Fracturing flow-back fluid treatment method

A technology of fracturing flowback fluid and treatment method, which is applied in the fields of filtration treatment, sedimentation treatment, mining wastewater treatment, etc., and can solve the problem of long treatment time of microbial anaerobic or aerobic methods, large dosage of chemicals, secondary pollution, etc. problems, to achieve the effect of overcoming large sludge production, realizing flocculation and sedimentation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

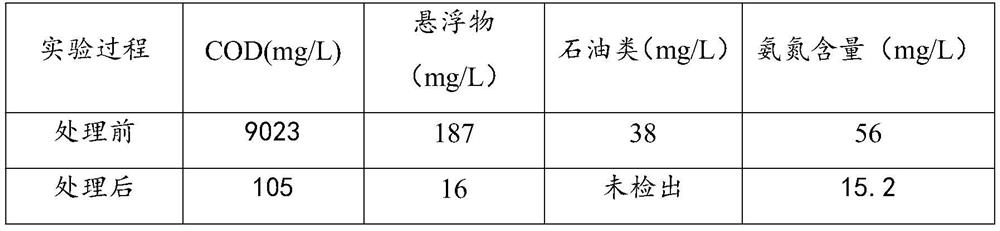

Embodiment 1

[0028] A treatment method for fracturing flowback fluid, the treatment method comprising the steps of:

[0029] 1) Pretreatment: under stirring conditions, add the oxidized flocculant potassium ferrate: 0.05% to the flowback liquid, keep stirring for 10 minutes, then let it stand for flocculation and precipitation;

[0030] 2) Electrochemical degradation treatment: the effluent after the pretreatment of the flowback liquid flows into the electrochemical process, adjusts the voltage and current, and controls the current density at 5mA / cm 2 Perform electrochemical degradation treatment;

[0031] 3) Electrochemical removal of heavy metal treatment: the electrochemical degradation treatment effluent flows through the heavy metal removal treatment process, the voltage and current are adjusted, and the current density is controlled at 15mA / cm 2 , carry out heavy metal removal treatment;

[0032] 4) Filtration treatment: the above-mentioned effluent after heavy metal removal treatm...

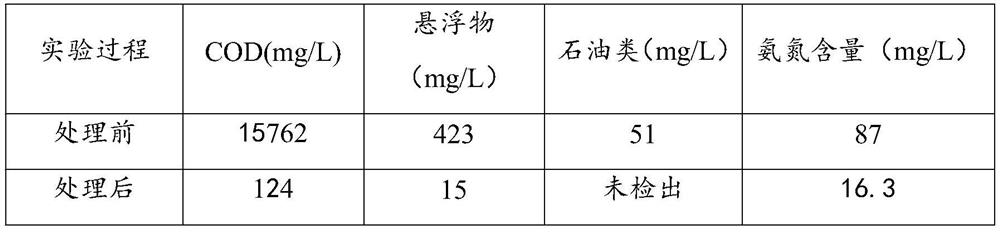

Embodiment 2

[0037] A treatment method for fracturing flowback fluid, the treatment method comprising the steps of:

[0038] 1) Pretreatment: under stirring conditions, add the oxidized flocculant potassium ferrate: 0.25% to the flowback liquid, keep stirring for 20 minutes, then let it stand for flocculation and precipitation;

[0039] 2) Electrochemical degradation treatment: the effluent after the pretreatment of the flowback liquid flows into the electrochemical process, adjusts the voltage and current, and controls the current density at 15mA / cm 2 Perform electrochemical degradation treatment;

[0040] 3) Electrochemical removal of heavy metal treatment: the electrochemical degradation treatment effluent flows through the heavy metal removal treatment process, and the voltage and current are adjusted to control the current density at 20mA / cm 2 , carry out heavy metal removal treatment;

[0041] 4) Filtration treatment: the above-mentioned effluent after heavy metal removal treatment...

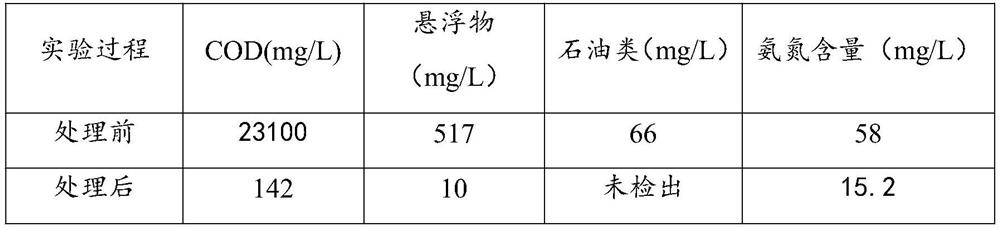

Embodiment 3

[0046] A treatment method for fracturing flowback fluid, the treatment method comprising the steps of:

[0047] 1) Pretreatment: under stirring conditions, add oxidized flocculant potassium permanganate: 0.5% to the flowback liquid, keep stirring for 30 minutes, then let it stand for flocculation and precipitation;

[0048] 2) Electrochemical degradation treatment: the effluent after pretreatment of the flowback liquid flows into the electrochemical process, adjusts the voltage and current, and controls the current density at 20mA / cm 2 Perform electrochemical degradation treatment;

[0049] 3) Electrochemical removal of heavy metal treatment: the electrochemical degradation treatment effluent flows through the heavy metal removal treatment process, and the voltage and current are adjusted to control the current density at 25mA / cm 2 , carry out heavy metal removal treatment;

[0050] 4) Filtration treatment: the above-mentioned effluent after heavy metal removal treatment flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com