A new type of lithium battery pole piece positioning intelligent welding device

A welding device and lithium battery technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of battery pack damage, the negative terminal of difficult batteries being flush with each other, and mutual bumping, so as to avoid mutual bumping and starting. Highly consistent, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

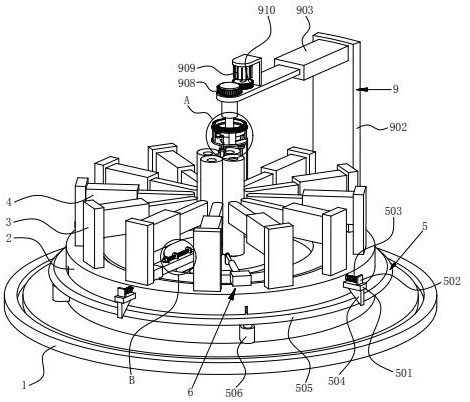

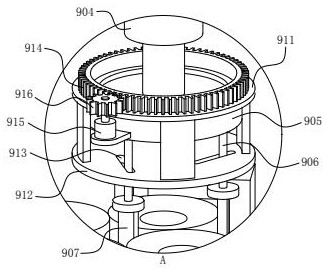

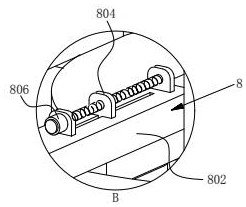

[0026] like figure 1 , Figure 4 and Image 6 As shown, this implementation provides a new type of lithium battery pole piece positioning intelligent welding device, including a base plate 1, a cylindrical table 2 is fixedly installed on the upper surface of the bottom plate 1, and a circular groove 201 coincident with its axis is opened on the upper surface of the cylindrical table 2; Several vertical plates 3 are evenly installed on the upper surface of the cylindrical table 2 around the circular groove 201. The surface of the vertical plate 3 is fixedly installed with a battery positioning rod 4 arranged radially along the circular groove 201. The battery positioning rod 4 is an electric telescopic structure; The outer end surface of the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com