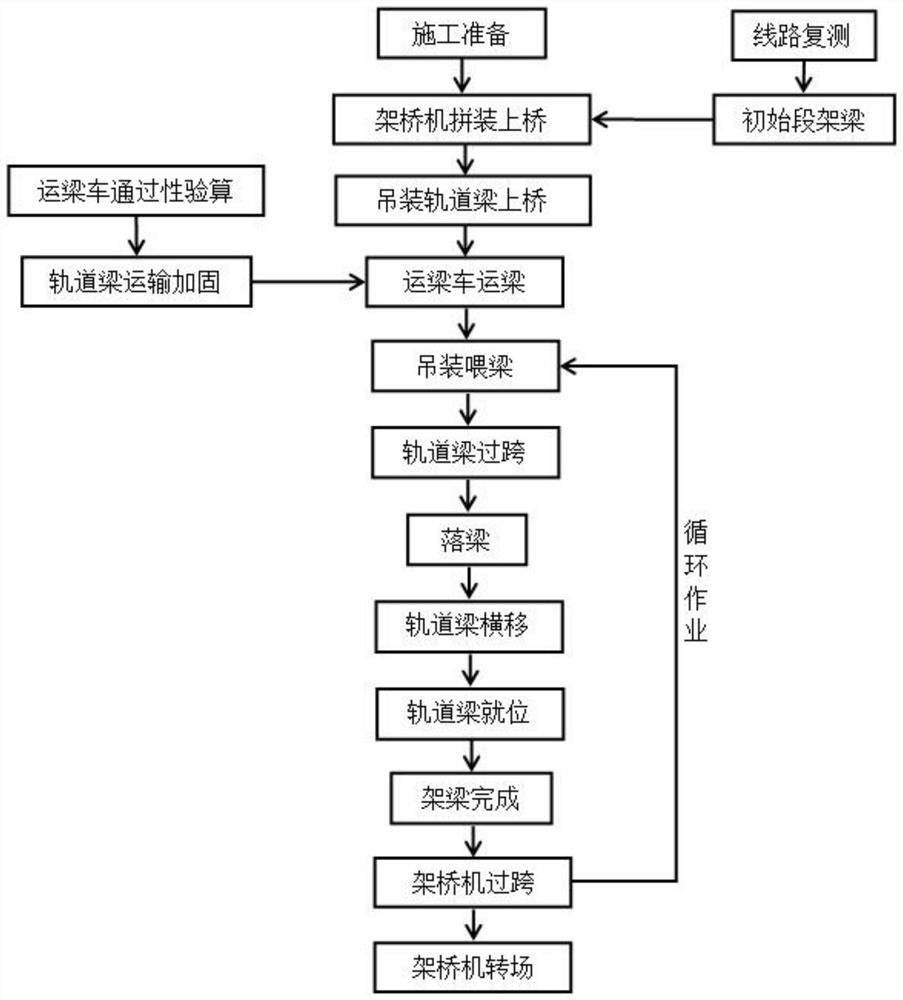

Built-in maglev elevated line bridge erecting machine frame girder construction method

A technology for elevated lines and construction methods, which is applied in the field of rail transit, and can solve the problems of lack of construction methods for embedded magnetic levitation track beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

