Closed channel type electric dust remover

An electrostatic precipitator and channel-type technology, which is applied in the field of flue gas pollutant control, can solve the problems of no economical and efficient technology to solve the secondary dust emission of rapping, the inability to stably achieve ultra-low outlet dust concentration, and obvious secondary dust emission. Achieve the effect of improving internal space utilization, reducing energy consumption, and good space adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

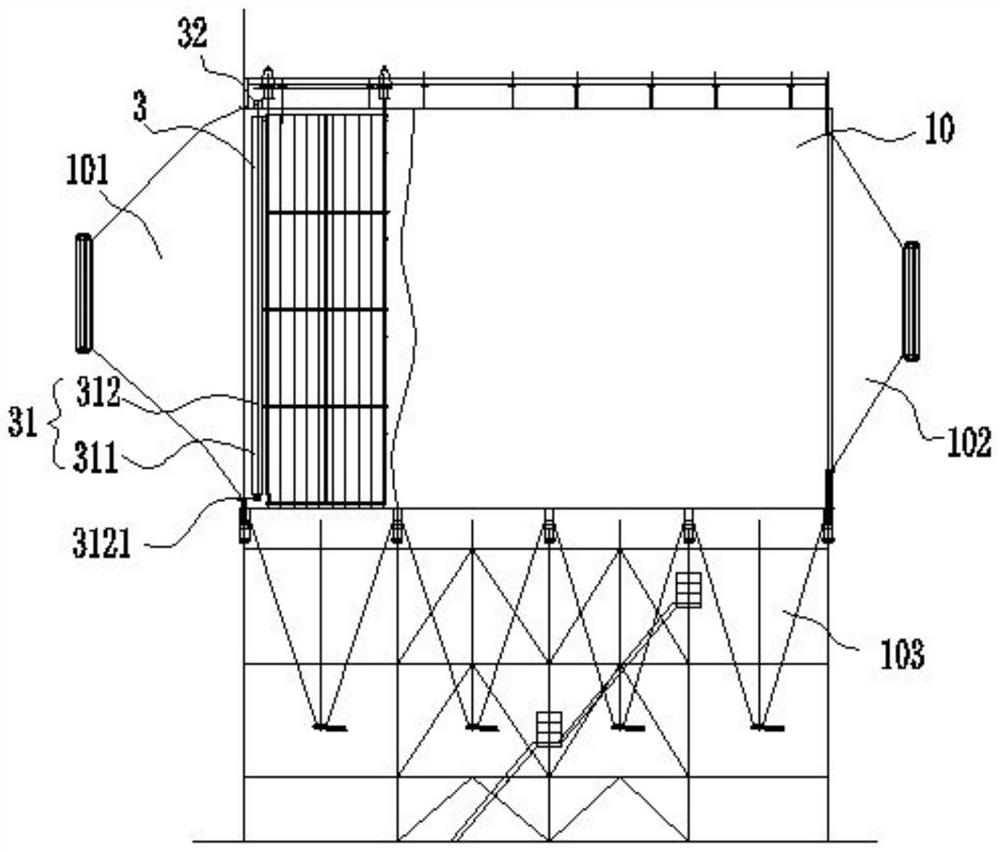

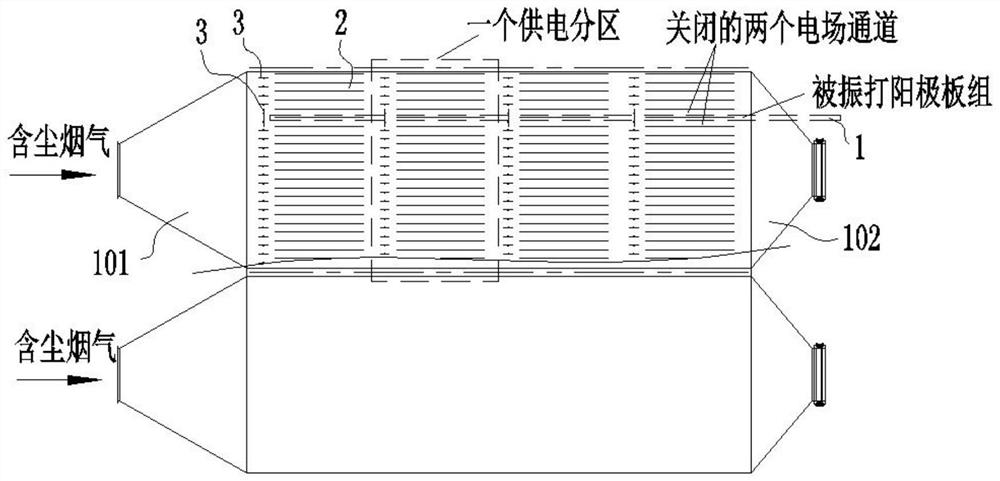

[0025] refer to Figure 1 to Figure 3 , a closed channel type electrostatic precipitator according to the present invention, comprising at least one dust removal box 10, the dust removal box 10 is provided with multi-stage electric field units along the flow direction of flue gas, and each electric field unit is provided with several rows of anode plate groups 1. An electric field channel 2 is formed between two adjacent rows of anode plate groups 1, and the outlet of the electric field channel 2 of the upper level electric field unit is connected with the entrance of the electric field channel 2 of the lower level electric field unit, and the electric field channel 2 is equipped with There are cathode wire groups 4, each electric field channel 2 is provided with a channel closing mechanism 3 at one end facing the flue gas inlet, and the channel closing mechanism 3 includes a blocking component 31 arranged at the entrance of each electric field channel 2, and is used to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com