Rotating shaft oiling device for producing plastic package motor on motor production line

A technology of plastic-encapsulated motor and oiling device, applied in the direction of surface coating liquid device, coating, etc., can solve the problems of reducing production efficiency of production line, unfavorable mass production of motors, inability to apply oil to multiple motor rotating shafts, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

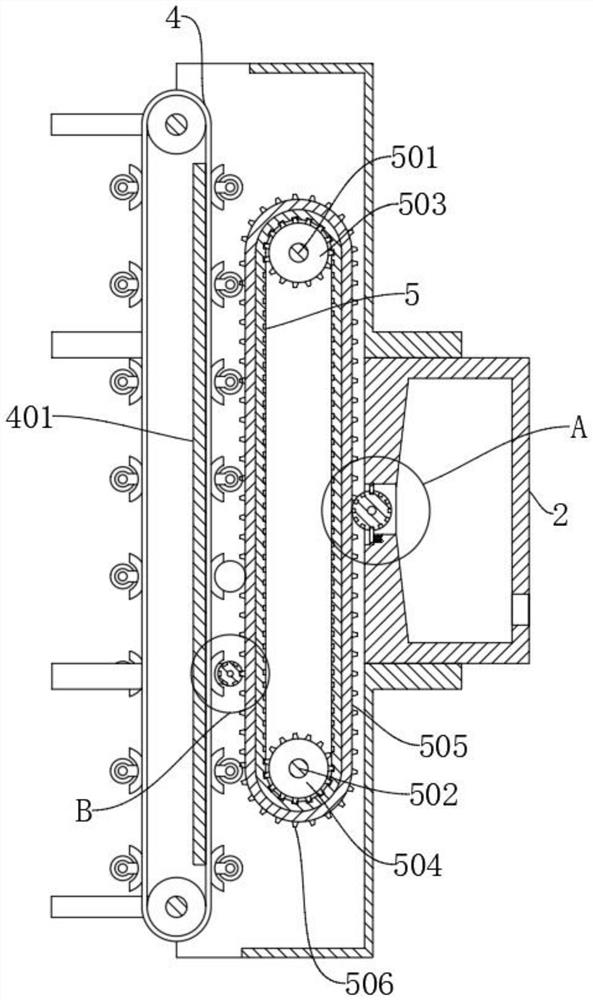

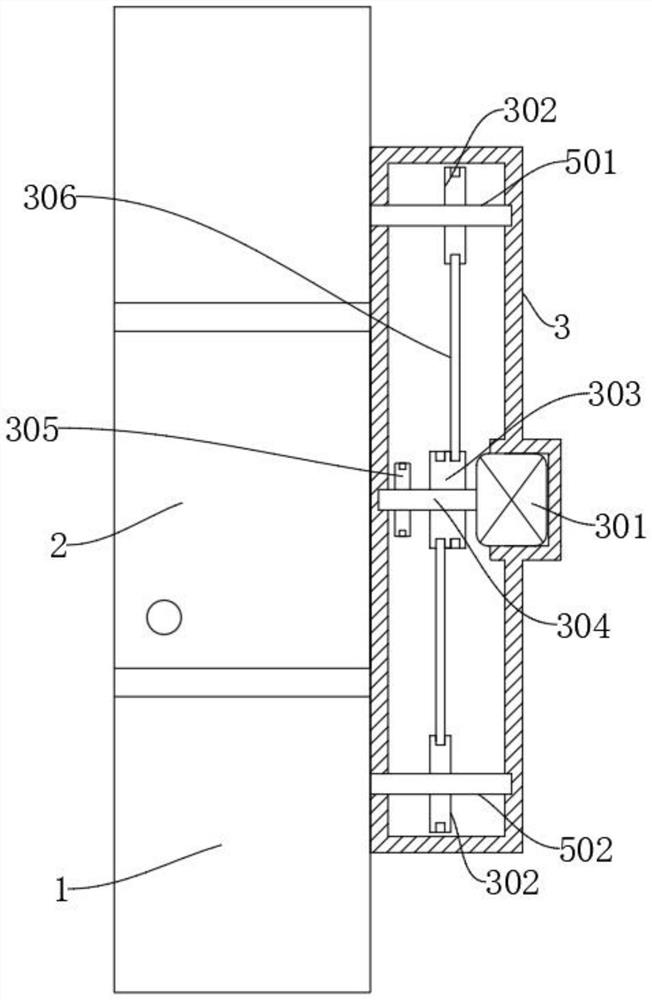

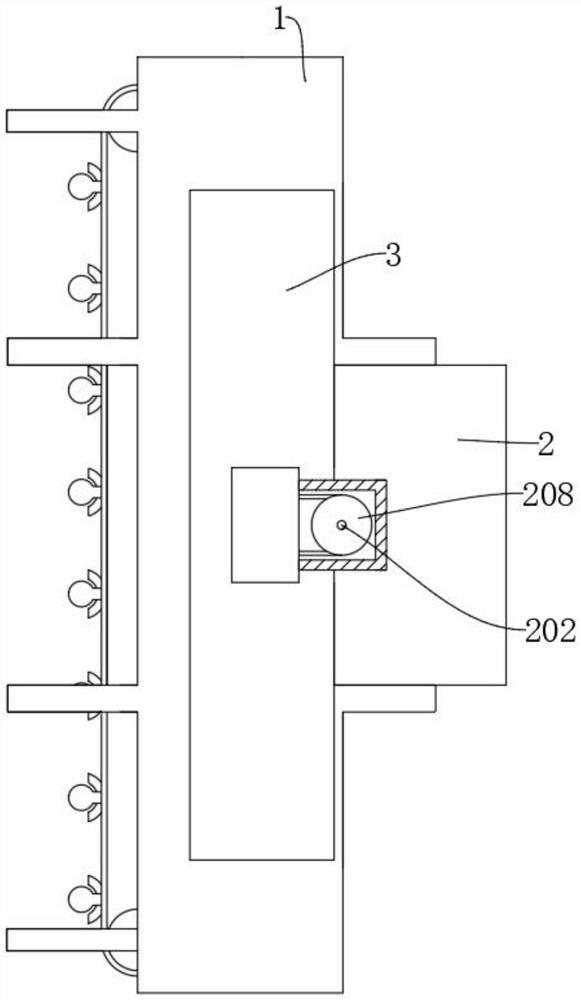

[0035] refer to Figure 1-10 , a motor production line production of plastic-sealed motor shaft oiling device, including a housing 1, a motor shaft, the housing 1 is connected with a transmission belt 4, the lower end of the housing 1 is fixedly connected with a support plate 401, the support plate 401 and the transmission belt 4 phase There are multiple sets of clamping parts connected to the transmission belt 4, the clamping parts are used to clamp the motor shaft, the upper end of the transmission belt 4 is connected with an oiling part, the oiling part is used to oil the motor shaft, and the upper end of the housing 1 is fixed The oil storage tank 2 is connected, and the lower end of the oil storage tank 2 is connected with an oil discharge part, and the oil discharge part is used to discharge the oil to the oiled part. , the power unit is used to power the oiled parts.

