Electrolyte for lithium secondary battery and lithium secondary battery comprising same

A lithium secondary battery and electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, lithium batteries, etc., can solve the problem of accelerating the side reaction between the electrolyte and the electrode, increasing the thickness of the electrode and the internal resistance of the battery, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 4

[0143] Except adding the compound represented by Chemical Formula 8 (Example 1), Chemical Formula 9 (Example 2), Chemical Formula 10 (Example 3) or Chemical Formula 11 (Example 4) in an amount of 1% by weight based on the total weight of the electrolytic solution In addition, a lithium secondary battery sample was produced by the same method as in Comparative Example 1.

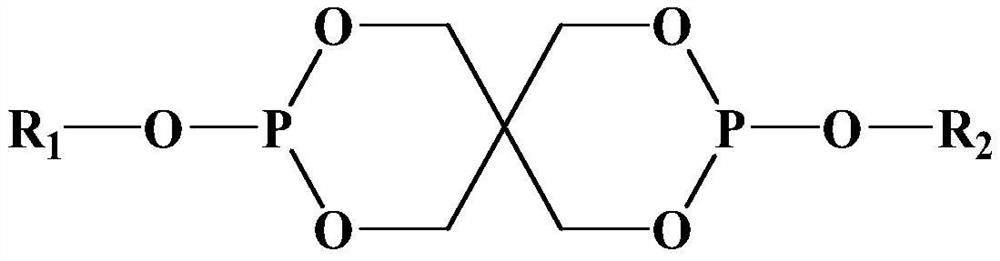

[0144] [chemical formula 8]

[0145]

[0146] [chemical formula 9]

[0147]

[0148] [chemical formula 10]

[0149]

[0150] [chemical formula 11]

[0151]

Embodiment 5 to Embodiment 8

[0153] In addition to adding 0.5% by weight (Example 5), 0.4% by weight (Example 6), 3% by weight (Example 7) and 4% by weight (Example 8) based on the total weight of the electrolyte A lithium secondary battery sample was produced by the same method as in Comparative Example 1 except for the compounds shown.

experiment example 1

[0154] Experimental example 1: Evaluation of initial performance (room temperature, 25°C)

[0155] (1) Evaluation of initial capacity

[0156] The batteries of Examples and Comparative Examples were charged (0.5C-rate CC / CV, 4.2V; 0.05C cut-off) and discharged (0.5C-rate CC; 2.7V cut-off) three times. The discharge capacity of the third cycle was measured as the initial capacity of the battery.

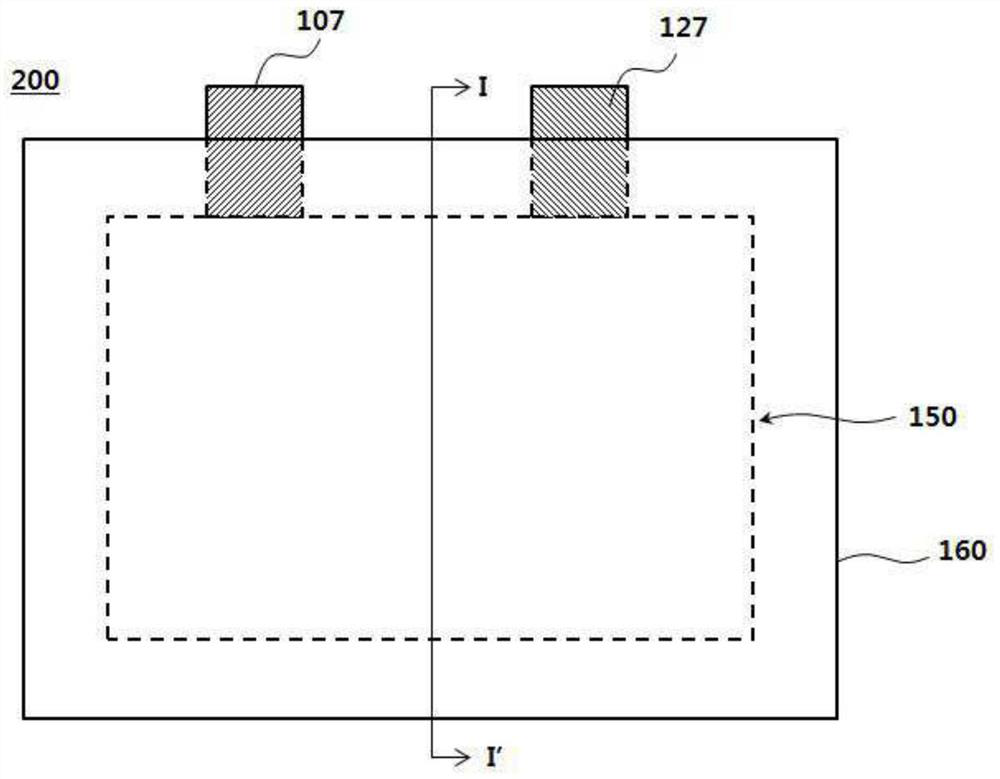

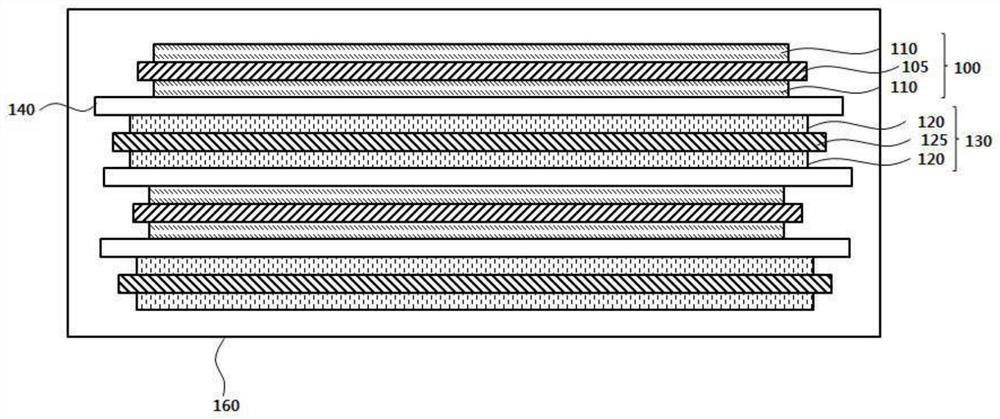

[0157] (2) Evaluation of the initial thickness of the battery

[0158] The batteries of Examples and Comparative Examples were charged at room temperature (0.5C-rate CC / CV, 4.2V; 0.05C cut-off), and then using a plate thickness measuring device (Mitutoyo Corporation, Japan, 543- 490B) to measure the thickness of the battery.

[0159] (3) Evaluation of internal resistance (charging DC internal resistance (C_DCIR) and discharging DC internal resistance (D_DCIR))

[0160] At the point where the SOC is 60%, change the C-rate to 0.2C, 0.5C, 1.0C, 1.5C, 2.0C, 2.5C, and 3.0C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com