Graphene electromagnetic shielding composite material and preparation method thereof

A composite material and electromagnetic shielding technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of poor shielding performance of graphene electromagnetic shielding materials, achieve excellent intrinsic antimagnetic, reduce damage, and avoid pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

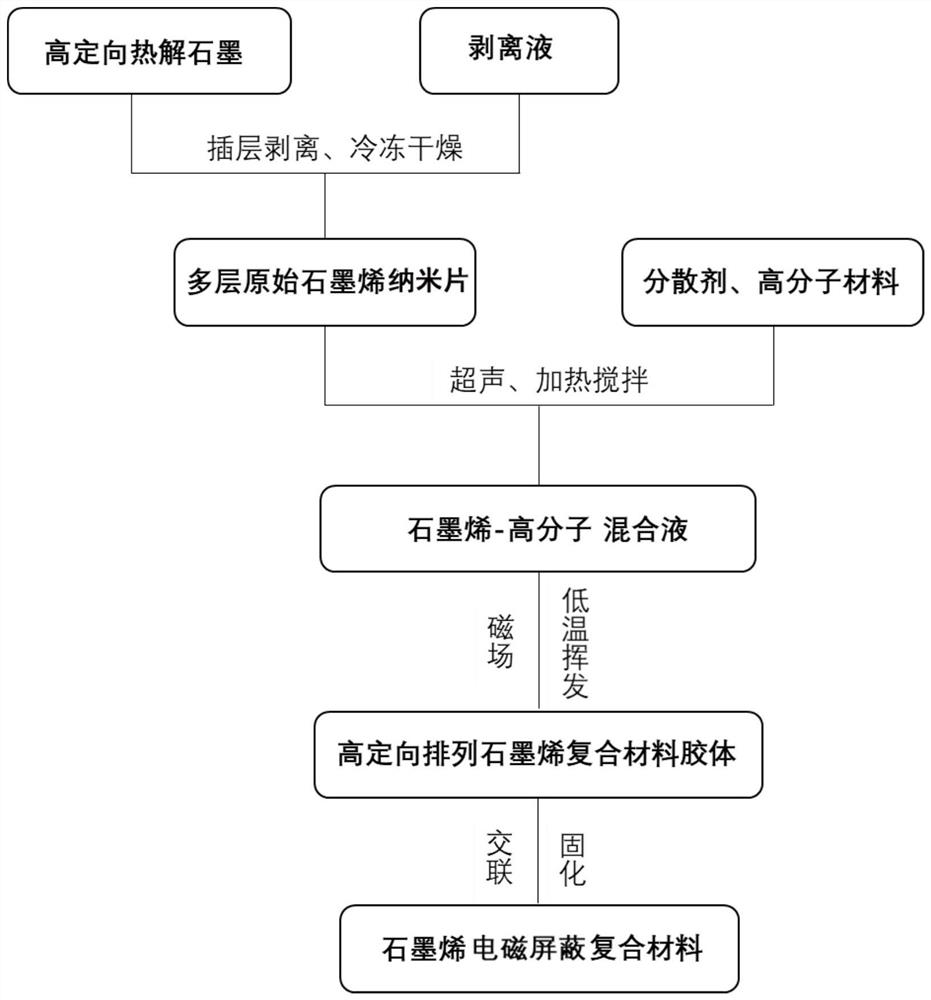

[0031] Such as figure 1 Shown, a kind of graphene electromagnetic shielding composite material preparation method of the present invention comprises the following steps:

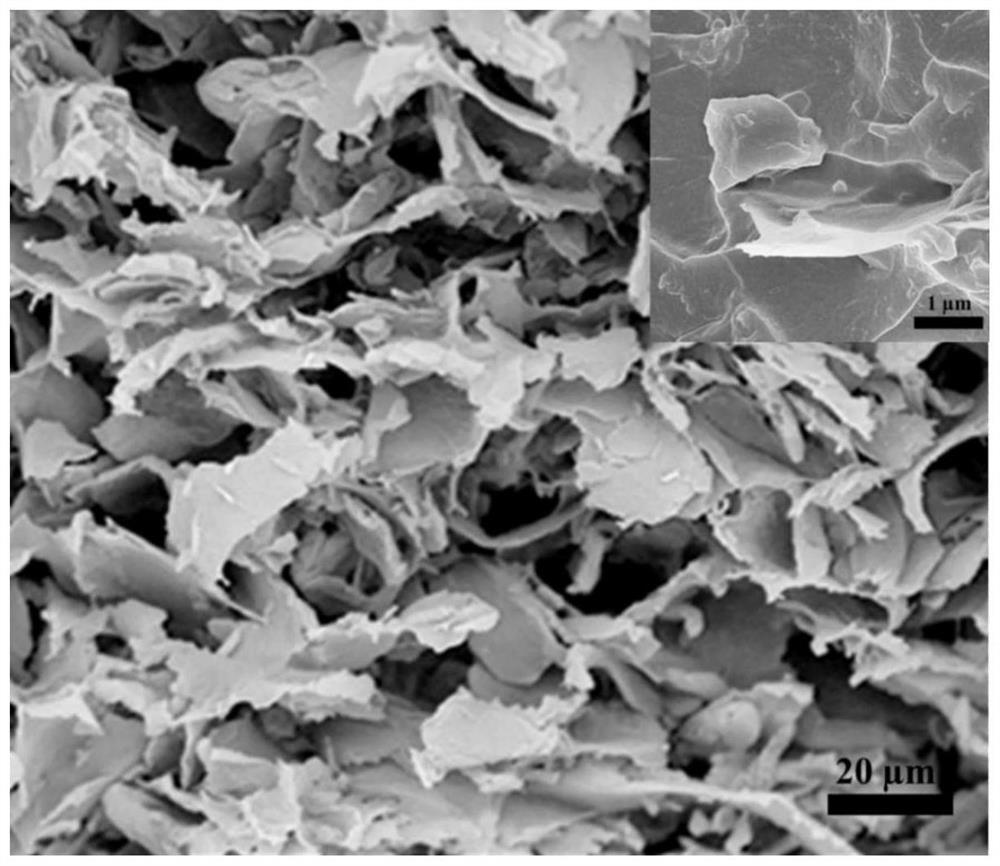

[0032] (1) Exfoliating highly oriented pyrolytic graphite by physical or chemical methods to prepare multilayer graphene nanosheet powder;