[0036]When using this device, first place the motor shaft on the arc block 402, and by compressing th...

Embodiment 2

[0041] refer to figure 1 , Figure 5 , Figure 6 , Figure 7 , a rotating shaft oiling device for producing plastic-encapsulated motors on a motor production line, which is basically the same as in Embodiment 1, and furthermore: the clamping part includes a support block 405, and a plurality of groups of support blocks 405 are symmetrically fixedly connected to both sides of the transmission belt 4, and the support block 405 is rotatably connected with a fourth rotating shaft 403, and the fourth rotating shaft 403 is fixedly connected with a rotating wheel 404. The rotating wheel 404 is provided with multiple groups of rotating grooves 406, so as to facilitate the rotating wheel 404 to rotate.

Embodiment 3

[0043] refer to Figure 6 , Figure 7 , a rotating shaft oiling device for producing plastic-sealed motors on a motor production line, which is basically the same as in embodiment 1, and furthermore: a clamping rod 408 is slidably connected in the fourth rotating shaft 403, and a second spring 407 is connected in the fourth rotating shaft 403 , both ends of the second spring 407 are fixedly connected with the clamping rod 408 and the fourth rotating shaft 403 respectively, and the symmetrical clamping rods 408 are used to clamp the motor rotating shaft, which is convenient for clamping the motor rotating shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com