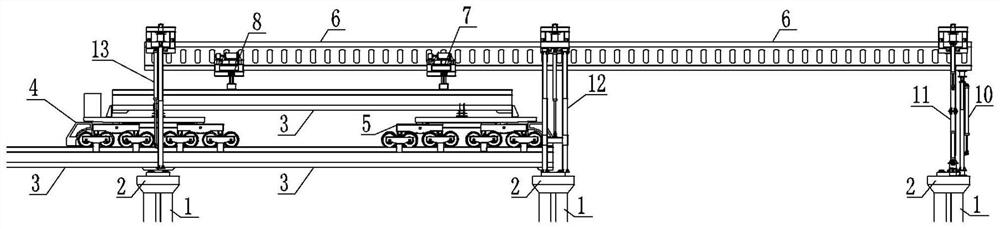

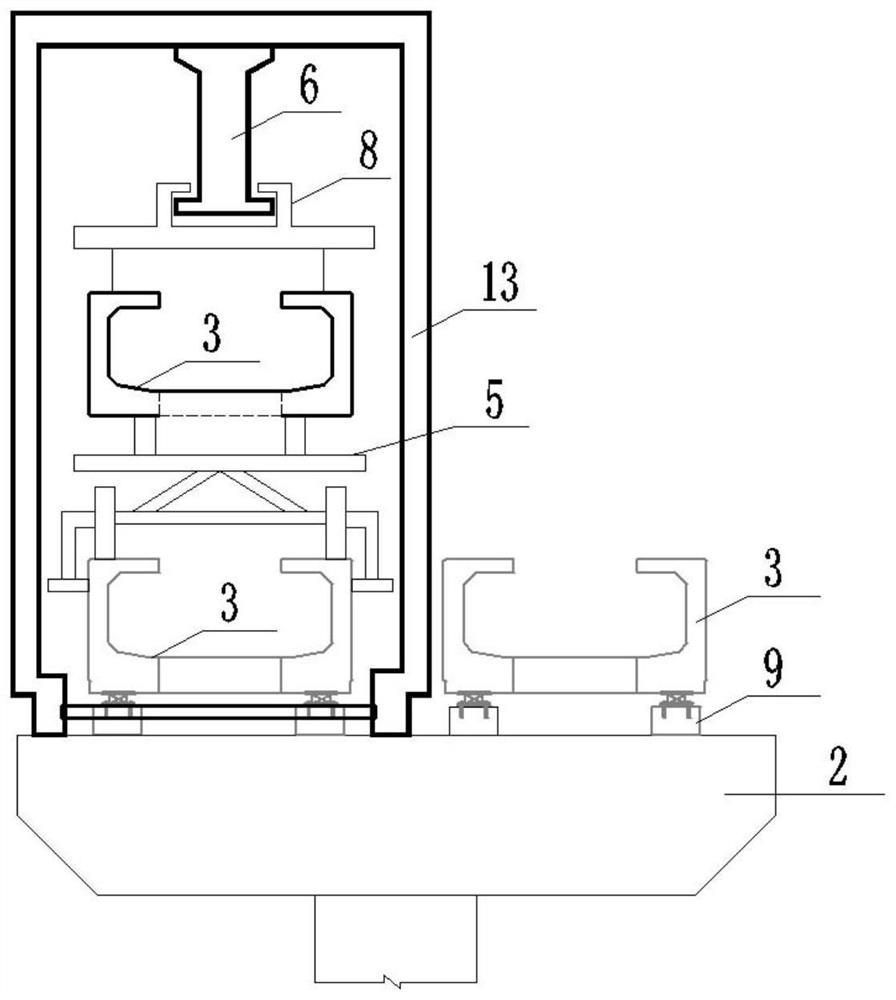

[0035] refer to Figure 1 to Figure 7 as shown, figure 1The number 1 is the bridge pier, and the number 2 is the cover beam. The construction of the bridge pier is a necessary construction content in the early stage. The track beam bridge pier is generally a reinforced concrete structure. No. 3 is the track beam. The track beam has been assembled in the special beam assembly tool before erection, and the post-cast concrete at the mid-span and beam end has reached the required strength of the hanging beam. The prestressed steel beam of the track beam has been prestressed. pull construction. No. 4 is the No. 1 beam transport vehicle, and No. 5 is the No. 2 beam transport vehicle. Each beam transport vehicle can be independently controlled to start and stop. At the same time, two beam transport vehicles can also be grouped to start and stop synchronously. For beam transport vehicle load, each beam transport vehicle is designed with 8 sets of traveling wheel sets and 4 sets of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com