Anti-freezing module of closed cooling tower

A closed cooling tower, antifreeze technology, applied in water shower coolers, direct contact heat exchangers, heat exchange equipment, etc., can solve the problems of condensing coil damage, clean water, inconvenience, etc., to reduce The effect of the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

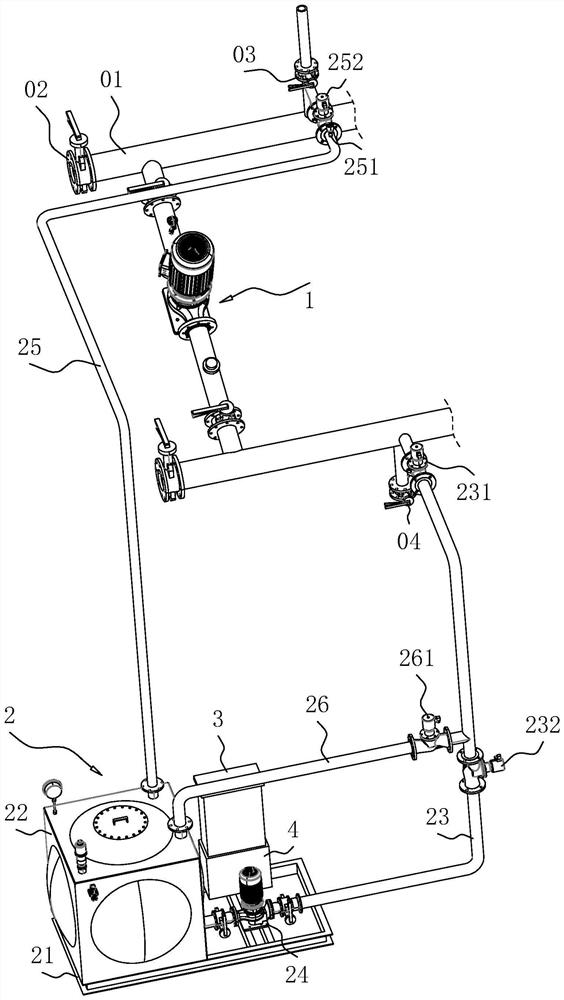

[0038] The following is attached Figure 1-3 The application is described in further detail.