[0033] (2) Ultrasonic the multilayer graphene nanosheet powder to obtain dispersed graphene nanosheets, heat and stir the dispersed graphene nanosheets and polymer matrix materials in a polar organic dispersant, and proceed after each is uniformly dispersed Stir and blend evenly to form a graphene-polymer mixture;

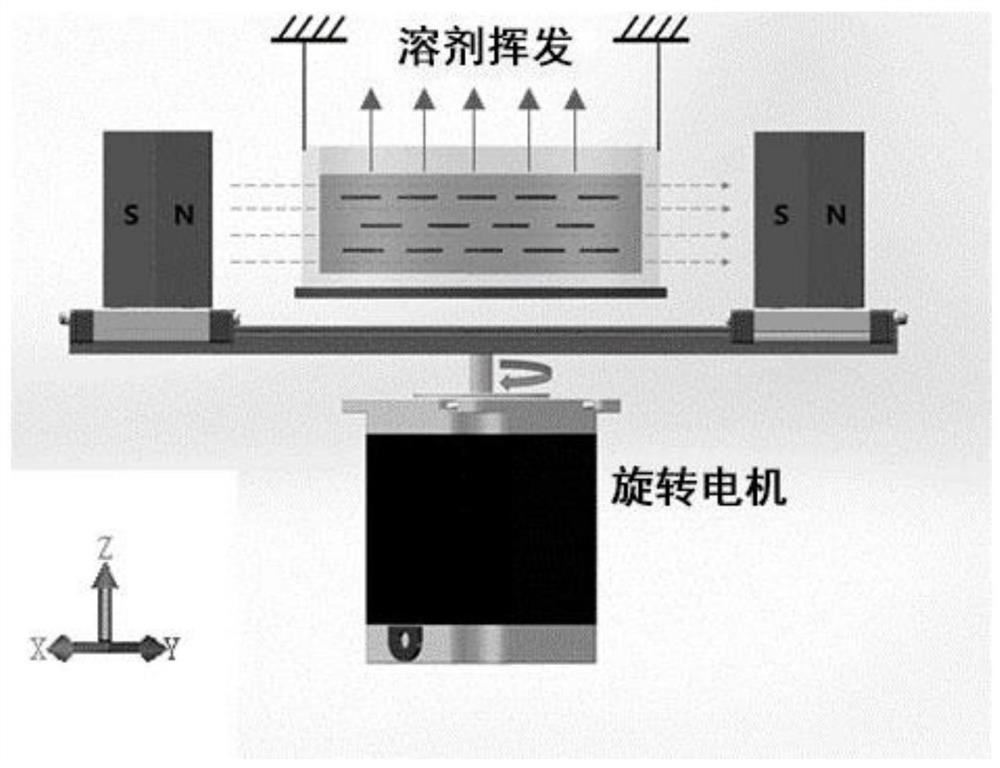

[0034](3) Inject the graphene-polymer mixture into the mold groove and use a constant temperature heating plate to heat it at a constant temperature, and at the same time apply a magnetic field outside it to make the graphene nanosheets achieve orientation in the solution, and wait until the organic dispersant volatilizes completely Finally, the highly ori...

Embodiment 1

[0045] Highly oriented pyrolytic graphite is prepared by intercalation exfoliation and freeze-drying techniques to prepare multilayer graphene nanosheet powder. Take a certain mass of multi-layer graphene nanosheet powder and epoxy resin (EP) respectively ultrasonically, heat and stir for 1 hour to disperse them in N-methylpyrrolidone, and blend them after they are uniformly dispersed to form graphene- Epoxy resin uniform mixture; inject the uniform mixture into a circular silicone mold with a diameter of 30mm, and use a ceramic heating plate to heat the bottom of the mold at a constant temperature of 45°C, and at the same time apply a horizontal rotating magnetic field with a magnetic field strength of 300mT to make the graphene nanometer The flakes are oriented in the dispersion, and after the solvent is completely volatilized, they are placed in a constant temperature blast drying oven at 120°C for 12 hours to dry and solidify, and finally a highly oriented graphene / ring wit...

Embodiment 2

[0049] Highly oriented pyrolytic graphite is prepared by intercalation exfoliation and freeze-drying techniques to prepare multilayer graphene nanosheet powder. Take a certain mass of multilayer graphene nanosheet powder and ultrasonically disperse it in N-methylpyrrolidone for 1 hour to obtain a dispersion, then add a certain mass of polyvinylidene fluoride and epoxy resin to the dispersion, and Blending is carried out by heating and stirring (60°C, 800rpm) and ultrasonication for 1 hour each, and finally a graphene-epoxy resin-polyvinylidene fluoride (PVDF) uniform mixture is formed; the uniform mixture is injected into a circle with a diameter of 30mm Shaped silica gel mold, and the bottom of the mold was heated at a constant temperature of 45°C with a ceramic heating plate, and a horizontal rotating magnetic field with a magnetic field strength of 300mT was applied at the same time to align the graphene nanosheets in the mixed solution. After the solvent was completely evap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Vertical size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com