Mouth frame assembly and transparent drawer box manufacturing method

A manufacturing method and technology of drawer boxes, which are applied in the directions of manufacturing tools, workpiece clamping devices, maintenance and safety accessories, etc., can solve the problems of manual manual support and low efficiency, and achieve the effect of easy storage and increased bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

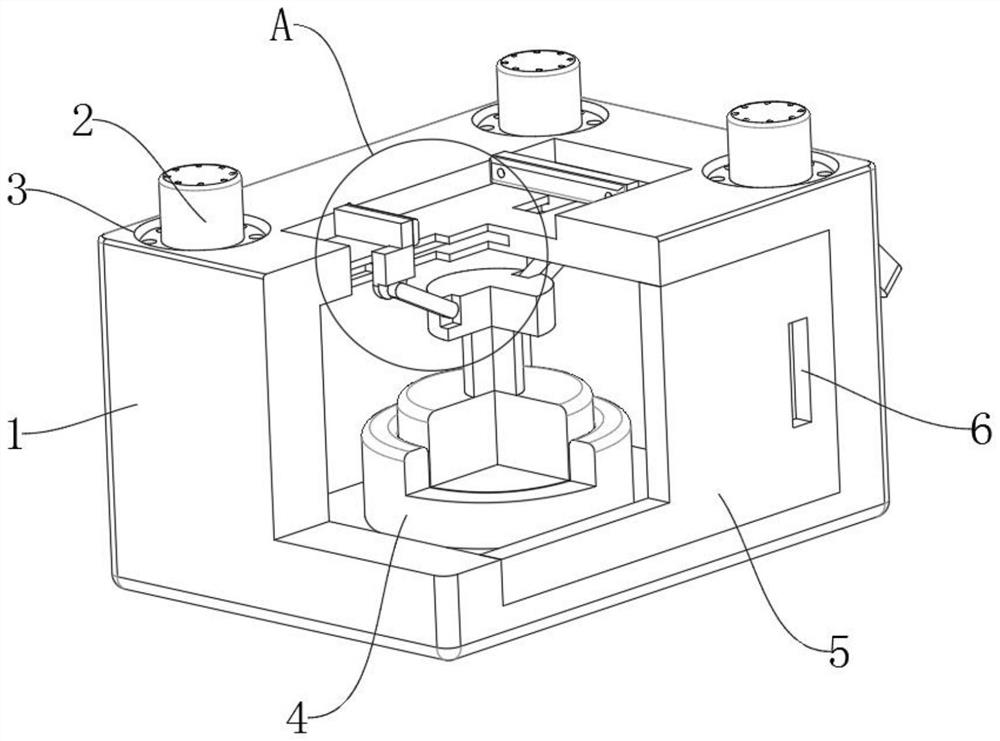

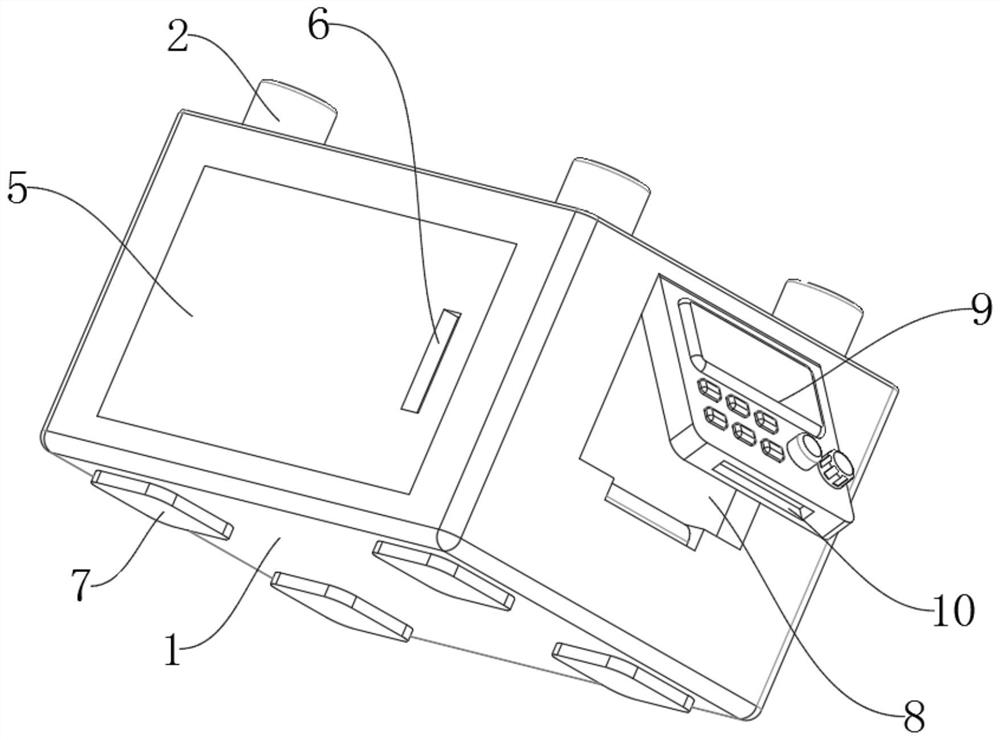

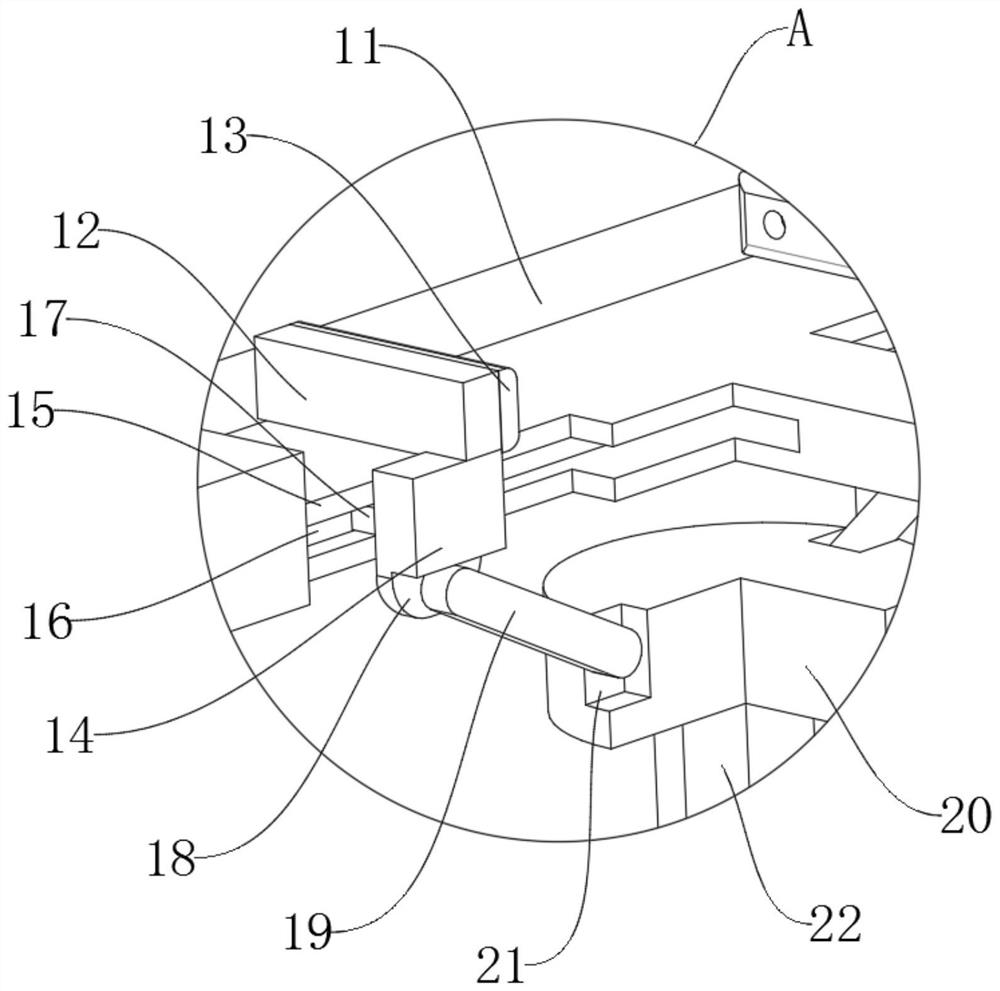

[0021] Example 1, such as Figure 1-3 As shown, the present invention provides a technical solution for the manufacturing method of the mouth frame assembly and the transparent drawer box: including the device body 1, the top of the device body 1 is provided with a limiting groove 11, and the inner bottom surface of the limiting groove 11 is provided near the edges of both sides. There are sliding grooves 15, the inner bottom surface of the device body 1 is fixed with a fixed sleeve 4, the inside of the fixed sleeve 4 is fixed with a cylinder 22, and the top of the cylinder 22 is fixed with a connecting plate 20, and the inner walls of both sides of the two sliding grooves 15 are opened. There are chute 16, and the inside of four chute 16 is slidingly connected with slider 17, and the four sliders 17 are divided into two groups, and the two sliders 17 located in each sliding groove 15 are a group, and each group A sliding block 14 is fixed between opposite sides of the two sli...

Embodiment 2

[0023] Example 2, such as Figure 1-3 As shown, the bottoms of the two sliding blocks 14 are provided with movable grooves 18, and the top of the connection plate 20 is provided with movable openings 21 near both sides, and the insides of the two movable grooves 18 are connected with connecting rods 19 through rotating shafts. One end of the two connecting rods 19 is connected to the inside of the movable port 21 through the rotation of the rotating shaft, the splint 12 is fixed on the top of the two sliding blocks 14, and the rubber pad 13 is fixed on one side of the two splints 12, and the device body 1 The front side of the front side near the side edge is connected with a safety cover 5 by hinge rotation, the front side of the safety cover 5 is provided with a groove 6 near the side edge, and the top of the device body 1 is provided with four fixing grooves 3, four The interior of each fixing groove 3 is fixed with a robot base 2, and the bottom of the device body 1 is fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap