Method and device for measuring diffusible hydrogen content in welding material deposited metal

A technology of deposited metal and welding materials, which is applied in the field of determination of the content of diffusible hydrogen in the deposited metal of welding materials, can solve the problems of threatening personal safety, brittle fracture of welded joints, and reducing the quality of welding products, and achieve great economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

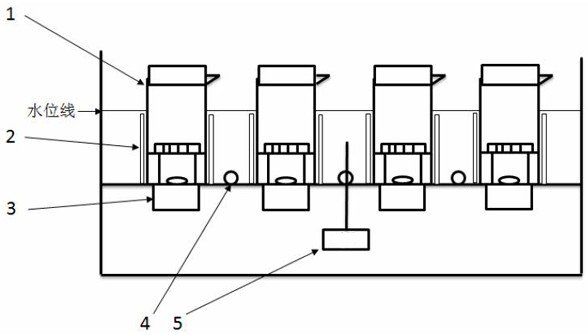

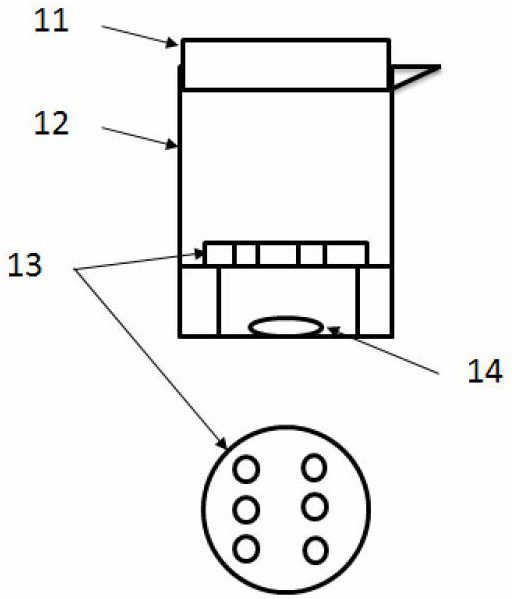

Image

Examples

Embodiment 1

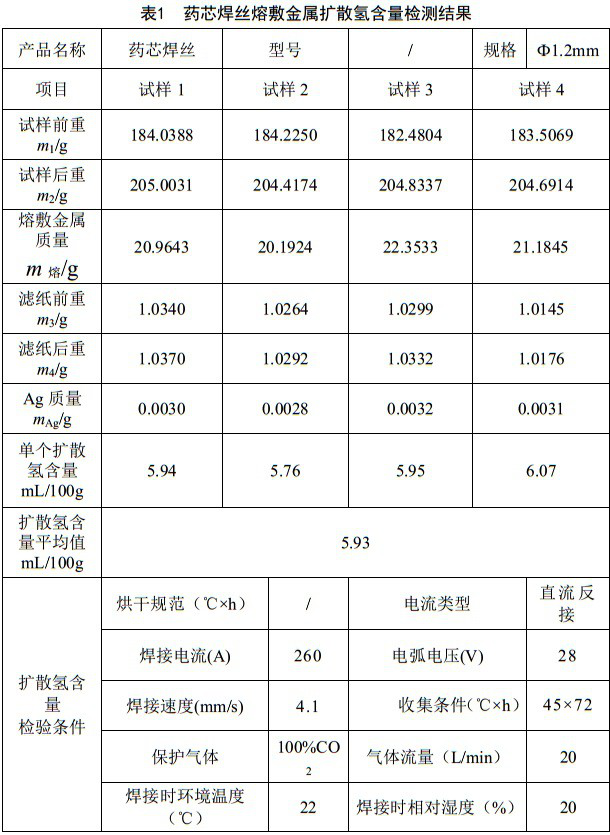

[0050] The test was carried out using the flux-cored wire, and the inspection records and results using the present invention are shown in Table 1. The test result using the mercury method was 5.88 mL / 100g.

[0051]

Embodiment 2

[0053] The test was carried out using a welding rod, and the inspection records and results using the present invention are shown in Table 2. The test result using the mercury method was 4.64 mL / 100g.

[0054]

[0055] It can be seen from the above examples that the results of the diffusible hydrogen content measured by the present invention are basically consistent with the results of the traditional mercury method. The measurement results of this method are accurate, and can well overcome the shortcomings of the traditional method.

[0056] The working principle of the present invention: this method is a replacement method to measure the content of diffusible hydrogen, which can chemically react with diffusible hydrogen to produce AgBr and NaNO, a special mixture of Ag. 2 solution, using Na after reaction 2 S 2 O 3 Remove excess solid AgBr, then use a filter to obtain the mass of Ag, and then calculate the diffusible hydrogen content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com