Molten salt heat absorber coating repairing method

A repair method and technology for a salt heat absorber, which can be applied to coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc. Problems such as thermal efficiency of molten salt heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

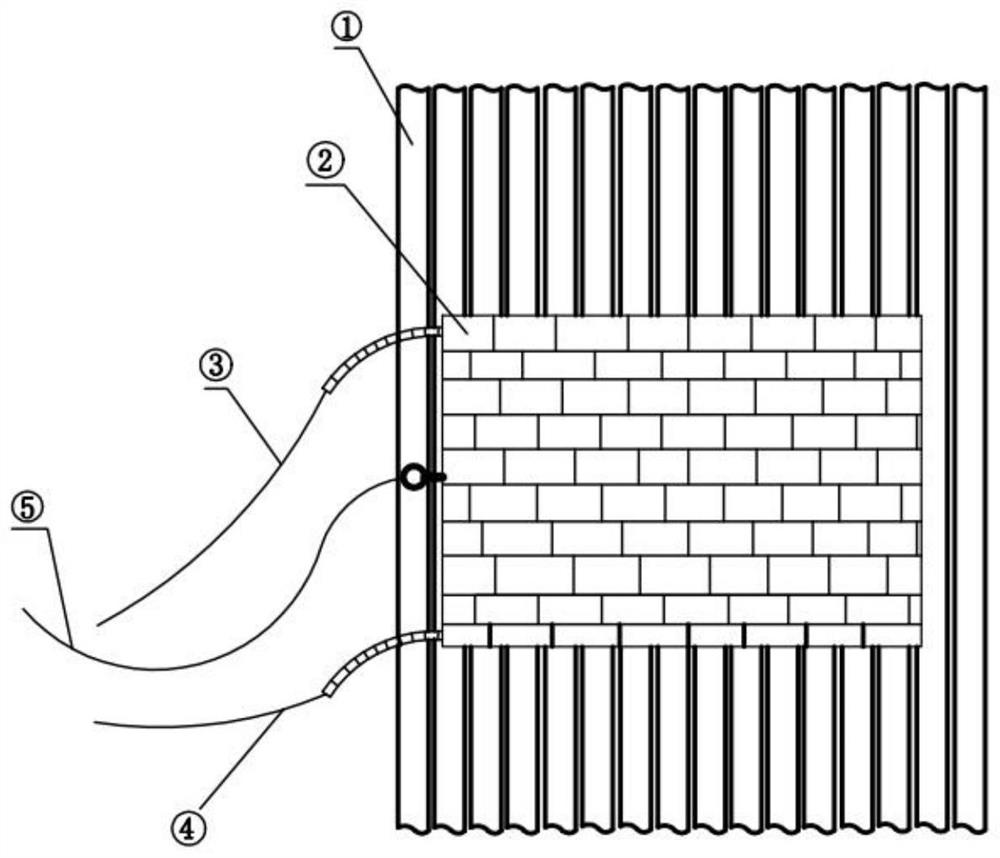

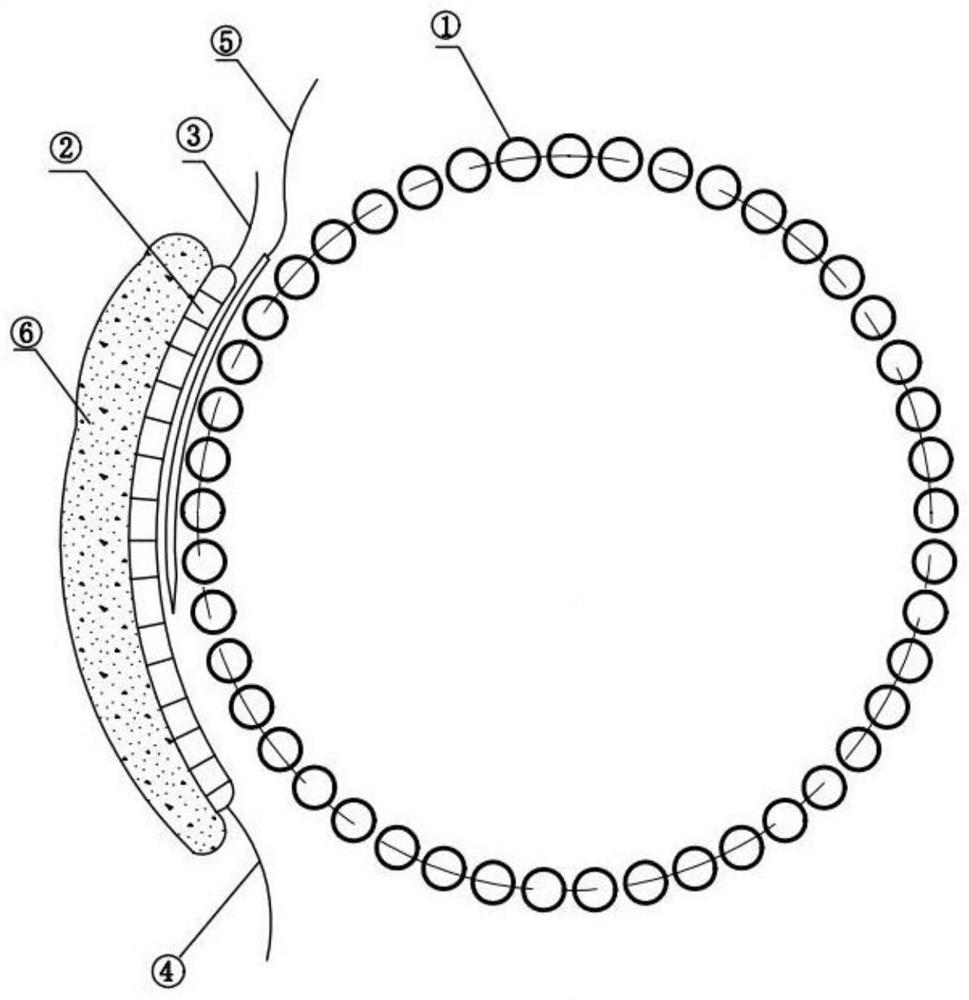

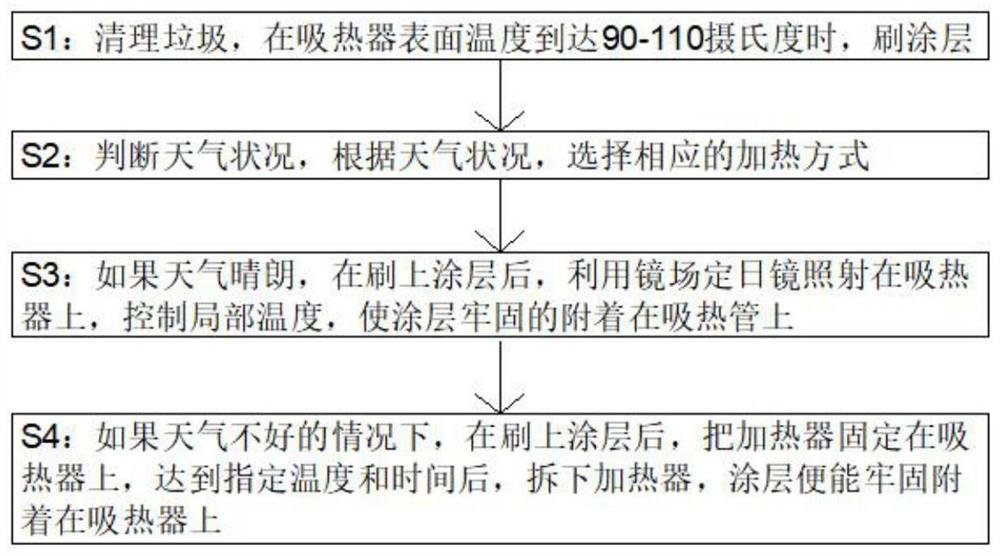

[0026] see Figure 1-4 , in an embodiment of the present invention, a molten salt heat absorber coating repair method, comprising the following steps:

[0027] S1: Clean up impurities, and brush the coating when the surface temperature of the heat absorber reaches 90-110 degrees Celsius;

[0028] S2: Judge the weather conditions, and select the corresponding heating method according to the weather conditions;

[0029] S3: If the weather is fine, after applying the coating, use the field heliostat to irradiate the heat absorber, control the local temperature, and make the coating firmly adhere to the heat absorbing pipe;

[0030] S4: If the weather is bad, after applying the coating, fix the heater on the heat sink, and after reaching the specified temperature and time, remove the heater, and the coating will be firmly attached to the heat sink .

[0031] Preferably, in the step S1, the coating is applied when the surface temperature of the heat absorber reaches 100 degrees ...

Embodiment 2

[0040] see Figure 1-4 , in an embodiment of the present invention, a molten salt heat absorber coating repair method, comprising the following steps:

[0041] S1: Clean up impurities, and brush the coating when the surface temperature of the heat sink reaches 100 degrees Celsius;

