Adjustable jet pump

A jet pump, adjustable technology, used in jet pumps, non-displacement pumps, pumps, etc., can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

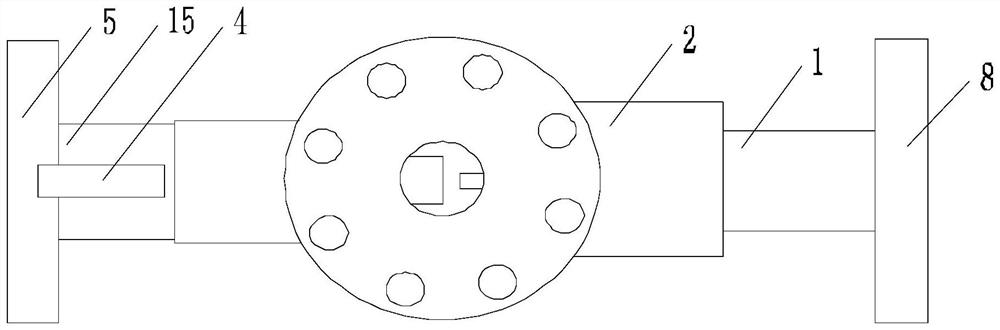

[0034] Such as Figures 1 to 8 As shown, this embodiment includes a pump body 1, the two ends of the pump body 1 are respectively connected with a first flange 5 and a second flange 8, and a connecting pipe 3 is provided in the middle of the pump body 1, and the pump body 1 On the inner wall at one end close to the first flange 5, there are intercommunicating diffusion channels 7 and throats 14, and on the inner wall at one end close to the second flange 8 of the pump body 1, two baffles 9 are arranged. , two baffles 9 form a conversion chamber in the pump body 1, and an arc-shaped base is provided on the inner wall of the bottom of the conversion chamber. An annular toothed belt 16 is arranged on the circumferential wall, and two driving motors are arranged on the side wall of the conversion chamber. The output end of the driving motor is provided with a driving gear meshed with the annular toothed belt 16, and along the axial direction of the runner 12 There are a plurality...

Embodiment 2

[0041] Such as Figures 1 to 8As shown, on the basis of Embodiment 1, this embodiment also includes a locking assembly. The locking assembly includes a planet carrier 44, a main gear 52, a fixed ring 50, a rotating rod 49 and a connecting rod 30. The main gear 52 is fixed on the bidirectional motor On one output end of 24, the main gear 52 is connected with the connecting rod 30 through the rotating rod 49, and the connecting rod 30 is connected with the worm wheel 21. The outer diameter of the rotating rod is larger than the diameter of the connecting rod 30, and a plurality of planetary gears 43 are distributed symmetrically in rotation. On the planet carrier 44, and a plurality of planetary gears 43 are meshed with the main gear 52, a pin 47 is provided in the middle of the end face of each planetary gear 43, and the pin 47 extends upward after moving through the upper part of the planet carrier 44, and on the pin A stop block 46 is fixed on the column 47, and the fixed rin...

Embodiment 3

[0044] Such as Figures 1 to 8 As shown, in the guide cylinder 18, the nozzle 19 is connected to the butt pipe 36 through a stainless steel telescopic pipe 27. In order to ensure the connection stability of the connection between the nozzle 19 and the butt pipe 36, a There is a movable sealing ring 26, so that the stainless steel telescopic tube 27 is always isolated from other areas in the positioning groove 28, preventing the entire device from being unable to continue to use after the stainless steel telescopic tube 27 fails; It is relatively short, in order to avoid excessive displacement of the butt joint 36 and form a hard impact on the butt ring 10 or the baffle 9, this technical solution is provided with a plurality of travel switches 34 on the end surface of the positioning groove 28 close to the butt joint 36 , when the movable sealing ring 26 on the butt joint 36 is in contact with the travel switch 34, the controller can control the two-way motor 24 to stop. It sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com