Matrix treatment method and tobacco seed seedling raising method using matrix

A technology for substrate treatment and tobacco seeds, applied in planting substrates, tobacco cultivation, botany equipment and methods, etc., can solve the problems of not being able to improve the quality of tobacco seedlings, achieve good application prospects, and the method is simple and easy to improve the quality of tobacco seedlings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

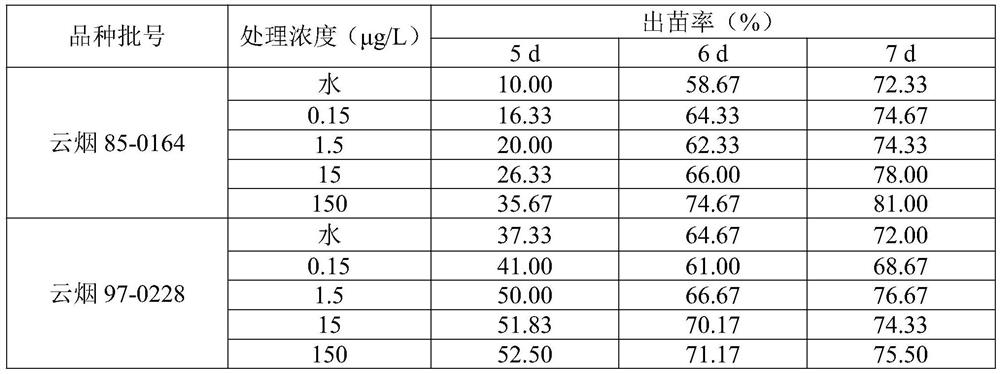

[0038] Three batches of naked tobacco species of different varieties were taken, numbered respectively as Yunyan 85-0164, Yunyan 97-0228, and MSK326-0402.

[0039] 1.1 Take the commercially available tobacco substrate, pour it into a mesh sieve with a pore size of 5 mm, shake and sieve it, remove impurities or stones with excessive particle size, and crush the substrate bonded into blocks for later use. Prepare 2mg / L butenolide mother liquor, then get mother liquor and be mixed with 0.15μg / L, 1.5μg / L, 15μg / L, 150μg / L butenolide solution respectively.

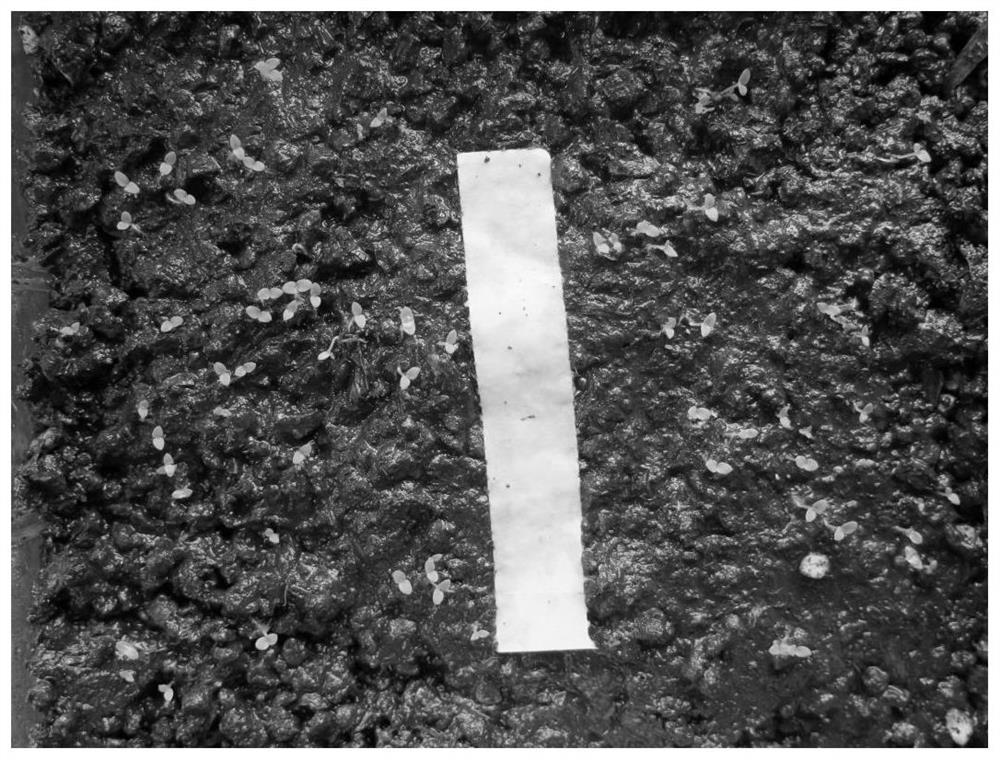

[0040] 1.2 Comparative example: Take 100g of sieved substrate, spread it in a 570ml germination box, add 80ml of water, mix evenly; spread the substrate, and evenly sow 100 grains of the above-mentioned 3 batches of tobacco bare seeds in each box, Do 3 repetitions, place at 25°C for seedling emergence test, spray water during the period to keep the substrate moist, and count the seed emergence rate in 5 to 7 days. The statistica...

Embodiment 2

[0048] The difference between the present embodiment 2 and embodiment 1 is that the tobacco seeds sown are 3 batches of seeds of the same variety with different storage years (different vigor): 2001-0064, 2002-0138, 2014-2882. After sowing, the seeds were first placed in a low temperature treatment at 5°C for 4 days, then transferred to 25°C for emergence, and the seed emergence rate was counted on the 7th day after transfer to 25°C, which was used as the result of the determination of seed cold resistance activity.

[0049]It can be seen from Table 2 that when the substrate mixed with butenolide is used for seedling cultivation, after the seeds encounter low temperature stress, the normal emergence temperature is restored, and the seeds in the substrate containing 0.15-15 μg / L butenolide solution The emergence rate is higher than that of the water-containing medium. For example, the emergence rate of the seeds of 2002-0138 in the 0.15-15 μg / L solution-treated medium increased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com