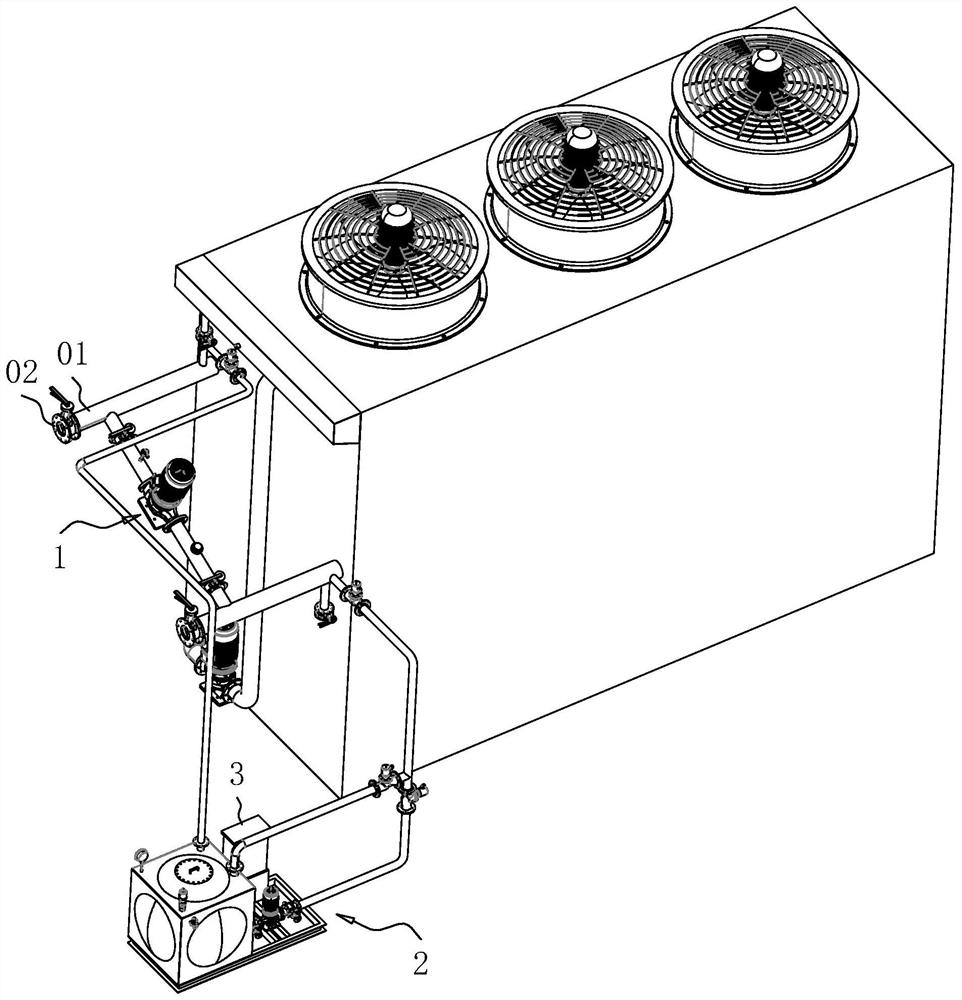

[0039] The embodiment of the present application discloses an antifreeze module of a closed cooling tower. refer to figure 1 , a closed cooling tower antifreeze module includes a microcirculation device 1, an antifreeze filling device 2 and a controller 3, the microcirculation device 1 is arranged between the water inlet end and the water outlet end of the condensing coil 01, and the antifreeze filling device 2 is arranged on one side of the cooling tower, and the microcirculation device 1 and the antifreeze filling device 2 are both electrically connected to the controller 3. The controller 3 is used to control the operation of the microcirculation device 1 and the antifreeze filling device 2, so as to facilitate the antifreeze protection of the condensation coil 01.

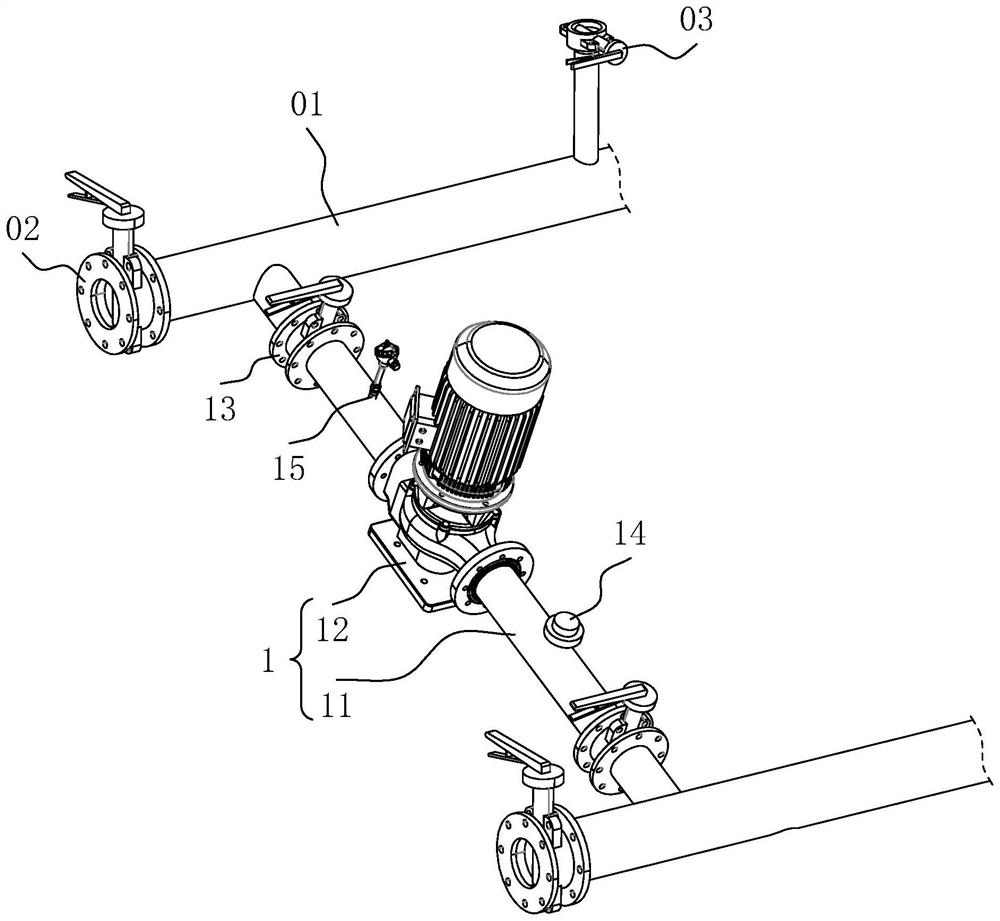

[0040] refer to figure 2 , the microcirculation device 1 includes a communication pipe 11 and a circulating wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com