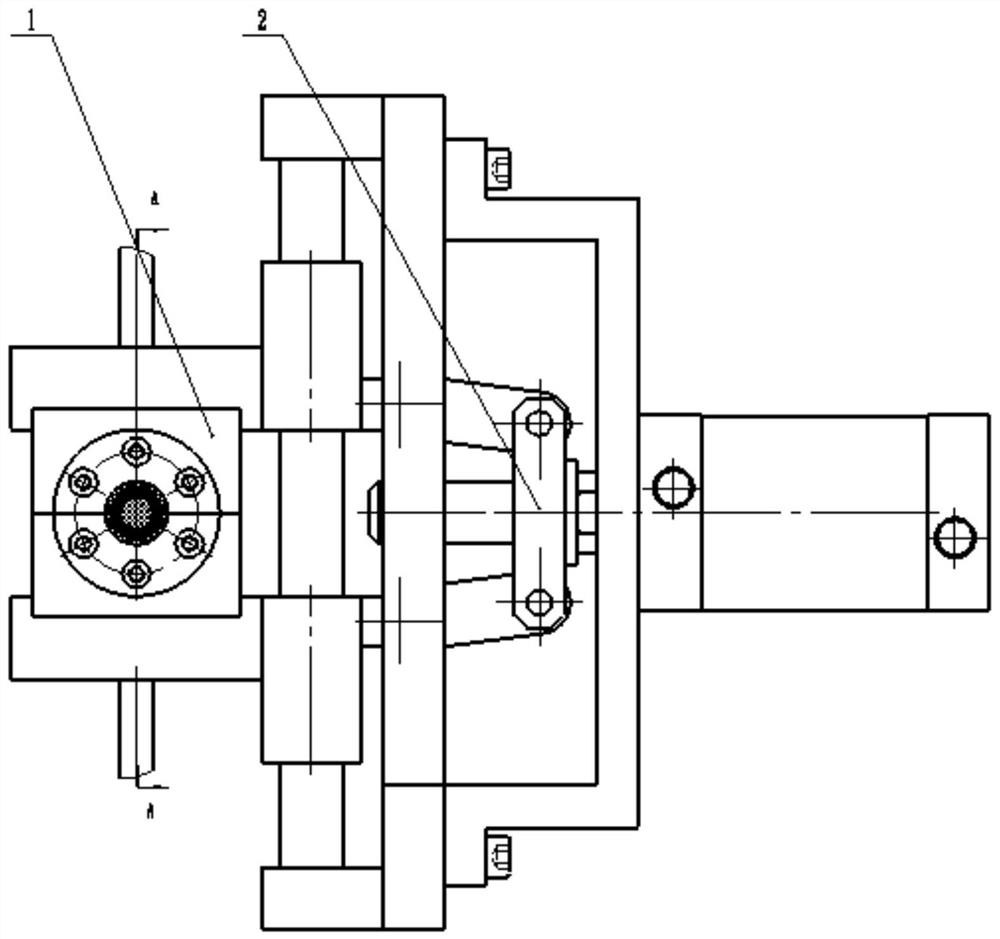

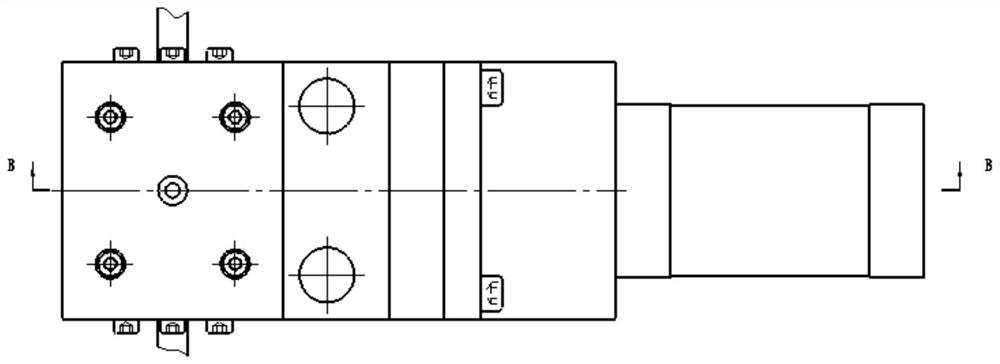

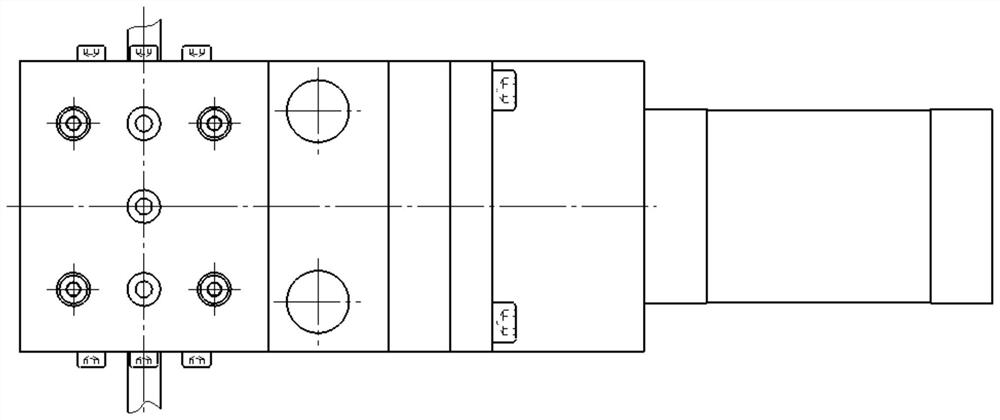

[0031] exist figure 1Among them, a non-contact glue-pressing type dipping device used in the winding molding process is characterized in that: the device includes: a dipping mechanism 1, a synchronous opening and closing drive mechanism 2; the dipping mechanism 1 includes: a pressing block 6 , Mandrel 7, Mandrel 8, Briquetting block 9, Inlet hose 20, Squeegee 21, Wrapping material 22, Squeegee 23, Squeegee 24, Squeegee 25, Outlet hose 26, Inlet hose 27, Outlet Rubber hose 28; synchronous opening and closing drive mechanism 2 includes: bracket 3, optical axis 4, slider 5, slider 10, bracket 11, base 12, cylinder bracket 13, connecting rod 14, sliding sleeve 15, guide post 16, nut 17 , cylinder 18, connecting rod 19. The briquetting block 6 and the core mold 7 are sealed with an O-ring, positioned by the groove on the briquetting block 6, and fixed by screws; the briquetting block 9 and the core mold 8 are sealed by an O-ring, and positioned by the groove on the briquetting blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com