[0042] S2: Judge the weather conditions, and select the corresponding heating method according to the weather conditions;

[0043] S3: If the weather is fine, after applying the coating, use the field heliostat to irradiate the heat absorber, control the local temperature, and make the coating firmly adhere to the heat absorbing pipe;

[0044] S4: If the weather is bad, after applying the coating, fix the heater on the heat sink, and after reaching the specified temperature and time, remove the heater, and the coating will be firmly attached to the heat sink .

[0045] Preferably, in the step S4, the heating surface of the electric heater needs to match the shape of the heat sink.

[0046] Pref...

Embodiment 3

[0053] see Figure 3-4 , in an embodiment of the present invention, a molten salt heat absorber coating repair method, comprising the following steps:

[0054] S1: Clean up impurities, and brush the coating when the surface temperature of the heat absorber reaches 90-110 degrees Celsius;

[0055] S2: Judge the weather conditions, and select the corresponding heating method according to the weather conditions;

[0056] S3: If the weather is fine, after applying the coating, use the field heliostat to irradiate the heat absorber, control the local temperature, and make the coating firmly adhere to the heat absorbing pipe;

[0057] S4: If the weather is bad, after applying the coating, fix the heater on the heat sink, and after reaching the specified temperature and time, remove the heater, and the coating will be firmly attached to the heat sink .

[0058] Preferably, in the step S1, the coating is applied when the surface temperature of the heat absorber reaches 100 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com