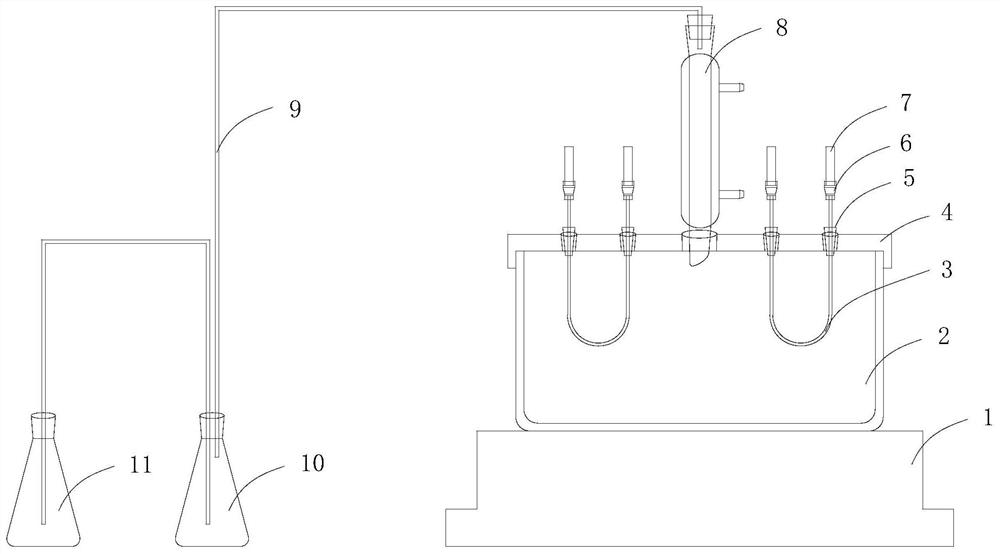

Dew point corrosion evaluation device with controllable condensation temperature

A technology of dew point corrosion and condensation temperature, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of uneven cavity temperature, low efficiency, difficulty in studying the relationship between dew point corrosion, etc., and achieve simple structure of the device , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

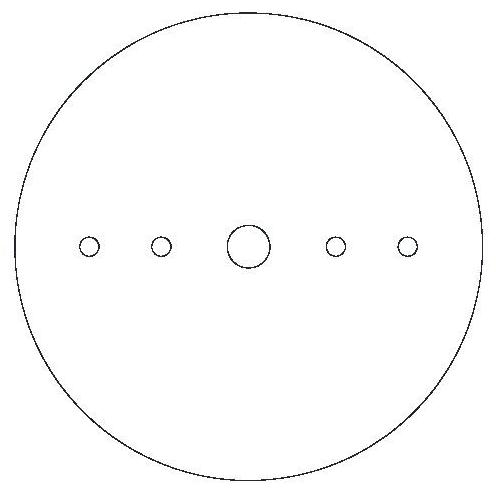

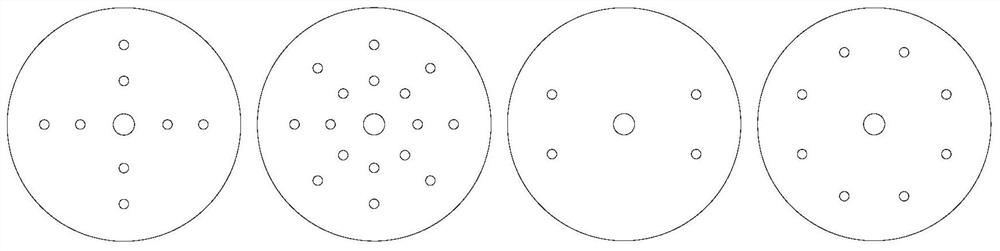

[0048] The hollow corrosion element has a hollow corrosion element A (304 stainless steel metal pipe) and a hollow corrosion element B (304 (CTS) stainless steel metal pipe (304 stainless steel metal pipe with surface treatment), each with a size of φ3×0.3mm. Add a hydrochloric acid solution with a mass fraction of 5%, and the temperature of the cooling medium passed into the stainless steel metal tube is 45°C. Use a DC resistance measuring instrument to test and record the resistance values of the hollow corrosion element A and the hollow corrosion element B respectively in the hydrochloric acid dew point corrosion environment. time changes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average corrosion rate | aaaaa | aaaaa |

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com